Extraordinarily smooth running

Trimmer saws

The trimmer saw is primarily used upstream of a sorting system where it is responsible for cutting workpieces to size on preconfigured grid lengths and notching to mark any flaws.

Easily adjusted saw units

Short setup times

The trimmer saw is available in two versions, depending on the desired cycle rate. The saw linkage is pneumatically powered at cycle rates of up to 80 pieces/min, while a servo drive is recommended at higher outputs of up to 170 pieces/ min. Each saw unit is equipped with its own drive and, thanks to ball guides, can be easily configured for length adjustment and service purposes. This achieves a clear reduction in setup and maintenance times.

Solid structural design

Very smooth running

A solid design means that the trimmer saw runs extraordinarily quiet and smoothly, even at high speeds up to 170 pieces/min, thus ensuring a constant, reliable process throughput.

Optional equipment

The added bonus for your success! This equipment allows you to enhance your product quality while simultaneously reducing changeover times and personnel costs.

Efficient process sequence

WANE SCANNER

Wane scanners are generally used prior to sorting. In addition to visual detection of the wane to be removed from timber, scanning also determines the length, width and thickness and stores these dimensions as information for subsequent trimming.

Efficient trimming

FLEXIBLE SERVO ALIGNMENT

In order to work efficiently, cutting losses must be avoided when notching flaws on workpieces. A maintenance-friendly flexible servo alignment is installed directly upstream of the trimmer saw for this purpose. Regardless of the preconfigured grid lengths, the servo alignment pushes the workpieces accurately and continually towards the desired cutting position.

What can we do for you?

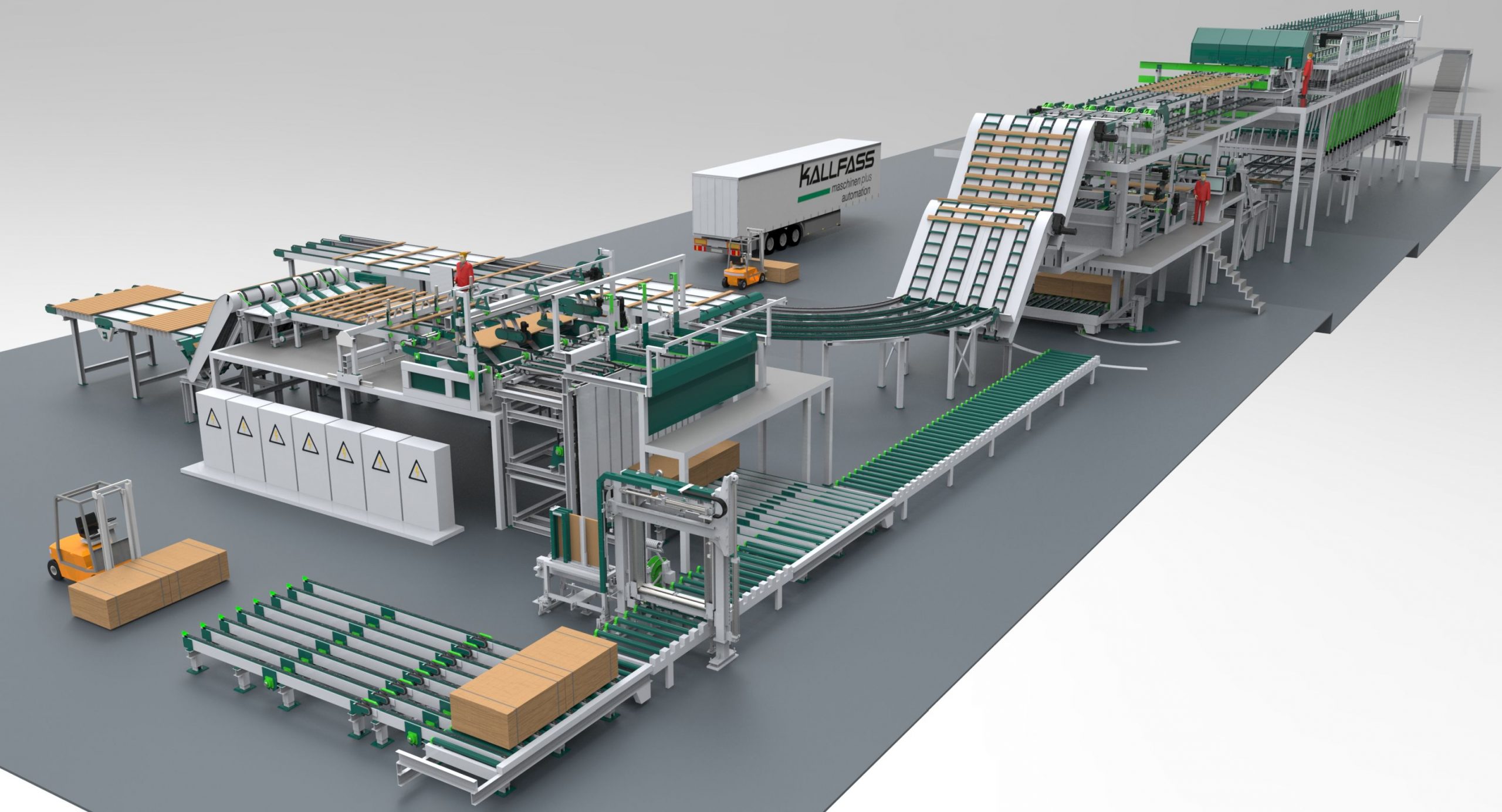

We regard ourselves as a solution partner that assumes responsibility, supporting you from initial consultation and the planning phase right through to successful commissioning of the production line. We train your operating personnel, provide you with comprehensive technical documentation and continue to support you after commissioning with advice and practical help.

Optional equipment

The added bonus for your success! This equipment allows you to enhance your product quality while simultaneously reducing changeover times and personnel costs.

Efficient process sequence

WANE SCANNER

Wane scanners are generally used prior to sorting. In addition to visual detection of the wane to be removed from timber, scanning also determines the length, width and thickness and stores these dimensions as information for subsequent trimming.

Efficient trimming

FLEXIBLE SERVO ALIGNMENT

In order to work efficiently, cutting losses must be avoided when notching flaws on workpieces. A maintenance-friendly flexible servo alignment is installed directly upstream of the trimmer saw for this purpose. Regardless of the preconfigured grid lengths, the servo alignment pushes the workpieces accurately and continually towards the desired cutting position.