In May 2022, Cordes Holz of Bremerhaven, Germany, started a new planing line. The company relies on the expertise of Kallfass, Baiersbronn, Germany, for the line’s automation. In fact, skill was in high demand: The planing line is highly flexible, increasing its complexity simultaneously.

The distinctive feature of the planing line and quality sorting line starts with the package feed. In order to achieve this, Kallfass used a two-level design. “At the lower level, the packages are transported in a straight line, moving towards the laminated timber production system. A long roller conveyor moves the wood from the upper level to the tilt destacker”, explains Enrico Goldhahn, Kallfass’ Project Manager. The packages are separated in layers, and the stacking strips are automatically collected. During the transport, the boards are guided to a pre-separator which then passes the boards on to the unscrambler. A thickness measurement device is integrated into the latter. If two pieces of wood are placed on top of each other, both pieces are ejected and returned to the unscrambling trough. The aim is to keep all manual operations as low as possible. After alignment at the zero line, a TongLoader® unit separates the board film. Goldhahn puts the TongLoader’s® output at a maximum of 80 boards per minute.

All measurements are taken during the transverse run-through

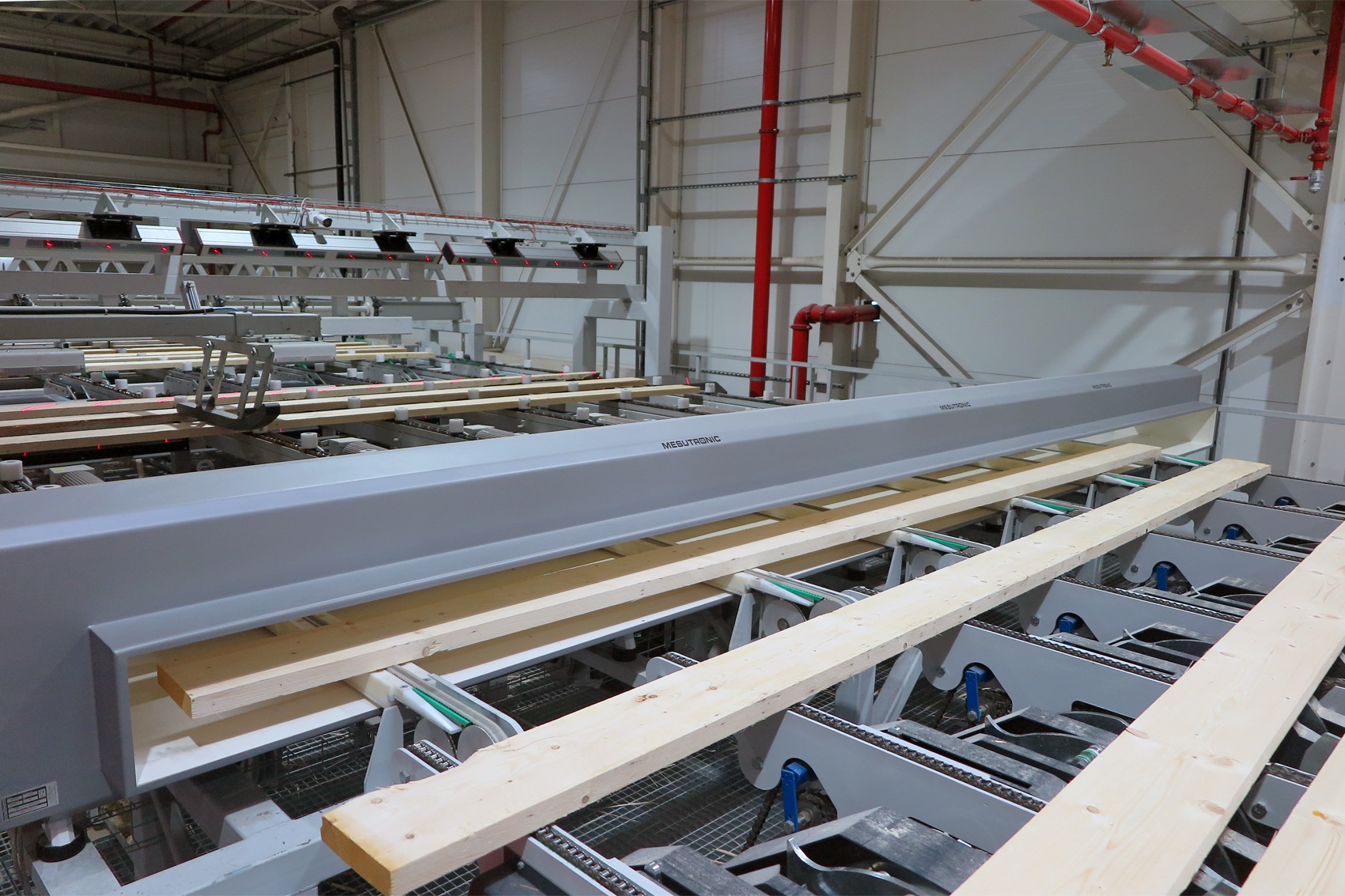

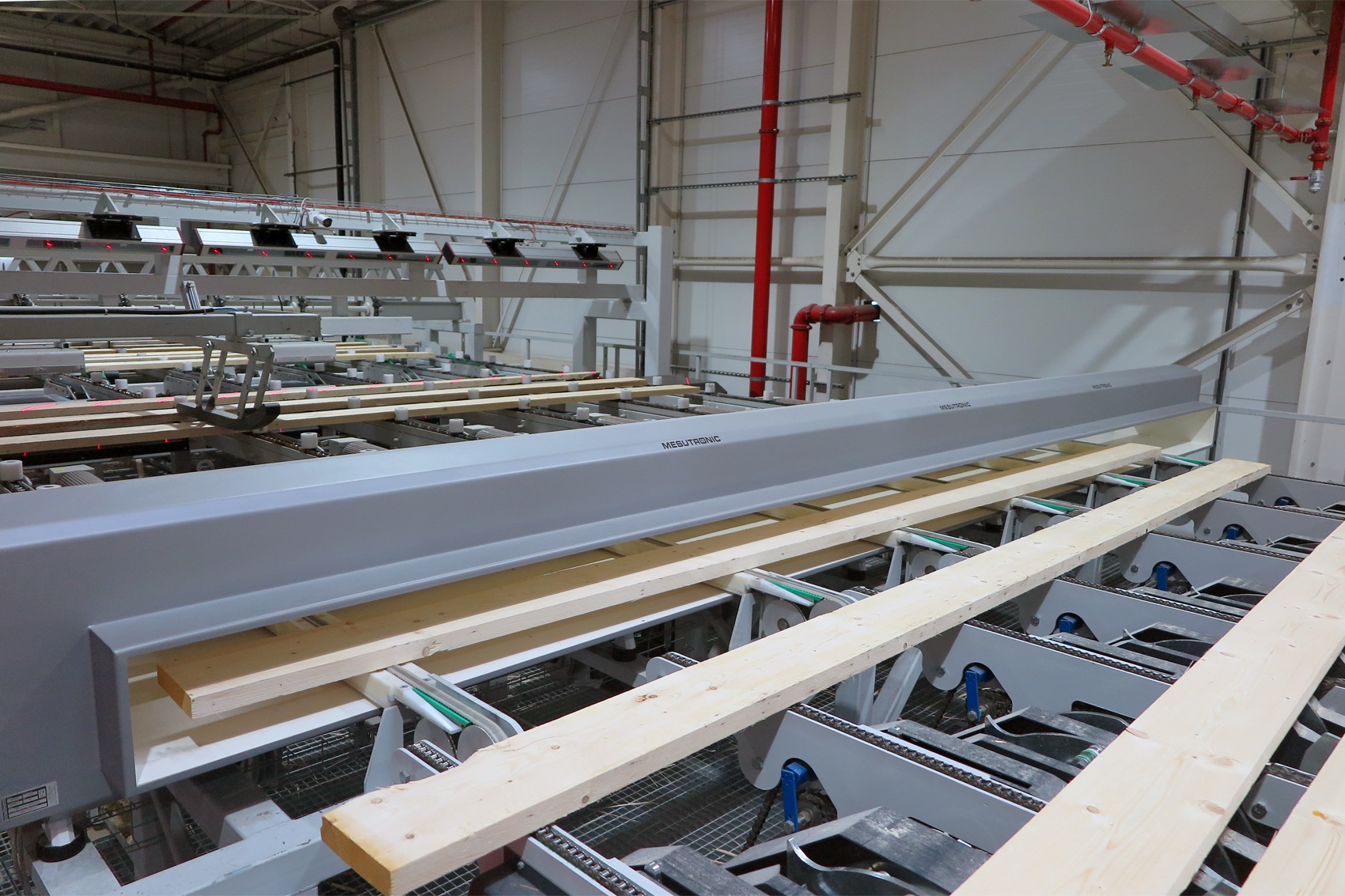

While the lumber follows the transverse run-through, it also passes the Mesutronic metal detector and a face cutter, which prepares the lumber for the subsequent strength measurement process. Microtec also supplied the M3 Scan moisture meter, the Optiside cup scanner and annual ring detection system, the Curvescan 3D board shape scanner, and the Viscan strength grader. All measurements take place during the run-through process. The Optiside scanner transmits a signal to the downstream Kallfass turning device, prompting it to rotate the lumber. Workpieces that do not meet the specified criteria are rejected.

Mesutronic metal detector

Planing or quality sorting

At this point, the paths diverge: If a pure quality sorting operation is selected, a bypass is used to convey the good lumber past and beyond the REX planing machine at a speed of up to 400 m/min.

