Holzwerke van Roje installs a new planing mill in its existing facility at the Oberhonnefeld-Gierend location (Rhineland-Palatinate).

Holzwerke van Roje strengthened its own finishing with the installation of an automated planing mill last year. Connected to the sawmill, around 50% of the main product is processed further here. The company invested around 3.7 million euro for this purpose in the new plants.

Satisfied with the cooperation and results of the project (from left): Planing Mill Manager Eduard Dück, the Managing Director of Holzwerke van Roje, Gerhard Hauschulte and Kallfass Director Hans Haist.

Holzwerke van Roje GmbH & Co. KG operates a sawmill at its Oberhonnefeld-Gierend location (Rhineland-Palatinate) with an annual timber output of around 450,000 solid cubic metres. 90 % spruce and 10 % Douglas fir are currently processed, but Managing Director Gerhard Hauschulte estimates that pine will be added to this again to ensure the availability of timber logs in future. A planing mill and pellet production facility producing 80 000 t per annum are attached to the saw mill, and a cross-laminated timber production facility is currently under construction. Holzwerke van Roje currently has a workforce numbering 160 employees.

The planing mill was completed last year as a completely new installation at the plant and adapted to meet the special needs of sawmill production. The objective is to clearly strengthen processing of sawn timber. Up to 70,000 m³ of planed workpieces will be produced per annum from the main product, which is equivalent to about 50 % of the main product produced in the sawmill.

Kallfass GmbH in Baiersbronn delivered the complete fully automated mechanisation technology for the new Rex “Big Master” planing machine from Georg Schwarzbeck GmbH & Co KG in Pinneberg, including a wrapping station. A cupping and moisture meter, a “Golden Eye” quality scanner from Microtec, a marking station from REA JET and the strapping unit from Fromm are integrated in this facility.

Kallfass planing machine feeder

Infeed side of the REX “Big Master” planing machine

During conversion planning in April 2020, the two existing planing lines were dismantled in June of last year. Kallfass began at this time to install parts of the mechanisation technology in cleared areas of the facility while production was still underway. Commissioning of the complete plant then followed at the beginning of September. The plant was producing around 400 m³ of planed workpieces a day in 2 shifts by the end of the year.

Production at the van Roje sawmill is very customer-oriented, serving buyers all over Europe. There is a focus on markets in the Netherlands and United Kingdom with the majority of orders for lengths exceeding 6 m. Van Roje has also concentrated on the European market in recent years, exploiting domestic sales opportunities freed through the booming US sawn timber market. Stock dimensions up to 620 mm and log lengths of 3 to 14 m are cut. The maximum length in the timber sorting system is 8 m. Frequent product changes of up to four times an hour are part of everyday production at van Roje. This means that, when it comes to the cross section and length, a broad variety of dimensions is encountered in the planing mill, and it is necessary to work with relatively small batches. The smallest batches frequently involve only two packages per dimension. The planing mill therefore needs to be very flexible and produce everything from roofing battens with numerous special dimensions to raw solid structural timber. The maximum dimensions of completely planed products at van Roje are 150 x 320 mm. In particular, the maximum possible length of up to 8 m means the plant differs from the majority of industrial planing mills.

Minimum adjustment times and “profile management” on the planing machine

The flexibility required at van Roje is reflected in the configuration of the Rex “Big Master” planing machine: With ten planing cutterheads (four horizontal and two vertical tools and four individual chamfering tools for an all-round workpiece chamfer) finished product widths of 60 to 400 mm and heights of 15 to 200 mm can be created with continuously adjustable feeds of 30 to 150 m/min. In addition to planing and profiling, single and multiple cutting to length of the workpiece is also possible, and van Roje uses up to five saws.

Different board widths can be processed in layers simultaneously on the machine with only narrow gaps between them. Width adjustment is servo controlled at an adjusting speed of 20 mm/s. The Rex profile management control system enables storing of working shaft positions which have been configured. If a particular profile needs to be repeated, the operator, after deploying the required tools, can select the profile using the assigned workpiece name. The machine then automatically moves each spindle into the correct position. Shafts not required for a procedure go into idle mode, leading to a palpable reduction in the electric power input.

