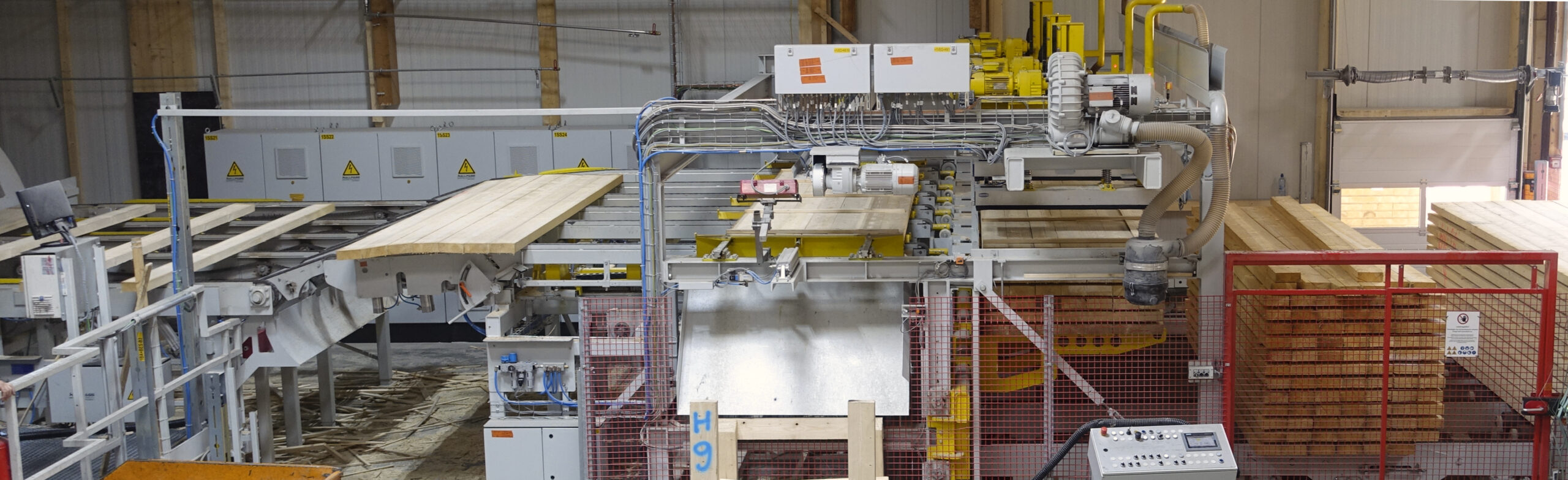

From S10 to KVH structural timber – planing, marking, labelling, bundling, foil wrapping, stacking of everything at up to 200 m/min

The extraordinary business success of Cordes Holz in Bremerhaven has compelled it to upgrade the planing unit after only two years. The plant was developed, expanded and modernised, and the result is a completely new Kallfass planing mill.

Kallfass had started the planing unit at Cordes Holz at the turn of the year 2018/2019. At that time, the line was, in essence, explicitly designed for DIY store products all over Europe. “The plant was extremely robust and very quick. In fact, it went so well that, despite our complete satisfaction, we were obliged to order an upgrade of the machine from Kallfass two years later”, explains Andreas Cordes, the owner. His primary wish was to enhance the level of flexibility with regard to dimensioning. And, while they were at it, they could also expand the marking options and, once again, increase the performance of the planing machine.

“The success of the machine forced us to upgrade after only two years”

Andreas Cordes

Takes on everything up to 290 mm and 6 m in length

What emerged was a universal plant that can do everything “from an S10 batten to raw solid structural timber, and from rhombic sections to square planing”, as Cordes describes it. That is considerably more products than could previously be manufactured. The maximum cross section is 290 mm by 165 mm and length of 6 m. Output was increased, despite comprehensive marking, labelling, foil wrapping, bundling and stacking options. The mechanisation is so powerful that the Rex Bigmaster could be enhanced from 100 to 200 m/min. The planing unit was designed for smaller solid structural timber cross sections, but it can now reach twice the speed and handle a much broader dimensional spectrum.