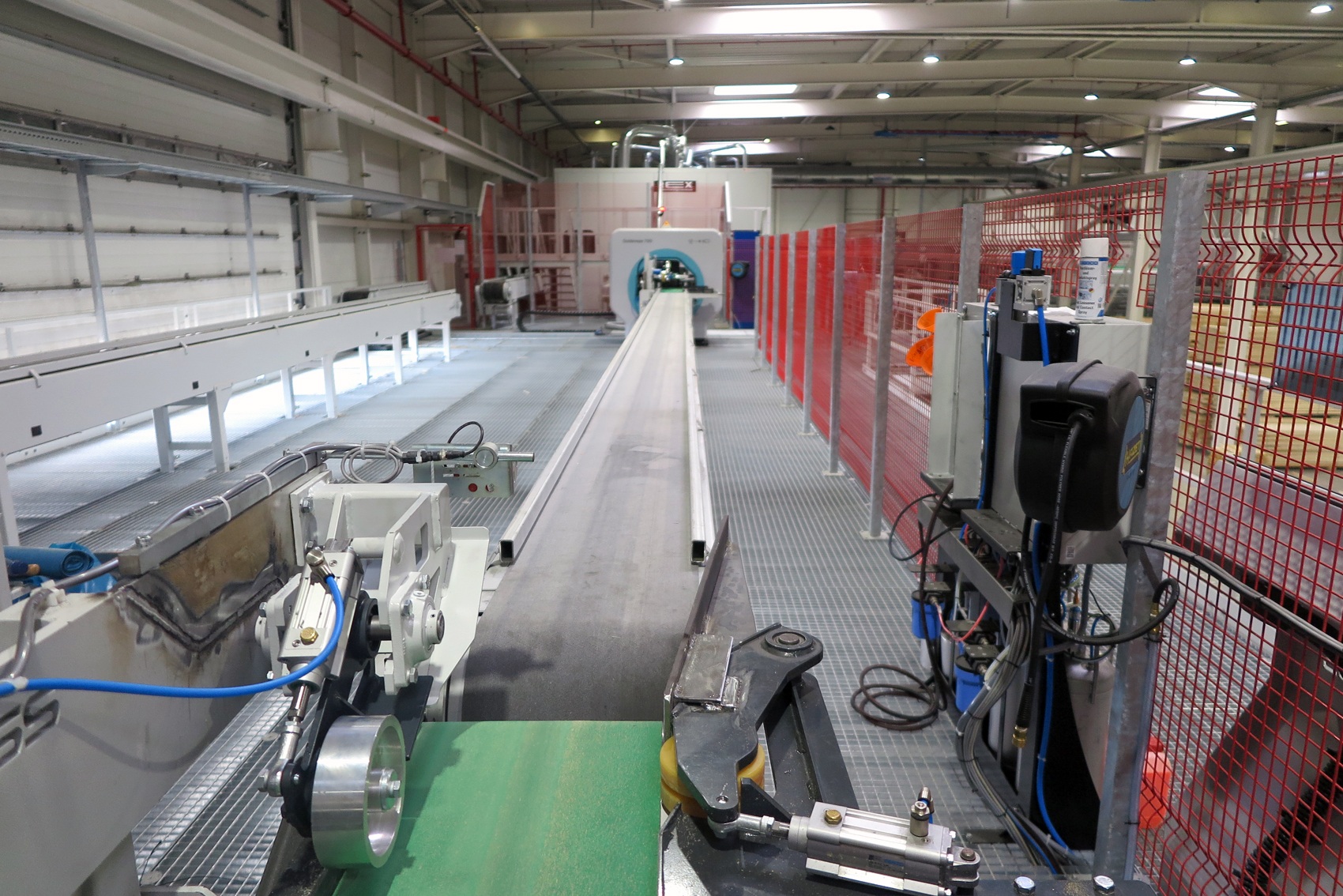

Variant 2: The good parts requiring planing are fed into the Kallfass planing machine, where an acceleration conveyor optimises the infeed of the timber. Goldhahn indicates that the intake system can reach up to 80 cycles per minute. The feed speed of the planing system can reach up to 350 m/min. Behind the planer, a conveyor belt advances the boards to the Microtec Goldeneye. The entire intake, scanning, and outfeed areas can be shifted to the left out of the planing line or to the right into the bypass line. If scanning is not selected, a motor pushes a bypass belt into the line instead of the scanner. After scanning, the parts move into the marking station, which can also be pushed into the line. Slowdown belts transfer the parts to the roof-top chain conveyor. “Here, the parts can come either from the bypass or the planing line – never from both lines at the same time”, Goldhahn explains.

At the sorting station, an operator arranges the boards according to three quality levels. He advances the pieces manually—one piece at a time—onto the assessment chain conveyor. A ram infeed unit transfers the goods (80 pieces per minute) to the infeed conveyor of the level sorting unit. In this area, the widths and thickness are measured. In addition, three Lumi scanners read the applied marking and the control system compares the marking with the scan result. After that, they part ways again.