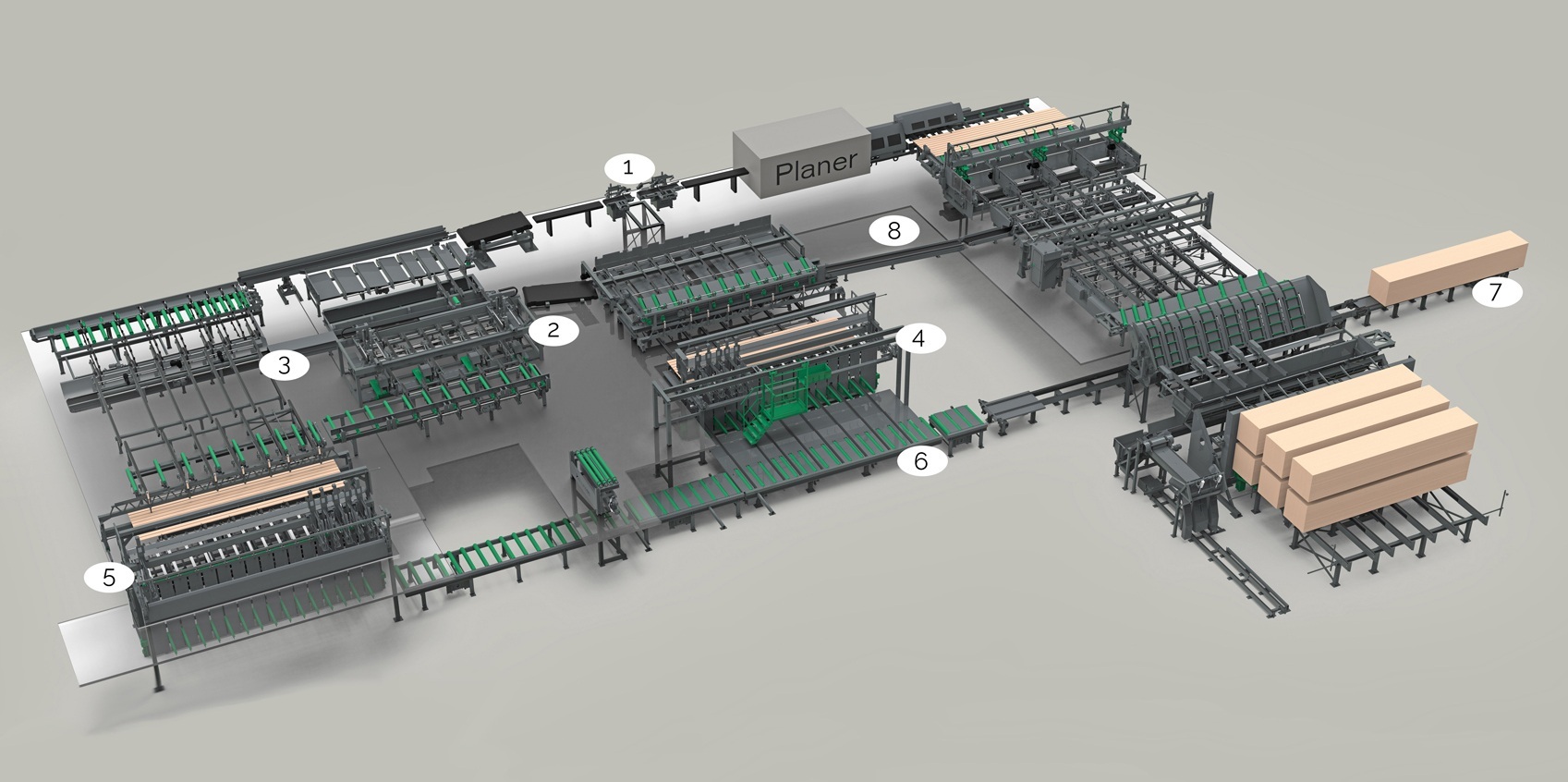

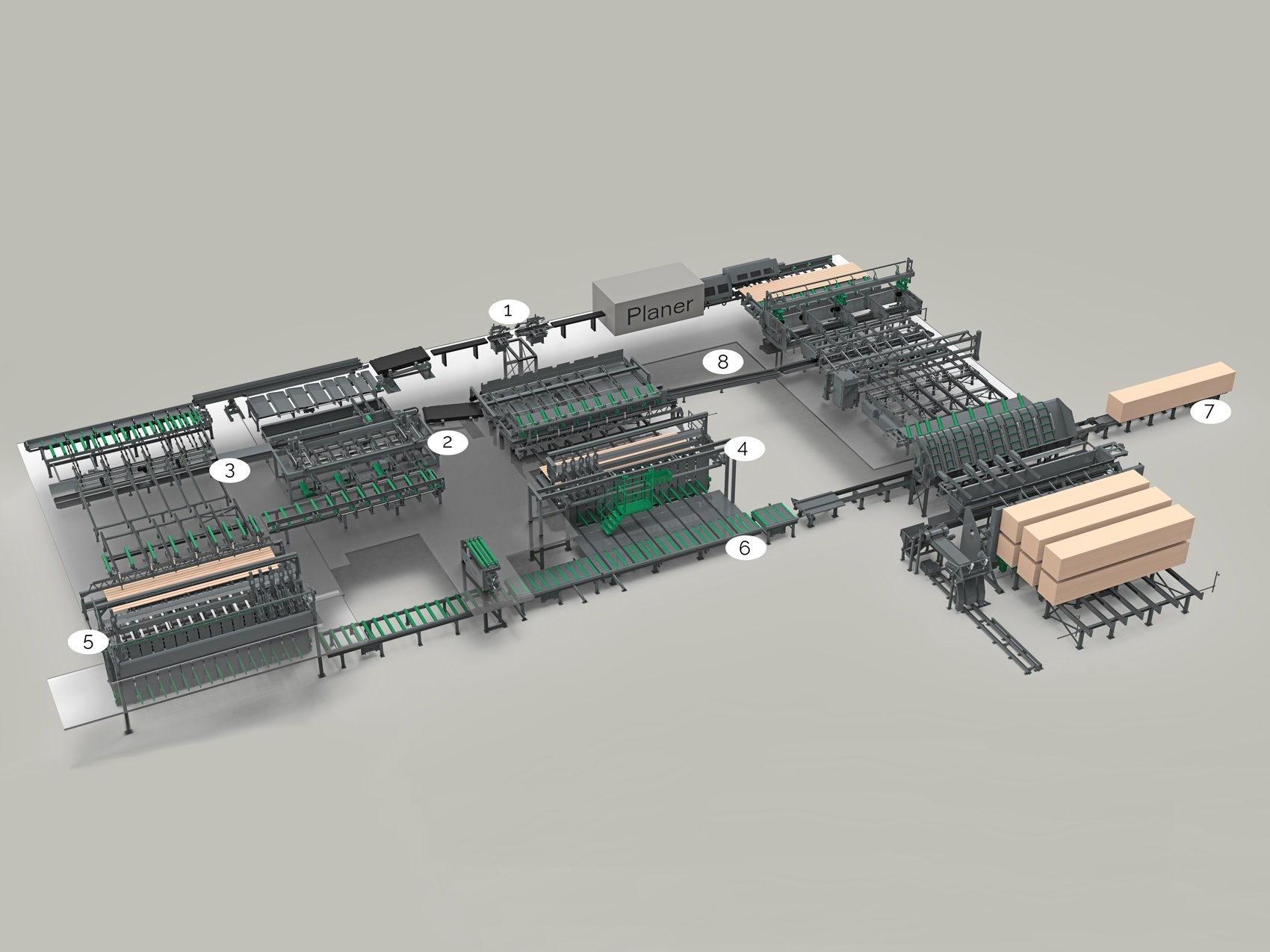

Schematic depiction of the van Roje planing mill. The material moves from charging and tilt destacking via a sorting conveyor to the Kallfass planing machine feeder. A triple cross-cut saw is installed upstream. A Microtec quality scanner (1) is installed behind the Rex planing machine. Options then available are a bundling station (2) and marking station (3), after which the product is transferred to the wrapping and strapping station (6) by one of the two stackers (4 and 5). The packages are output to the right onto the acceptance point in front of the plant (7). Ejection of material from the sorting conveyor is possible (8).

