Machines and systems

for timber processing

We are a family enterprise that can look back over 75 years of experience in the manufacture of machinery and systems for timber processing. More than one hundred personnel are employed in the design and production of systems at our two locations in Klosterreichenbach (Baden-Württemberg) and Wernigerode (Saxony-Anhalt).

Our expertise is

the basis of success

A team of specialists

We support you right from the planning phase of your sawmilling project to achieve the best possible results. Our services include all steps such as planning, design, production, installation, programming and commissioning of the system we deliver.

Our solutions for the wood processing industry –

Individual & Functional

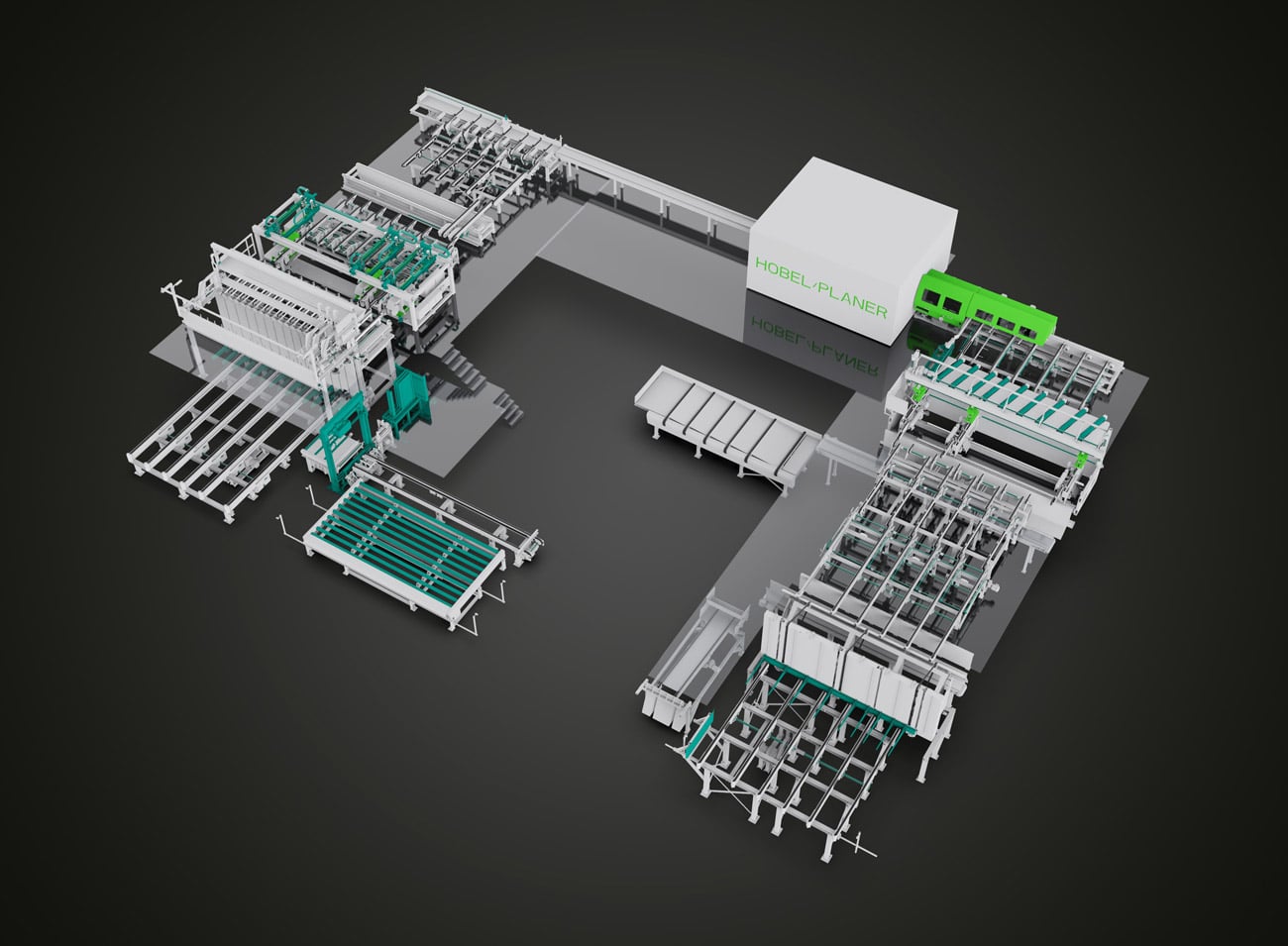

Kallfass successfully realises automation projects for global players in timber processing enterprises all over the world. The problems addressed are diverse, and our solutions are always individual.

