Constant pressing force –

Clean pressing pattern

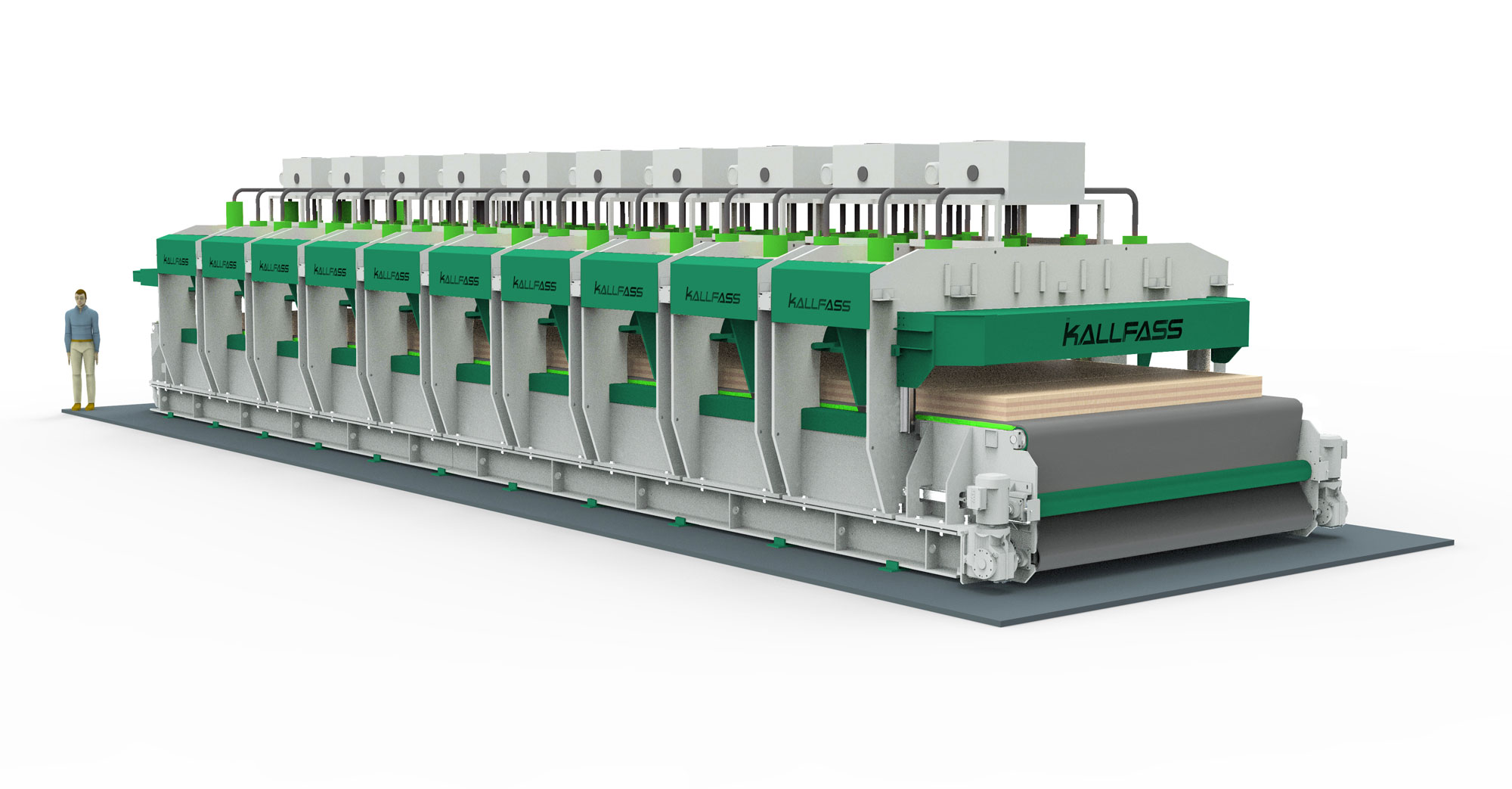

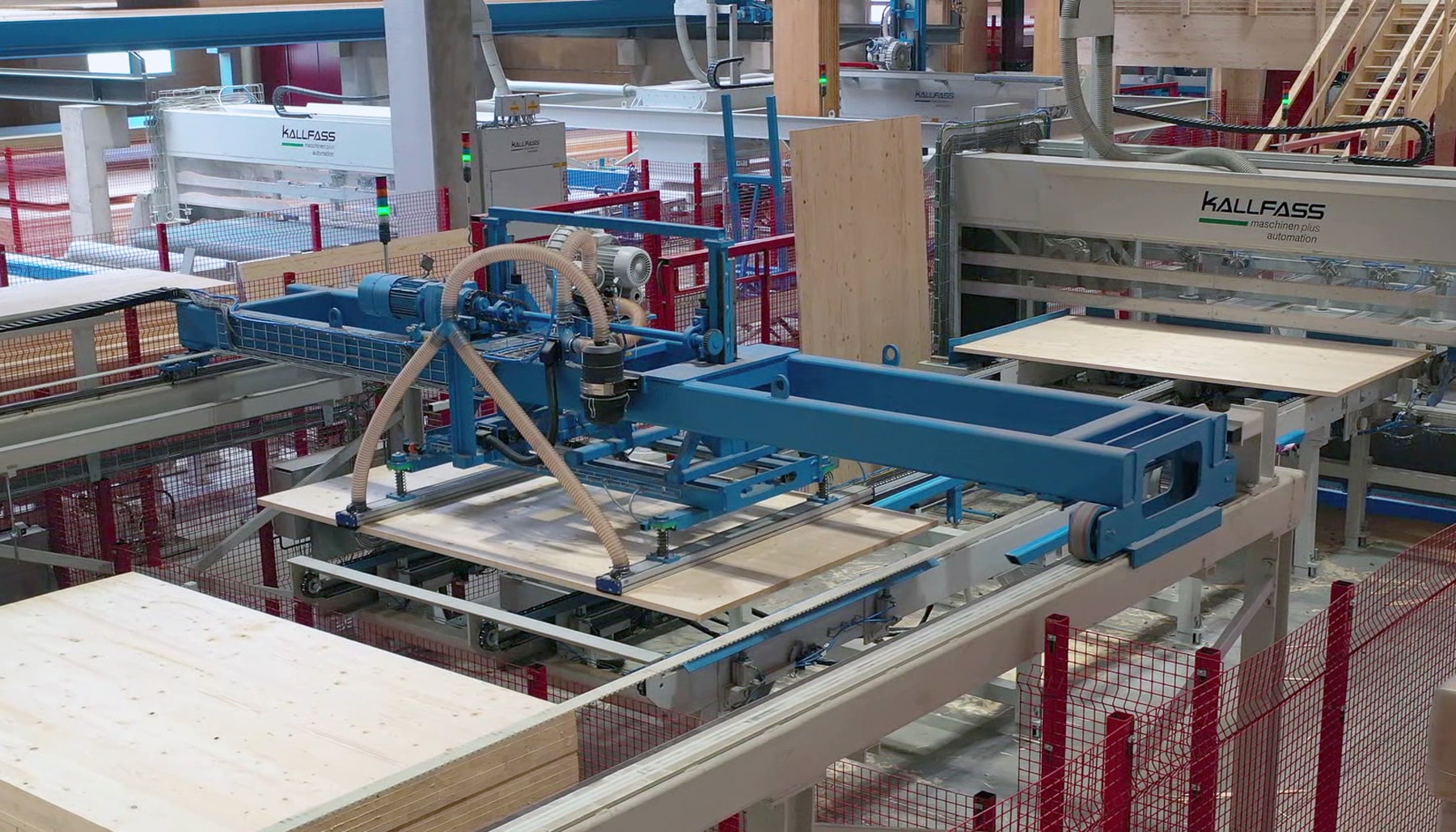

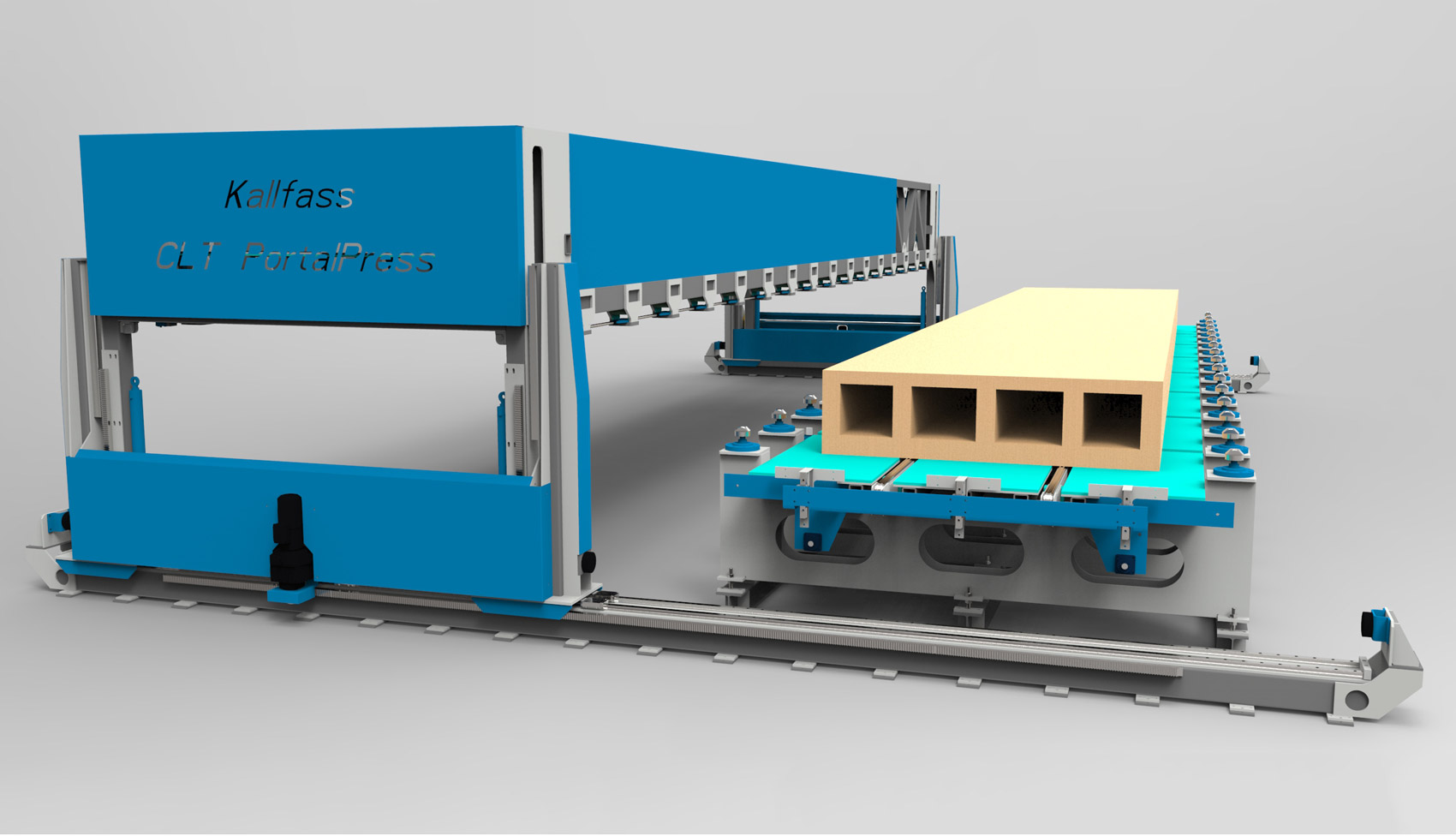

The CLT press is used to apply constant pressure for pressing multi-layer panels together. The focus during development was on product precision and reliable achievement of a zero joint.

High process availability

Short cycle times

Intelligent hydraulic system

CONSTANT PRESSING FORCE

The hydraulic system enables the achievement of quasi-isobaric pressing force because, in addition to vertical pressure units, transverse pressure units can also be fitted if desired. As a consequence, pressure control ensures a constant pressing force of 1N/mm², even where a maximum board width of 3.6 m is involved.

Board dimensions (min./max.):

Length: 8,000 mm – 16,000+ mm

Width: 2,200 mm – 3,600 mm

Height: 60 mm – 600 mm

WHAT CAN WE DO FOR YOU?

We regard ourselves as a solution partner that assumes responsibility, supporting you from initial consultation and the planning phase right through to successful commissioning of the production line. We train your operating personnel, provide you with comprehensive technical documentation and continue to support you after commissioning with advice and practical help.

The Kallfass press consists of several press segments arranged one behind another. The torsion-resistant design and simple operability of the system ensure a high degree of functionality and process availability. Combined with quick-bonding adhesives and fully automated feeding / emptying, this enables the achievement of short cycle times and maximum production capacity.