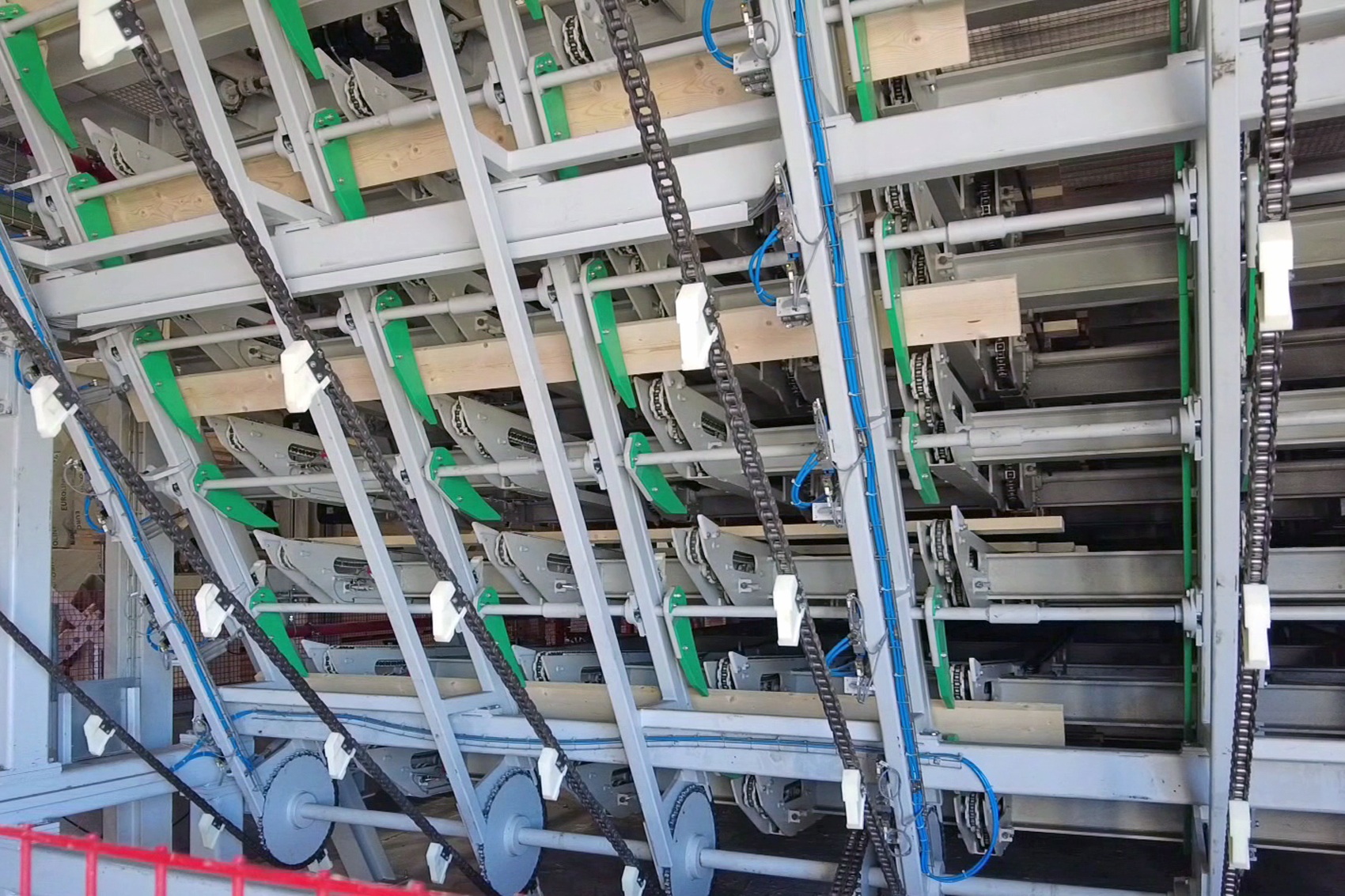

Kallfass level sorter

Bundling systems at a height of 6 m above the level sorter

Only workpieces that have been split in the planing machine and are narrower than 70 mm, as well as profiled boards, enter the Kallfass bundling system. The latter is installed 6 m above the level sorting unit. The sticks are labelled on an ascending belt conveyor before an aligning roller conveyor adjusts the sticks at the zero line. A motor-driven, height-adjustable gantry for applying labels is fitted with two labelling devices. Kallfass automatically assembles the sticks into bundles and straps them together. “We delivered six bundling units—so there is less adjusting required”, explains Goldhahn. Another labelling unit for the finished bundles is installed in the outfeed area.

All other boards enter one of Kallfass' six sorting levels. “Depending on the dimension, a package may have to be separated and placed on two levels. Because of the existing structural constraints, we had to proceed with this option”, Goldhahn explains. A pivoting conveyor is used to empty the individual levels. These boards are labelled as they pass through the production line.

