Automation solution

Planing

We provide tailored, automated plant technology of the highest quality and combine individual processes to create an effective, high-performance planing unit with clever detail solutions.

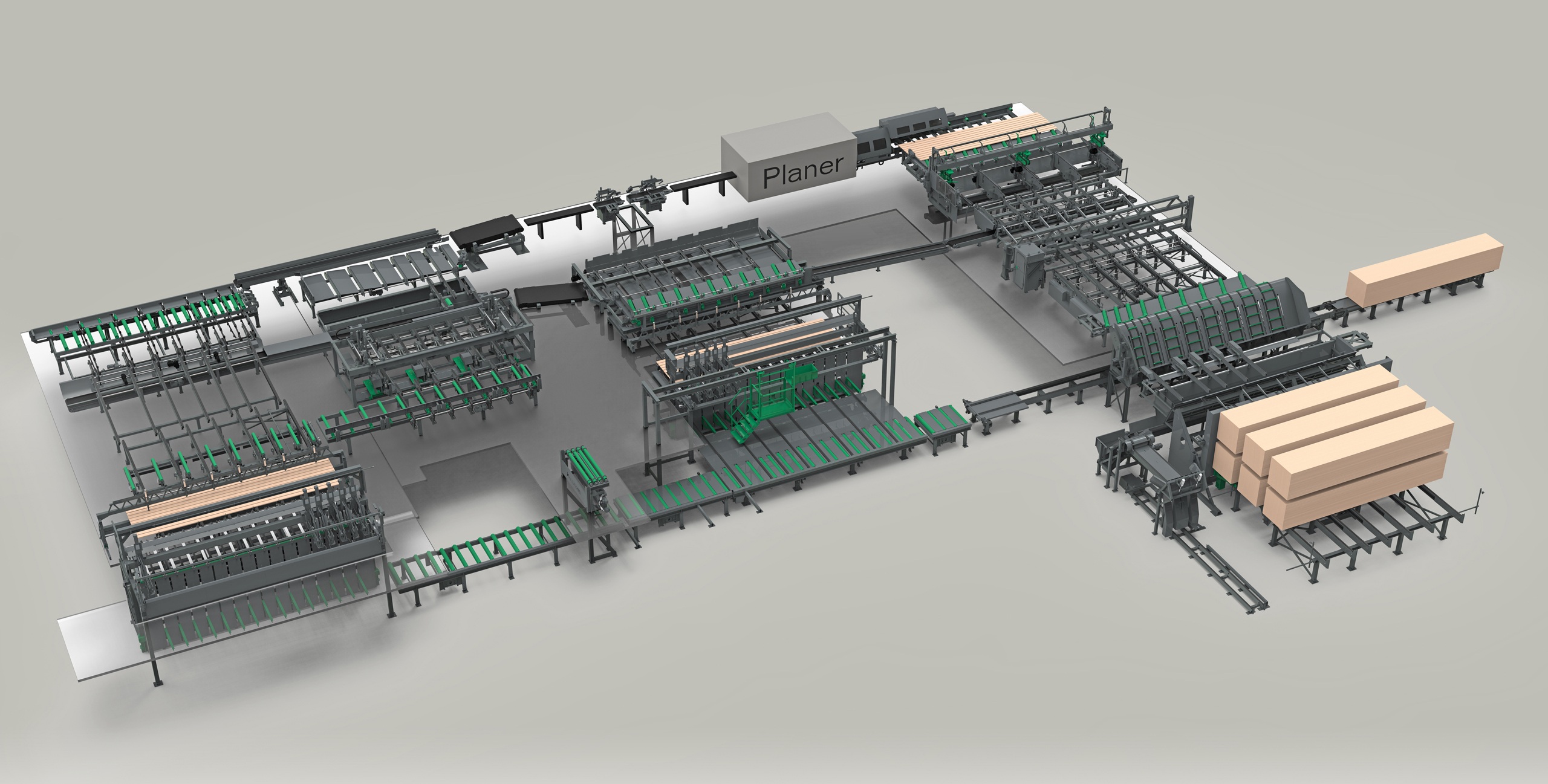

Installation example

Stick planing production line

Separation of single and multiple packages

High performance and a high cycle rate

TILT DESTACKING

For separating single and multiple packages with and without intermediate sticks upstream of planing and sorting systems. The packages are received in a transverse direction by a lifting unit, pivoted through approx. 45° and conveyed on to the skid edge. Layer by layer, the timber pieces now slid over a skid edge (which can be flexibly adjusted) to even out distortions in the layer.

Minimising setup times

TILT DESTACKING OF DOUBLE PACKAGES

Tilt destacking of double packages can halve setup times, minimising production costs as a result. The intermediate strips in double packages can be removed with the aid of a stick stripper (optional) and collected and sorted for further use or disposal.

Careful and gentle at a medium cycle rate

VACUUM DESTACKING

Vacuum suckers lift the topmost layer of a package and deposit it gently in a transverse direction on the conveyor. This careful handling is particularly suitable for avoiding surface damage to planed workpieces. The vacuum destacker is suitable for production lines with short to medium cycle rates.

Longitudinally and transversely at a low cycle rate

PUSH-OFF DESTACKING

This destacking involves pushing the uppermost layer of a package to the downstream process. Pushing can occur in a transverse or longitudinal direction, depending on the space requirement. This destacker is used on production lines with a low cycle rate.

Flexible and efficient

The ends of raw or planed timber workpieces are cut with millimetre accuracy to the desired fixed lengths in cross-cut saws. The workpieces can be processed individually or layer by layer. Powerful saw motors and feed speeds of max. 50 m/min ensure a high throughput.

Several cutting programs can be stored to ensure maximum production flexibility, or data can even be imported from ERP systems and master computers.

Continuity at high speed

Continuous material supply

FEEDING: Planing machines

