There has been a new face in the European sawmill industry for a year now: Grupo Losán, from La Coruña, Spain, decided to invest in a sawmill in Soria. What is particularly special about this is that the company mainly relies on technology made in Germany.

German technology in Spain: Linck has installed a profiling line at Grupo Losan eine Profilierlinie, Kallfass delivered the mechanisation and the box sorter with 45 boxes

The company, which was founded in 1964 by the brothers Manuel, Luis and Emilio López Sánchez, is specialised in the production of particle boards, medium-density fibre boards (MDF), veneer panels and plywood panels, and it has eleven production sites in Spain, Romania, the Netherlands, the US and Chile. The biggest factory for particle boards is located in Soria in the north-east of Madrid, approx. a two-hour drive away, and this is where the new sawmill started production in March 2017. Jorge A. González Sánchez, plant manager in Soria, describes the motivation for this investment in an interview with Holzkurier: "We wanted to diversify our product portfolio and broaden our position on the market. In addition, we can use the scrap wood to supply our particle board factory and the biomass-fired CHP plant in Soria."

Located right where the wood grows

When travelling from Madrid to Soria, the barren landscape makes one wonder how the sawmill is actually supplied with logs. However, Soria is located on a high plateau at more than 1,000 m above sea level and right in the middle of one of Spain's pinewood growth areas. Losán mainly processes the local species Pinus pinaster (maritime pine) and Pinus sylvestris (Scots pine). Pinus radiata (Monterey pine), which is characterised by greater firmness, comes to Soria from the Basque region further up north. Thus, the sawmill does not have any problems at all when it comes to its supply of logs. In addition, from a logistics point of view, Soria is ideally located with regard to Madrid, Valencia and Barcelona.

„It was particularly important for us to rely completely on our suppliers and to purchase high-quality machinery. This is why we decided to purchase technology made in Germany."

Jorge A. González Sánchez, plant manager in Soria

Reliable suppliers

When the company selected its suppliers, it decided to rely nearly exclusively on technology made in Germany. With the exception of a few installations performed by Losán itself, Linck from Oberkirch,Germany, acted as a general supplier and was responsible for the log yard and sawing line. Other major suppliers of the new sawmill include Kallfass from Baiersbronn-Klosterreichenbach, Germany, Vecoplan from Bad Marienberg, Germany, Sennebogen from Straubing, Germany, and Mahild from Nürtingen,Germany. "We wanted only the best suppliers to ensure that the new sawmill could start production without any problems," explains González the decision which was definitely the right one as he confirms. "We are highly satisfied with the suppliers. This ensures a quick start of production." And, indeed, the sawmill began operating in May 2017. After just two months, a second shift was introduced, and a third one only six months later. Next month, the company wants to start a fourth shift.

The company originally intended to produce 50% construction timber (dimensions adapted to constructional timber work and furniture-making applications) and 50% packaging material. However, due to the high demand for sawn timber for pallets, this area currently accounts for 90% of the sawmill output. "The market has calmed down a bit, but packaging material still sells very well," says González. As already mentioned, the log yard is where the equipment supplied by Linck can be found. Material handling equipment made by Sennebogen supplies the feed table with logs. After their separation, the logs pass through a Microtec scanner. Logs that are too thick or thin are automatically sorted out.

The subsequent debarker made by Valon Kone is equipped with eight feed rolls – four of which are driven. "This is particularly advantageous for short logs," explains Martin Huber. He is the head of project planning at Linck and in charge of the installation at Losán. As a next step, another 3D scanner made by Microtec determines the master data for sorting the logs into one of twelve boxes. Under the system, the bark disposal system and the concrete boxes have been installed by Losán.

Full optimisation – value before volume

The debarked logs are stored only as briefly as possible (pinewood develops blue stains rather quickly) before they are transported to the sawing line. The sawing line and the sorting station are located in an existing hall which Losán has expanded by 30 m. The Linck line is intended for logs of 2 to 4.6 m and a top diameter of 12 to 40 cm. Due to the specialisation in pallet products and because of the raw material (maritime pine can be rather crooked), Losán mainly produces short timber with a length of 2.5 m. In the log infeed area, Linck has installed a partition that can be lifted and lowered to ensure that even short logs reach the separating system in a neat manner. The feed rate of the profiling line can be continuously adjusted between 30 and 100 m/min. Via a conveyor, the logs reach a Microtec 3D scanner. The resulting data are used by the Linck full optimisation system to determine the optimum cutting pattern. "All of the sawn timber dimensions and the corresponding values are stored in the program. The optimisation system calculates a suitable cutting pattern in terms of the board width, length and thickness for the main product and sideboards," explains Martin Huber. This is done based on the following rule: Value before volume. The cutting process is based on a specified number of finished products. The logs can be fed into the system either from their top end or butt end.