- Automation solutions

- Cross-cut saws

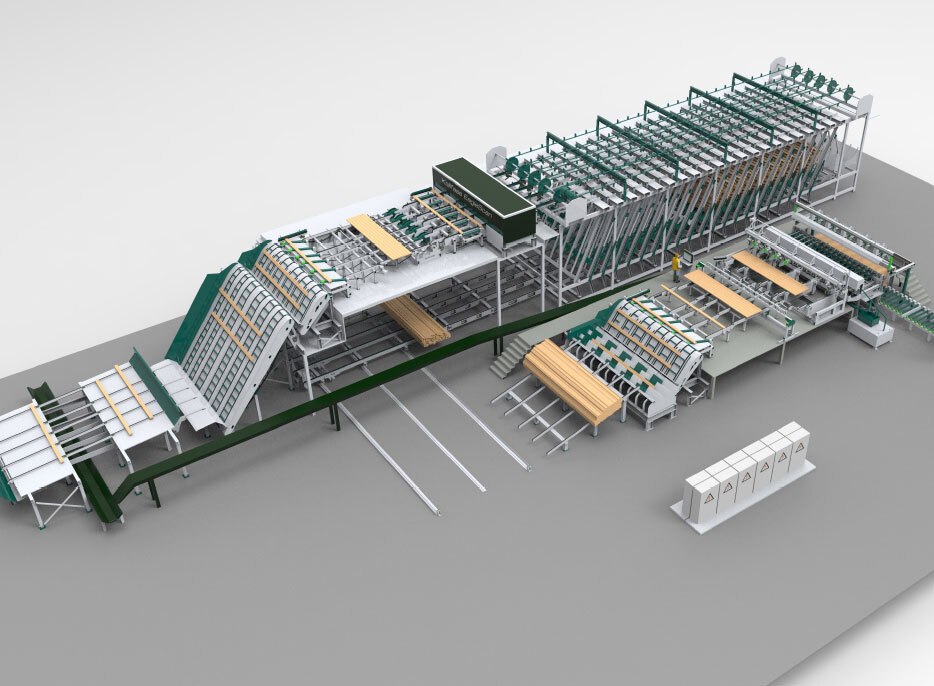

- Sorters

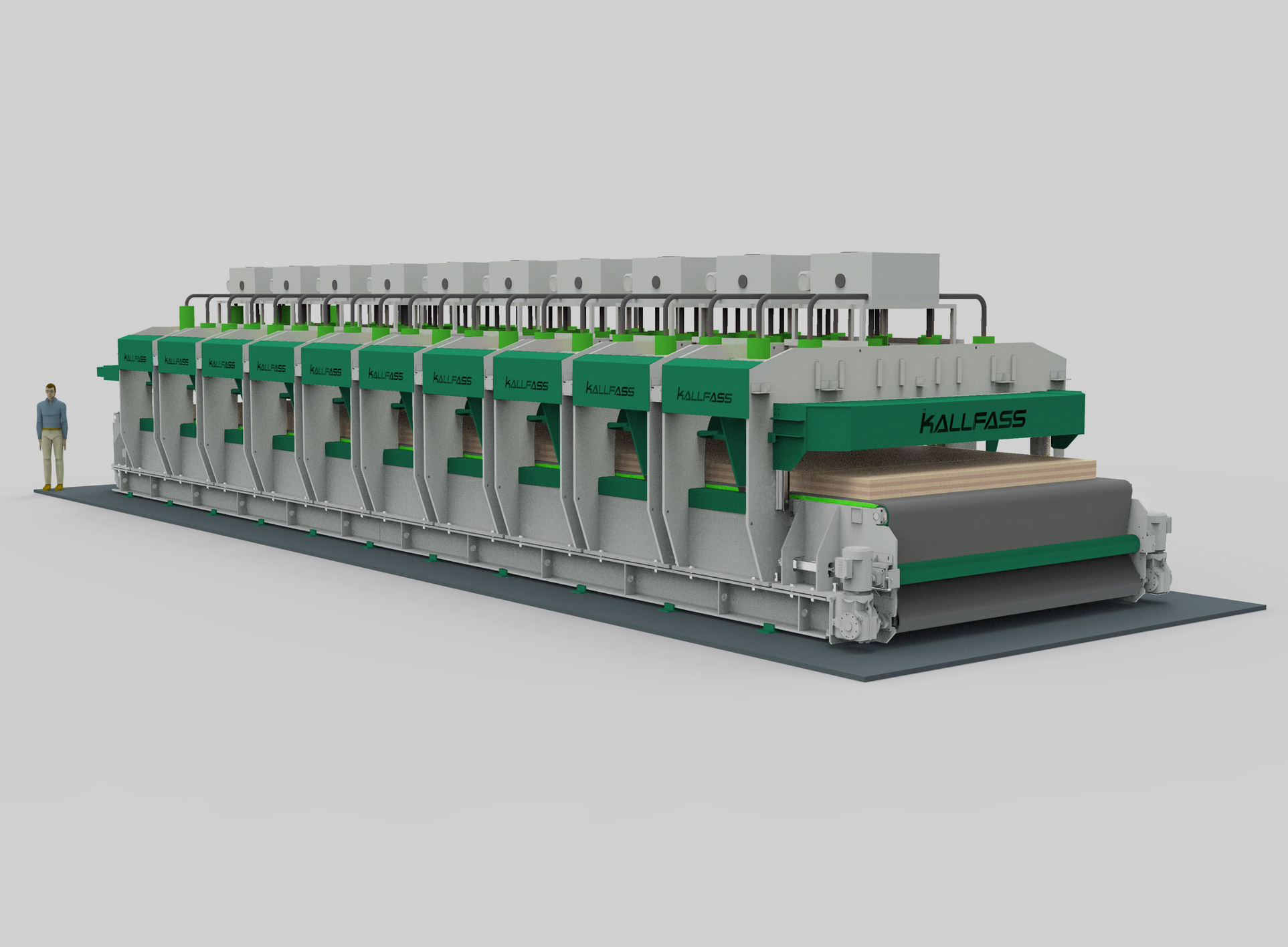

- Presses

Our focus with regard to all automation solutions is on a continuous material flow and high process efficiency of your system.

To the automation solutions

Our high-performance cross-cut saws can be flexibly configured and ensure that you enjoy maximum flexibility in production and achieve a maximum variety of products.

To the cross-cut saws

We integrate our efficient sorting solutions for classified timber as box or level sorters in your sawmill process.

To the sorters

Our CLT press combines single-layer boards with a length of 8 to 20 m to create multi-layer panels with a high degree of product precision.

To the presses

Kallfass worldwide projects

in the wood processing industry

Our References

Ein BSP-Werk für Profis EN A CLT plant for professionals

In the CLT plant at best wood Schneider in Meßkirch, Kallfass is responsible for...

read moreBis auf den letzten Millimeter ausgenutzt EN Utilised down to the last millimetre

In the new sorting and stacking plant at Åsljunga Pallen in Sweden, attention was...

read moreErstes gemeinsames Projekt erfolgreich abgewickelt EN The first joint project has been successfully completed

The new Kallfass restacking system at Robeta Holz has become a real reference project...

read moreNeue Stapellinie mit einer technischen Raffinesse EN New stacking line with technical sophistication

The new stacking line from Kallfass makes it possible to form sawn timber packages...

read more

New at Kallfass

Press

Positiver Messeverlauf EN Positive results from the

trade fair

Kallfass achieved a good response at the LIGNA fair and draws a positive conclusion.

read more

Press

Ausreichend Druck auf jedem Quadratmillimeter EN Adequate pressure on every square millimetre

Kallfass, has expanded its product portfolio for cross-laminated timber (CLT) production with its own CLT press and can now supply a complete mechanisation system, from the package pick-up to...

read more

Press

DER NORDSCHWARZWALD UND SEINE WELTMARKTFÜHRER EN The northern Black Forest and its global market leader

Kallfass helps its sawmill customers to implement innovative product ideas and achieve special production requirements in practice and develops tailored fully automated process and plant technology.

read moreOur recipe for success

and your future

Kallfass Newsletter

Don't

miss

out!

We’ll keep you up to date.

Our newsletter service provides you with all the latest information on our products, further devel-opments, trade show appearances and our company, simply and absolutely free.