Whether in layers or destacked, transverse or longitudinal, a continuous supply of timber is vital when feeding machining processes such as planing or sawing. Accelerating rollers ensure high feed speeds. The use of a slow-down belt is necessary as of a speed of 150m/min to decelerate the pieces after planing.

Greater stability during handling

BUNDLING: Sticks and boards

Bundling involves the joining of individual timbers to form a compact bundle. Bundles are easier to handle and have a greater degree of stability. This is a major advantage when, for example, stacking or during transportation. Between 8 and 11 bundles can be automatically strapped every minute, depending on the bundle dimension. A labelling option is available, either on individual boards or on the complete timber bundle.

Time-saving process solutions

Fully automatic material flow

STACKING: Shipping packages

Stacking of timber (including in multiple lengths) can be realised with placement forks or vacuum lifters, with the timber being collected in layers and deposited layer by layer on the shipping package to be formed. Dispatch strips can be laid between several layers to stabilise the shipping package. Strip laying is automatic. Where necessary, the shipping package is stabilised additionally through final strapping. Squared timbers can be optionally included on the package underside, and the packages can be pressed hydraulically together if desired. Customers who do not wish to have stabilising strips (e.g. because the package only needs to be transported within the company) may avail of offset stacking.

Effective air circulation, thanks to dry sticks

STACKING: Kiln packages

Wooden sticks are laid between each layer when stacking timber that is still damp in kiln packages. The intermediate sticks ensure adequate air circulation during drying and accelerate the drying process. The drying sticks are laid by stick magazines.

Option: Workpieces of different widths can also be stacked with spacing with the aid of a servo slide.

Reliable conveyor transfer

SINGLE FEED UNIT

The quality of individual boards cannot be assessed or measured without precise cycling in. Both the desired production speed and the homogeneity of the timber determine the cycling in process in this respect. With a consistent board thickness and production speed of maximum 80 cycles/min, individual boards are backed up and, using retaining pawls in combination with a plunger and acceleration conveyor, transferred individually to the next conveyor.

