Efficient and flexible

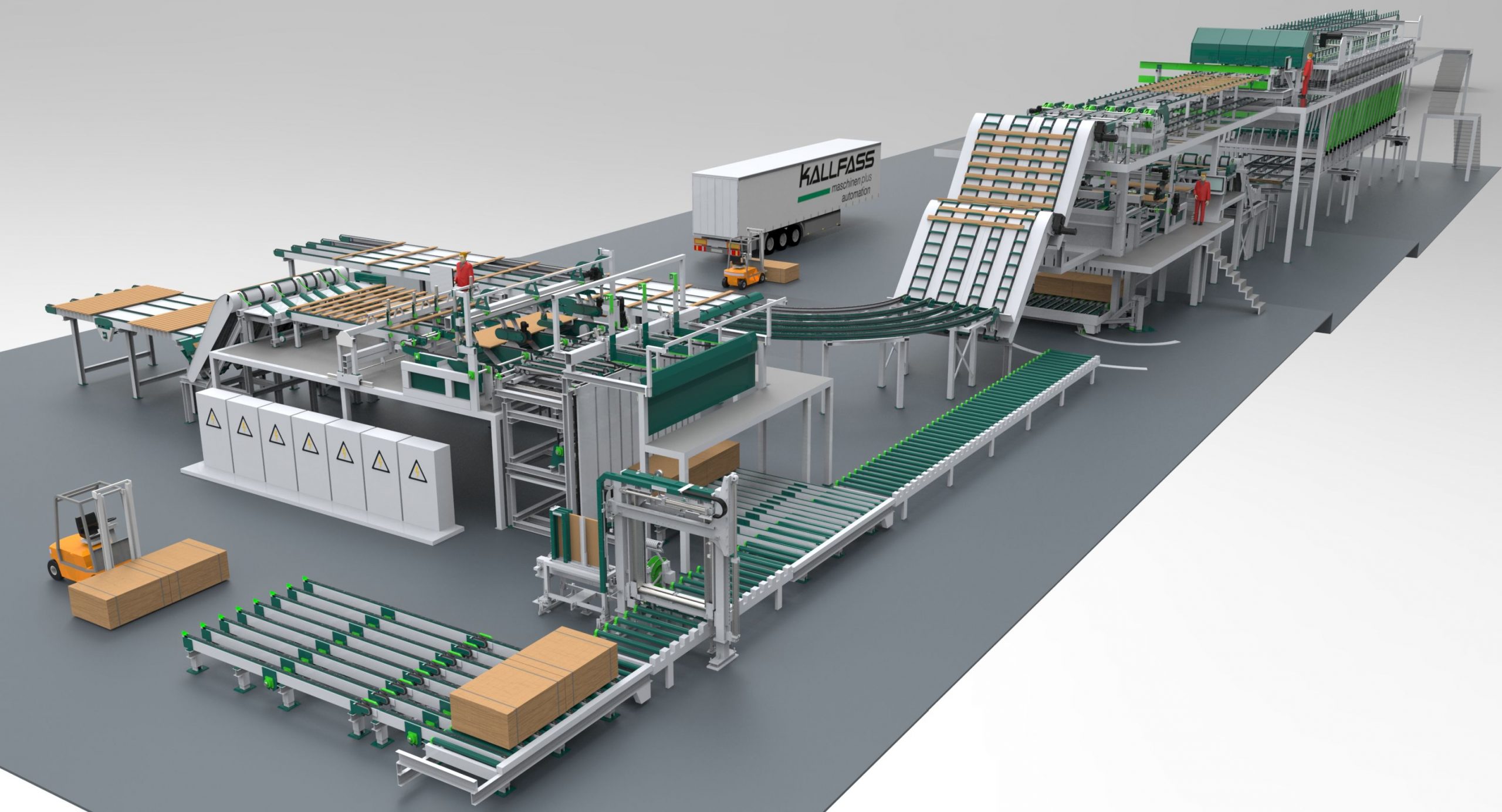

Box sorter

Timber classified according to dimensions and quality is sorted in sorting systems to achieve greater flexibility in production. Box sorters with inclined or vertical boxes are generally used.

Filling at a high cycle rate

INCLINED BOX SORTER

Inclined box sorters are generally used in high-performance productions, as they can be filled at a high cycle rate of up to 160 pieces/min. They ensure reliable emptying of material and are therefore recommended for sorting products with small and medium size material dimensions.