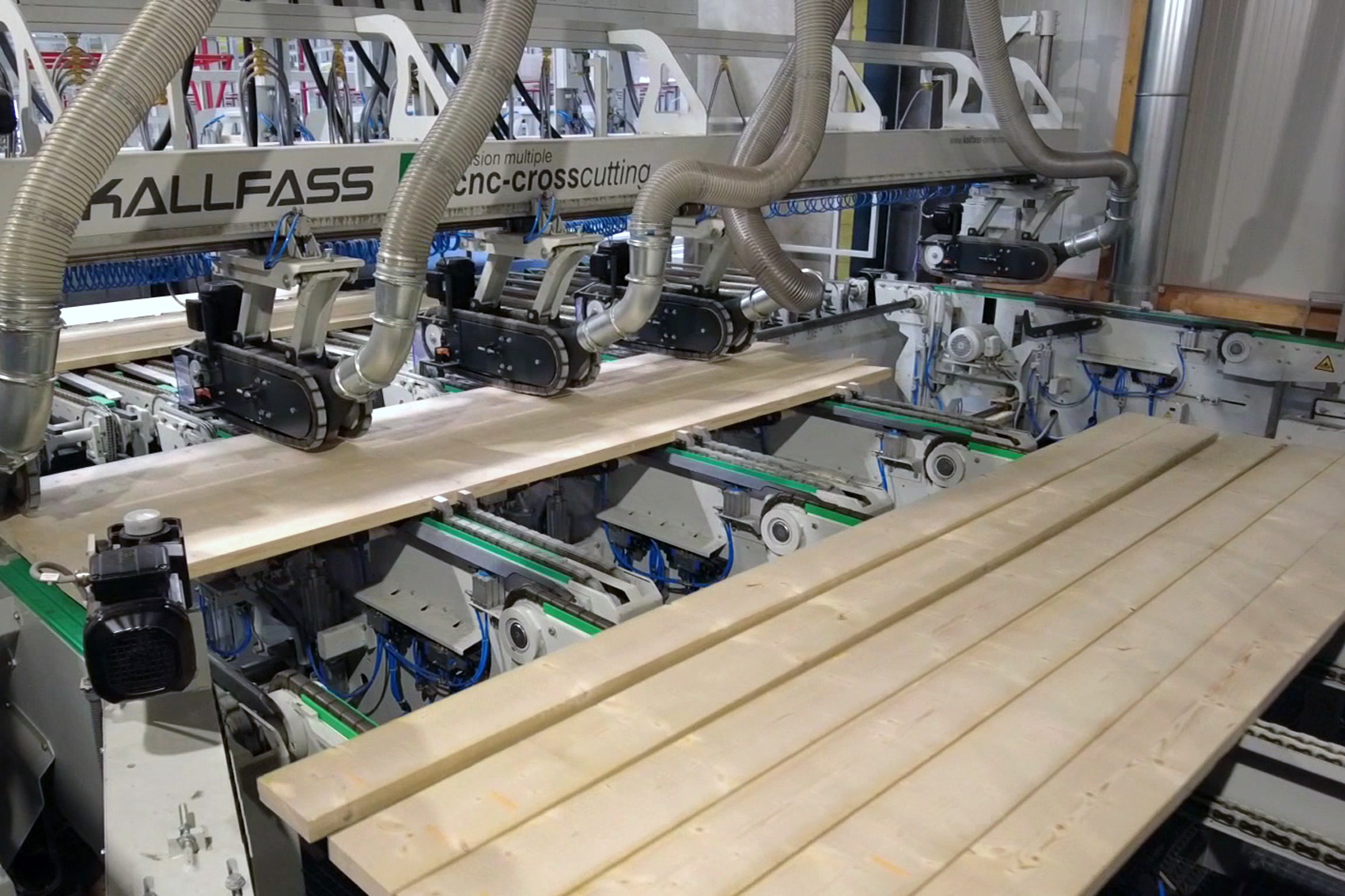

Once the filling level has been reached, the levels are emptied, and the layers are formed. The boards pass through the Kallfass multiple cross-cut saw with five sawing units. The shortest cutting length is 800 mm. “The pivoting saws are equipped with tandem cylinders. This allows us to vary the cutting height up to 160 mm. In addition, the zero saw can be adjusted by 500 mm”, explains Kallfass’ project manager.

Subsequently, the stacking takes place. The machine is equipped with eight stick magazines. In order to achieve greater stability for the ongoing transport, the Kallfass system can also stack the boards diagonally. For lower packages, an auxiliary hoisting unit with swivel forks increases the capacity.

The wood packages intended for the subsequent production of glue-laminated timber are fed directly into this production area using a roller conveyor. A forklift truck can be used to remove packages halfway along the line. At the end of the roller conveyor, an automatic crane made by Voith automatically removes the packages. Shipping packages are moved to the right-hand side and below the stacker. Here, a height-adjustable film dispenser automatically places the film on the stack first. The Kallfass mechanical system transfers the stack to the strapping unit, which includes a packaging press and applies four edge protectors to the stack. Squared timbers are then placed on the package. The roller conveyor is partitioned into three sections so that strapping and