A soon as the thickness of the boards differs or higher production speeds are to be run, powerful TongLoader® units with a gripper system are used. Tong Loader® units can cycle in boards at a speed of up to 240 workpieces/min and are suitable for wet, dry and planed timbers.

Unambiguous classification

STRENGTH MEASUREMENT

Leading makes of multisensor scanner systems are used for strength sorting, measuring the timber precisely and classifying it at high production speeds pursuant to customer-specific quality requirements before it is forwarded on for planing, cutting to size or to sorting systems.

Consistent quality standard

MOISTURE MEASUREMENT

The water content of the timber is measured in mere seconds and without contact during moisture measurement. The analyser can be integrated at a flexible point in the production process. In the event of exceeding or undershooting the defined moisture level, the boards are marked behind the measuring head and rejected if necessary. Only timber that conforms to the desired classification is processed further, ensuring a consistently high quality standard.

Automated quality optimisation

WARP MEASUREMENT

Following drying, the degree of warping of a board is measured with the scanner system and the board turned over if necessary before further processing. This ensures an efficient, continuous process sequence.

Automatic positioning

STICK/BOARD MAGAZINES

During stacking, wood packages need to be dried or stabilised for shipping with intermediate sticks. Magazine are filled either manually or automatically with sticks or boards by robots for this purpose. Dual magazines can be fitted for a second stick size. Automatic stick placement is monitored by placement grippers.

Fully automatic stick handling

MAGAZINE FILLING WITH ROBOTS

Patented system!

Time-consuming filling of stick magazines in this variant is realised by a robot in a patented process that carries out charging at a constant cycle rate and almost without personnel. A stick scanner can be optionally used prior to magazine filling that assesses the quality of the sticks. Only suitable sticks are subsequently separated, packetised and then prepared for robot filling.

Interactive installation example

Solutions from a one-stop provider

We regard ourselves as a solution partner that assumes responsibility, supporting you from initial consultation and the planning phase right through to successful commissioning of the production line. We train your operating personnel, provide you with comprehensive technical documentation and continue to support you after commissioning with advice and practical help.

Separation of single and multiple packages

High performance and a high cycle rate

TILT DESTACKING

For separating single and multiple packages with and without intermediate sticks upstream of planing and sorting systems. The packages are received in a transverse direction by a lifting unit, pivoted through approx. 45° and conveyed on to the skid edge. Layer by layer, the timber pieces now slid over a skid edge (which can be flexibly adjusted) to even out distortions in the layer.

Minimising setup times

TILT DESTACKING OF DOUBLE PACKAGES

Tilt destacking of double packages can halve setup times, minimising production costs as a result. The intermediate strips in double packages can be removed with the aid of a stick stripper (optional) and collected and sorted for further use or disposal.

Careful and gentle at a medium cycle rate

VACUUM DESTACKING

Vacuum suckers lift the topmost layer of a package and deposit it gently in a transverse direction on the conveyor. This careful handling is particularly suitable for avoiding surface damage to planed workpieces. The vacuum destacker is suitable for production lines with short to medium cycle rates.

Longitudinally and transversely at a low cycle rate

PUSH-OFF DESTACKING

This destacking involves pushing the uppermost layer of a package to the downstream process. Pushing can occur in a transverse or longitudinal direction, depending on the space requirement. This destacker is used on production lines with a low cycle rate.

Flexible and efficient

The ends of raw or planed timber workpieces are cut with millimetre accuracy to the desired fixed lengths in cross-cut saws. The workpieces can be processed individually or layer by layer. Powerful saw motors and feed speeds of max. 50 m/min ensure a high throughput.

Several cutting programs can be stored to ensure maximum production flexibility, or data can even be imported from ERP systems and master computers.