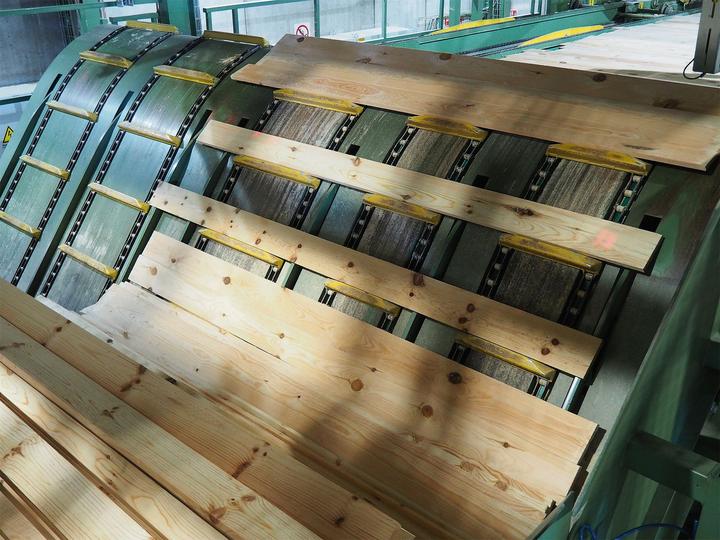

The infeed system brings the logs into their correct position in line with the optimisation data. The first chipper-canter produces two plane surfaces. After a 90° rotation of the cant, the first profiling group is the next station. In a single working step, a chipper-canter, a profiler unit and a circular saw work on the cant. The profilers profile the sideboards while the circular saws cut off up to three sideboards on every side of the cant. Then, these sideboards are separated and transported to the sorting system provided by Kallfass.

After another 90° rotation, a profiler unit in the resawing group once again produces sideboards. This is then followed by the Linck multi-blade circular saw with fixed spacing. It cuts the wood into sideboards and the wane-free main product (pallet boards). "The line has been designed for an annual output of 250,000 solid cubic metres in two shifts. However, this depends strongly on the raw material. In the case of large diameters, the feed rate must be adjusted accordingly," explains Huber.

Discharge of the sideboards after the primary processing group and transport towards the Kallfass sorting system.

An employee checks the quality of the sawn timber.

Cycling-in of the boards by the way of a tong loader for the transfer towards the boxes.

Transfer to the sorting system

Via a roller conveyor with transverse discharge, the main product and sideboards are transported to a joint buffer conveyor. This is where Kallfass takes over. In line with the configuration of the sawing line, the sorting system has been designed for sawn timber with a length of 2 to 4.6 m. The board width can be between 70 and 250 mm and the thickness between 17 and 120 mm. A separation station and a curved conveyor transport the sawn timber to an assessment station. A worker classifies the sawn timber according to its quality. If necessary, the boards can be cut to length by way of a chop saw.

A tong loader feeds the individual items into the sorting system in a cycled manner: The loader, which works like tongs, grips the individual boards from the layer of boards and places them onto the carrier conveyor. A measuring system determines the length, width and thickness of the boards while they pass crosswise through the system. They are then sorted into one of 45 inclined boxes. "The system has a capacity of 100 cycles per minute," explains Dominik Hauser of Kallfass. "The grades for the sorting program can be entered at the office via an Excel table and supplied to the sorting program via a network. The operator can transfer the grades into the current program, e.g. if new grades are added. Conversely, the grade tables can be output as CSV files which can then be read into and edited in Excel," adds Hauser.

Kallfass has installed 45 boxes for sorting the sawn timber - further expansion is possible

Stacking of boards with different widths per layer

The control system automatically indicates the fill levels. They are monitored by the workers of the sorting system and also by the operator/supervisor of the sawing line via a screen. Once a box is full, it can be emptied at the bottom. In a first step, the boards are separated by way of a step feeder and then by way of a typical separator. The sawn timber then reaches another inspection station where the quality can be reassessed. The handling system forms layers in line with the package width. A multiple circular cross-cut saw cuts the sawn timber to the required length. For this purpose, a zero saw and four variable chop saws are available. The layers of sawn timber, which has been cut to a fixed length, are stacked with the aid of stacking tongues to form a package. This is where Kallfass has installed an automatic batten positioning system with eight magazines. According to Dominik Hauser, the system has an output of up to twelve layers per minute. The stacking system can also form layers with different board widths.

A hoisting unit transports the complete package to the next lower level where it is strapped and provided with a package note. In a next step, the pallet products must be treated in accordance with the applicable regulations. To do so, a machine manufacturer from Soria has installed a dip tank. In addition, Mahild has provided four drying chambers.

Separation after the boxes have been emptied

Inspection prior to stacking

Up to 5 chop saws in the multiple cross cut saw ensure the correct length of the boards

Exact size: The straight layers prove the boards have been cleanly cut and stacked

Further extension possible

Although Losán was a novice in the field of sawmill operations, the company says that it quickly reached a high output, which was also thanks to the excellent support provided by the machine suppliers. "In our best month so far, we realised an output of 20,000 solid cubic metres," says González with pride. However, the sawmill is not the end: The managing director is already thinking about further investments. "We would like to expand our business here. The next step could be a planing system or a pellet production line," he concludes.

Pictures and text Martina Nöstler, Holzkurier 38/2018