placing the squared timber can take place simultaneously. Finally, the wood packages can be stacked by the downstream stacker. “As an alternative to foil wrapping or strapping, there is a bypass that is integrated inside a foiling tunnel. In order to use this option, the packages are deflected to the left-hand side downstream of the stacker”, explains Goldhahn.

The Kallfass bundling station, 6 m above the level sorter

This is the third installation

Kallfass already delivered a smaller planing line for Cordes in 2018, which was completely rebuilt in 2020 and upgraded in order to include a bundling system. The assembly of the large-scale project described here started in 2021. Since 2022, the processes have been gradually improved and optimised. “We delivered approximately 65 lorries containing system components to Bremerhaven in order to construct the new quality-sorting and planing facility”, says Goldhahn, describing the overall scale of the project. The system can process lengths ranging from 2 to 6.2 m, widths of 75 to 310 mm and 16 to 125 mm thicknesses.

Starting the Kallfass system: Package infeed and subsequent tilt destacking

Downstream of the TongLoader®, an employee assesses the product...

…before it passes through the Mesutronic metal detector

Kallfass intake into the planing machine; capacity: up to 80 cycles a minute

View of the Microtec Goldeneye and the Rex planing machine

The Kallfass bundling station, 6 m above the level sorter

Tried and tested: The multiple cross-cut saw made by Kallfass