Compact mechanisation for workpiece lengths up to 8 m

Kallfass installed a fully automated mechanisation solution here with an interface connection to the van Roje ERP system (Timbertec). With regard to operation of the planing mill, aside from the plant operator and a stand-in, only two other employees are required for wrapping.

Following tilt destacking of the raw material packages (presorted in the sawmill in the case of freshly cut material) and separating, unsuitable material can still be ejected from the sorting conveyor prior to planing machine charging. The plant can therefore also be used for stacking of drying packages. A growth ring detector (cupping detector) integrated on the unscrambler and a moisture meter from Microtec combined with a board turner contribute to the improvement of planing quality. Timber that is too moist can be ejected and raw material turned, depending on the growth ring position.

A freely positionable triple cross-cut saw is installed upstream of the planing feeder and frequently used at van Roje. Cutting upstream of the planing machine achieves absolutely fringe-free cuttings. The feeding of the planing machine achieves 50 cycles/min. Directly downstream of the planing machine, the workpieces pass through a “Golden Eye” scanner from Microtec that organises the product into strength classes C16 and C24. They can then be separated from each other in the passage and either sent directly to one of the two stackers or, previously, to a bundling unit. Adaptation of CE certification for mechanical sorting is currently underway at van Roje. The customer can therefore be offered a combination of mechanically and visually sorted planed workpieces.

Four strapping stations are available at the bundling unit. Up to ten stick bundles can be created there every minute. Packages can be produced on stackers equipped with stick magazines at a rate of 10 layers/min.

Flexibility and rapid dimension changes are core requirements of mechanisation at van Roje, given the frequent product changes involved. A dimension change upstream of the planing machine takes around 1 minute under practical conditions and 20 seconds downstream of the planing machine, meaning each dimension change takes a total of 1 to 2 minutes. The entire mechanisation is designed to provide a feed of 200 m/min. The compact mechanisation layout can accommodate timber lengths of 8 m with ease, while the minimum length for raw material is 2.00 m and 1.80 m for planed products. Package lengths up to 8 m can also be wrapped on the package wrapping unit.

CLT marketing from May

The planing mill is not only designed for finishing the main product, but also represents an important downstream production section for the cross-laminated timber production facility under construction. B sorters for lamellas originally created in the sawmill for other products are calibrated and quality sorted here for use as top layer lamellas in cross-laminated timber (CLT). Lamellas cut especially for the top layer in the sawmill are planed directly in the cross-laminated timber plant. Raw lamellas created from side products are planed and quality sorted for use as (non-dovetailed) transverse layers in the CLT. The option to create different board widths in a layer on the planing machine really pays off here. Exploitation of side products can therefore be considerably increased.

When compared to the usual contemporary production process in CLT manufacturing, the entire production process is to be optimised for resource efficiency, from production of raw lamellas in the sawmill to the completed CLT construction element. Particular attention is also paid to the conservation of raw materials in the cross-laminated timber plant (which bears the project name “Cross Works”). Window and door cutouts are returned to the raw materials cycle again through a treatment process. The cutouts created are separated and recycled in the cross layer. These efforts to achieve resource efficiency have also encouraged support of the overall project through funding of EUR 5,993,815 from the environmental innovation programme of the German Federal Ministry of the Environment. 75,000 m³ CLT should be manufactured annually as of April in 2-shift operation. van Roje wants to begin marketing its cross-laminated timber in May.

Kallfass planing machine feeder

Infeed side of the REX “Big Master” planing machine

Schematic depiction of the van Roje planing mill.

Charging and tilt destacking from Kallfass.

The view into the front part of the van Roje planing mill facility. The bundling unit is in the foreground, with the feed for the first stacker behind. Visible in the background are (from the right) the sharpening center, the noice-protection cabin of the planing machine and the “Golden Eye” scanner.