Sorting with a restricted space requirement

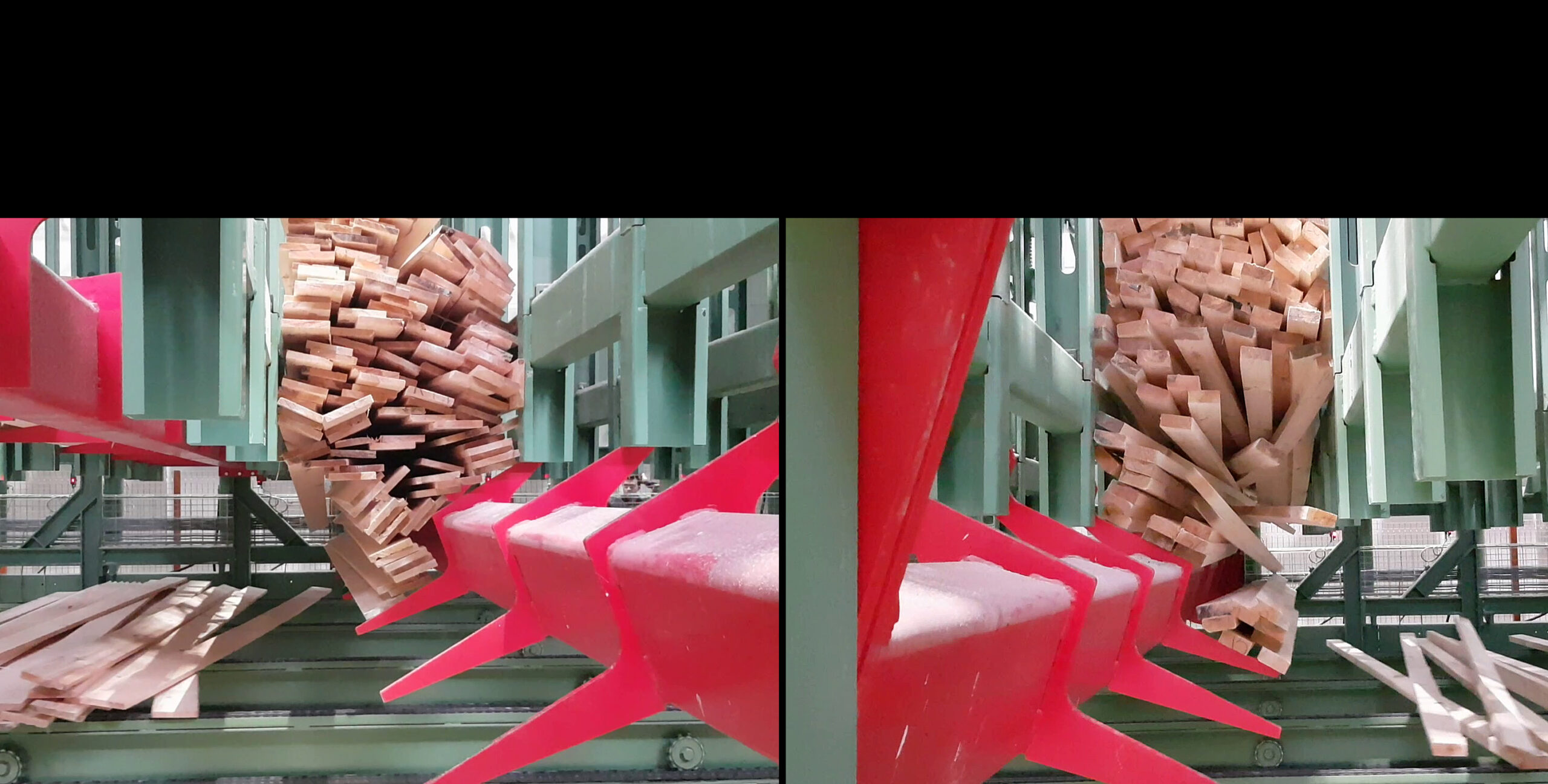

VERTICAL BOX SORTER

Use of a vertical box sorter can be sensible in confined space conditions, as vertical boxes need less space than inclined boxes and can accommodate more product boxes in the same area. Vertical boxes are mainly used for sorting side boards, as the box geometry makes emptying difficult and is not suitable for large material dimensions. The emptying direction can be suitably adapted to optimise the material flow. Vertical boxes are filled at a cycle rate of 120 pieces/min.

Timber product assortment

IDEAL VOLUME

The number of timber products determines the number of boxes. A box should ideally correspond to the volume of a stacked package, with the height of the boxes corresponding to the package cross section.

What can we do for you?

We regard ourselves as a solution partner that assumes responsibility, supporting you from initial consultation and the planning phase right through to successful commissioning of the production line. We train your operating personnel, provide you with comprehensive technical documentation and continue to support you after commissioning with advice and practical help.