Continuity at high speed

Continuous material supply

FEEDING: Planing machines

Whether in layers or destacked, transverse or longitudinal, a continuous supply of timber is vital when feeding machining processes such as planing or sawing. Accelerating rollers ensure high feed speeds. The use of a slow-down belt is necessary as of a speed of 150m/min to decelerate the pieces after planing.

Greater stability during handling

BUNDLING: Sticks and boards

Bundling involves the joining of individual timbers to form a compact bundle. Bundles are easier to handle and have a greater degree of stability. This is a major advantage when, for example, stacking or during transportation. Between 8 and 11 bundles can be automatically strapped every minute, depending on the bundle dimension. A labelling option is available, either on individual boards or on the complete timber bundle.

Time-saving process solutions

Fully automatic material flow

STACKING: Shipping packages

Stacking of timber (including in multiple lengths) can be realised with placement forks or vacuum lifters, with the timber being collected in layers and deposited layer by layer on the shipping package to be formed. Dispatch strips can be laid between several layers to stabilise the shipping package. Strip laying is automatic. Where necessary, the shipping package is stabilised additionally through final strapping. Squared timbers can be optionally included on the package underside, and the packages can be pressed hydraulically together if desired. Customers who do not wish to have stabilising strips (e.g. because the package only needs to be transported within the company) may avail of offset stacking.

Effective air circulation, thanks to dry sticks

STACKING: Kiln packages

Wooden sticks are laid between each layer when stacking timber that is still damp in kiln packages. The intermediate sticks ensure adequate air circulation during drying and accelerate the drying process. The drying sticks are laid by stick magazines.

Option: Workpieces of different widths can also be stacked with spacing with the aid of a servo slide.

Optional equipment

The added bonus for your success! This equipment allows you to enhance your product quality while simultaneously reducing changeover times and personnel costs.

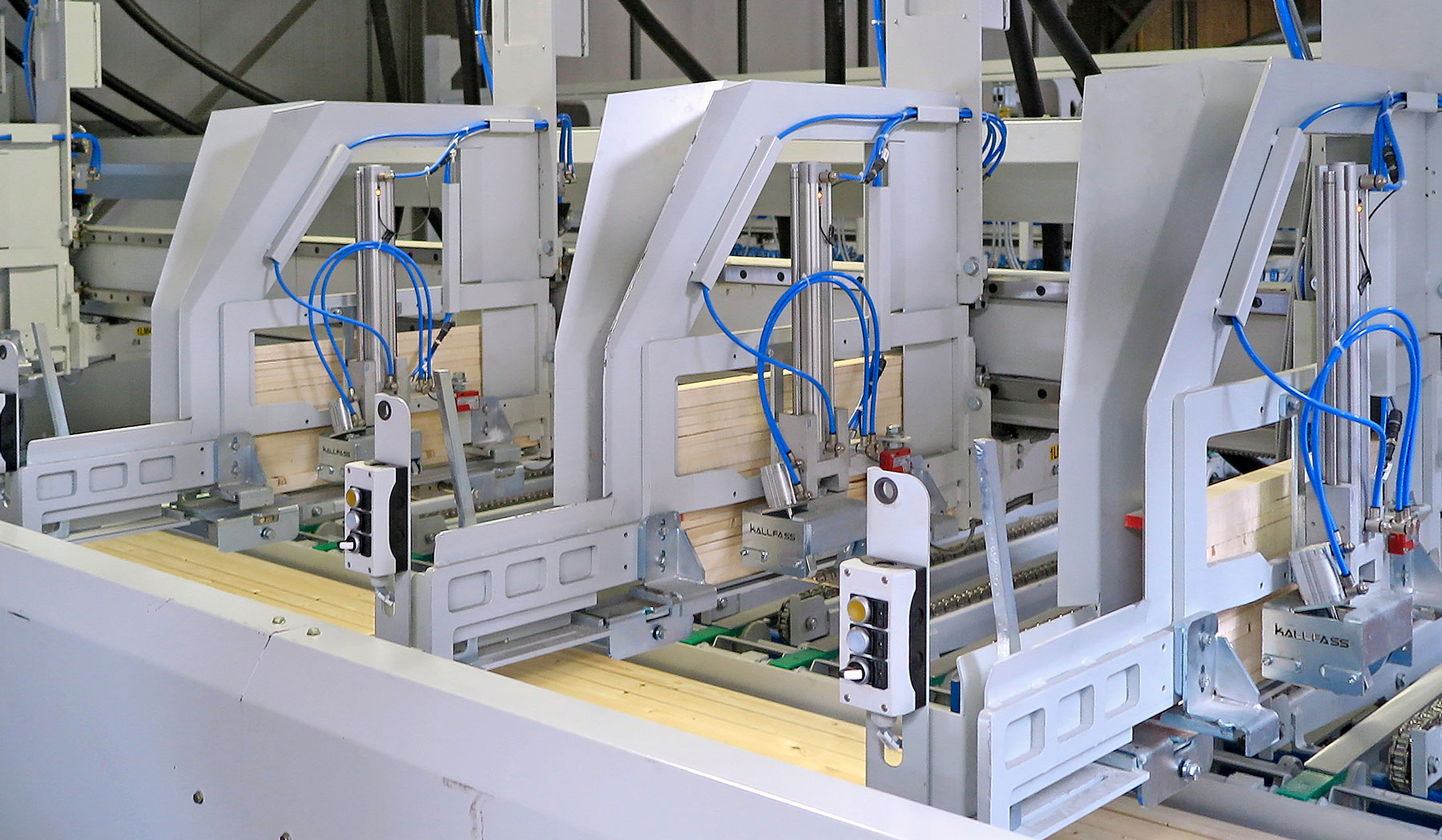

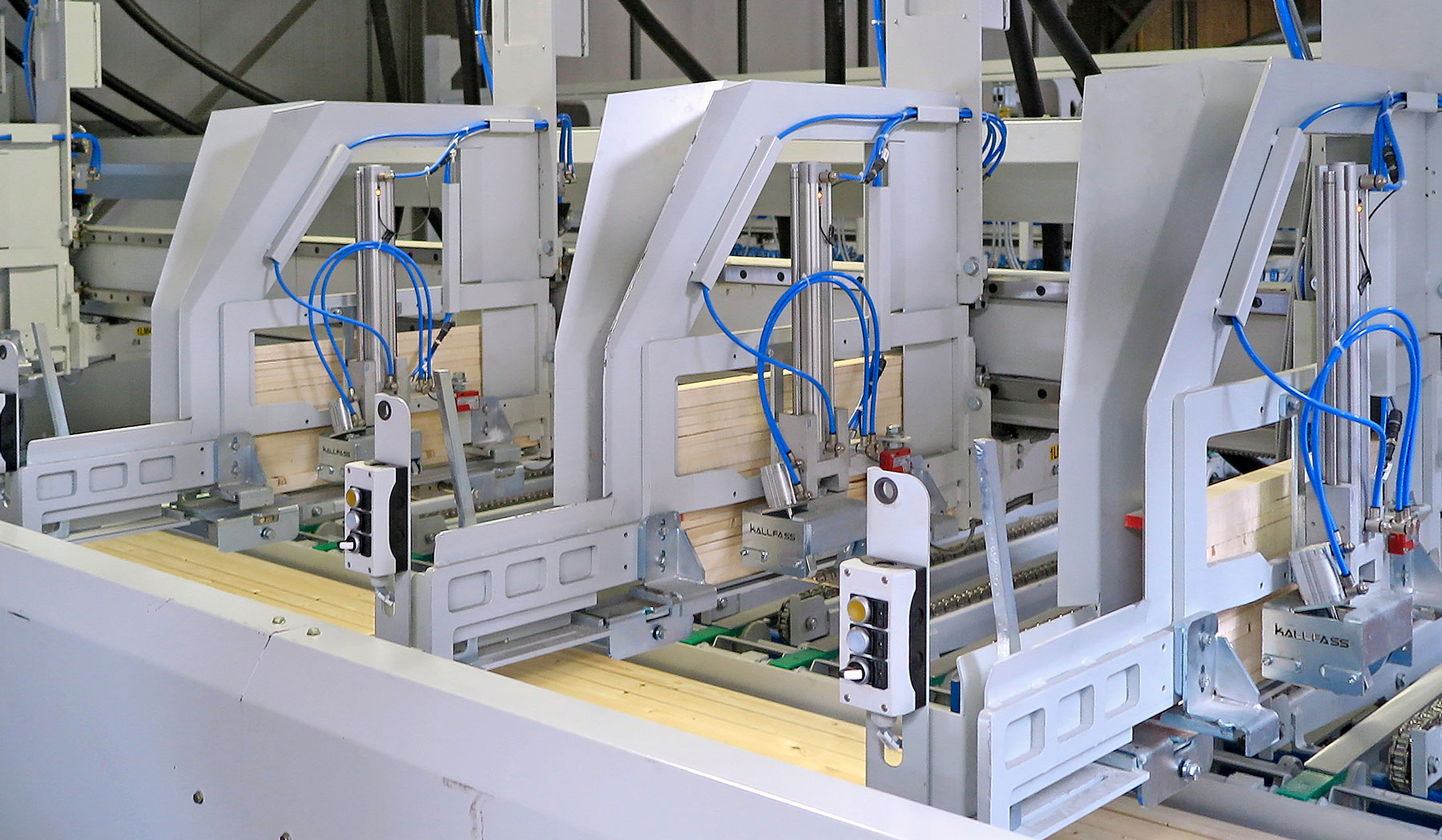

Reliable conveyor transfer

SINGLE FEED UNIT

The quality of individual boards cannot be assessed or measured without precise cycling in. Both the desired production speed and the homogeneity of the timber determine the cycling in process in this respect. With a consistent board thickness and production speed of maximum 80 cycles/min, individual boards are backed up and, using retaining pawls in combination with a plunger and acceleration conveyor, transferred individually to the next conveyor.

A soon as the thickness of the boards differs or higher production speeds are to be run, powerful TongLoader® units with a gripper system are used. Tong Loader® units can cycle in boards at a speed of up to 240 workpieces/min and are suitable for wet, dry and planed timbers.

Unambiguous classification

STRENGTH MEASUREMENT

Leading makes of multisensor scanner systems are used for strength sorting, measuring the timber precisely and classifying it at high production speeds pursuant to customer-specific quality requirements before it is forwarded on for planing, cutting to size or to sorting systems.

Consistent quality standard

MOISTURE MEASUREMENT

The water content of the timber is measured in mere seconds and without contact during moisture measurement. The analyser can be integrated at a flexible point in the production process. In the event of exceeding or undershooting the defined moisture level, the boards are marked behind the measuring head and rejected if necessary. Only timber that conforms to the desired classification is processed further, ensuring a consistently high quality standard.

Automated quality optimisation

WARP MEASUREMENT

Following drying, the degree of warping of a board is measured with the scanner system and the board turned over if necessary before further processing. This ensures an efficient, continuous process sequence.

Automatic positioning

STICK/BOARD MAGAZINES

During stacking, wood packages need to be dried or stabilised for shipping with intermediate sticks. Magazine are filled either manually or automatically with sticks or boards by robots for this purpose. Dual magazines can be fitted for a second stick size. Automatic stick placement is monitored by placement grippers.

Fully automatic stick handling

MAGAZINE FILLING WITH ROBOTS

Patented system!

Time-consuming filling of stick magazines in this variant is realised by a robot in a patented process that carries out charging at a constant cycle rate and almost without personnel. A stick scanner can be optionally used prior to magazine filling that assesses the quality of the sticks. Only suitable sticks are subsequently separated, packetised and then prepared for robot filling.