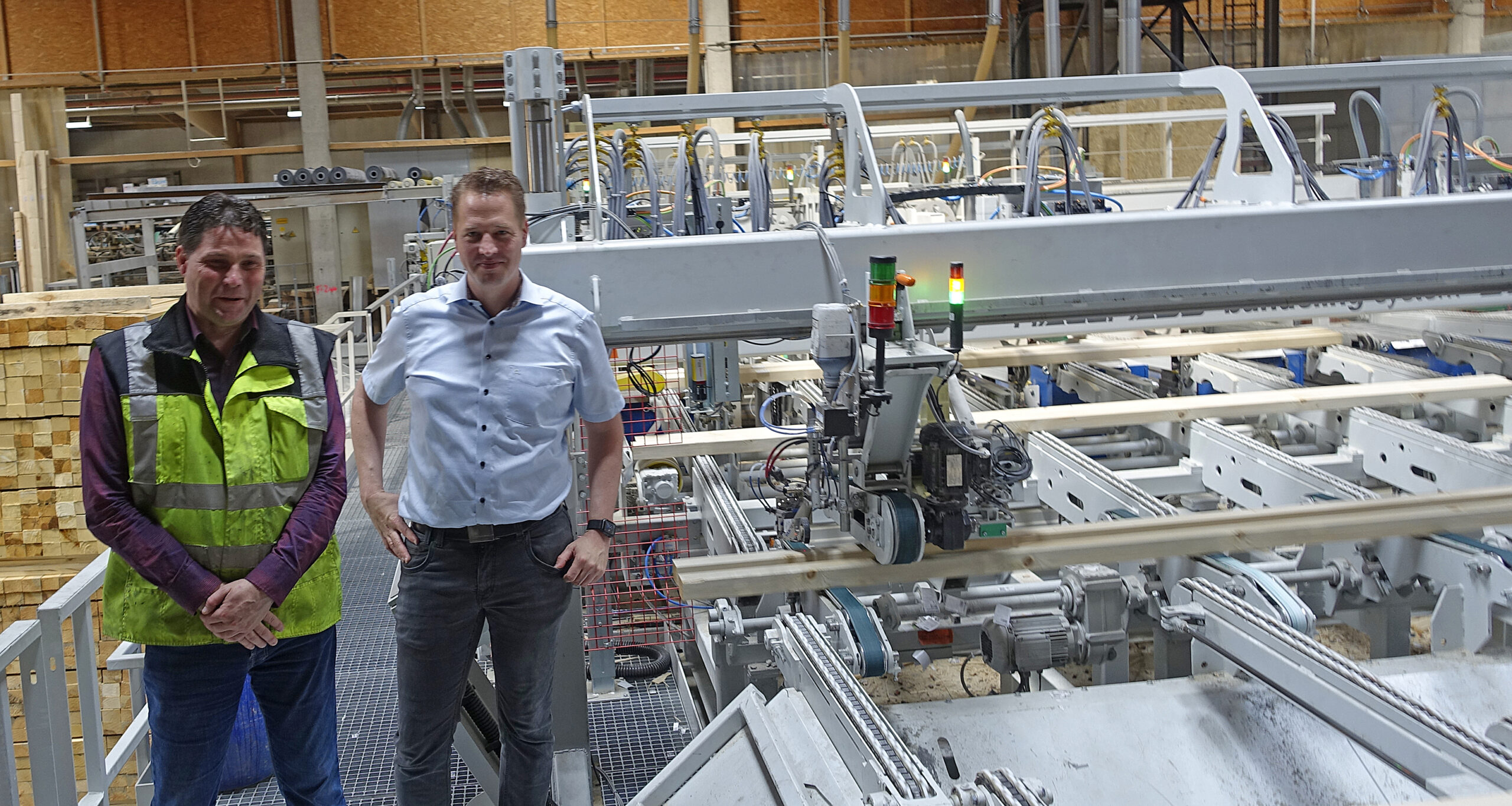

22 fitters for “open-heart surgery”

Kallfass realised the conversion during continuing operation. Up to 22 fitters were required to ensure that the general reconstruction could be achieved within ten weeks with only a single brief shutdown. “Actually, everything was changed, with the plant being expanded in three directions, and a lot of scanners, sensors and marking units were added”, explains Kallfass Project Manager Enrico Goldhahn. “It was open-heart surgery, and we performed it by working in two shifts, including over the weekend. We’re proud that, in spite of all the changes, hardly any stoppage occurred”.

There is a lot going on at the planing facility entrance: layer by layer separation, stick discharge, stick scanner, dimension check and feeding into the Bigmaster

Joint concept

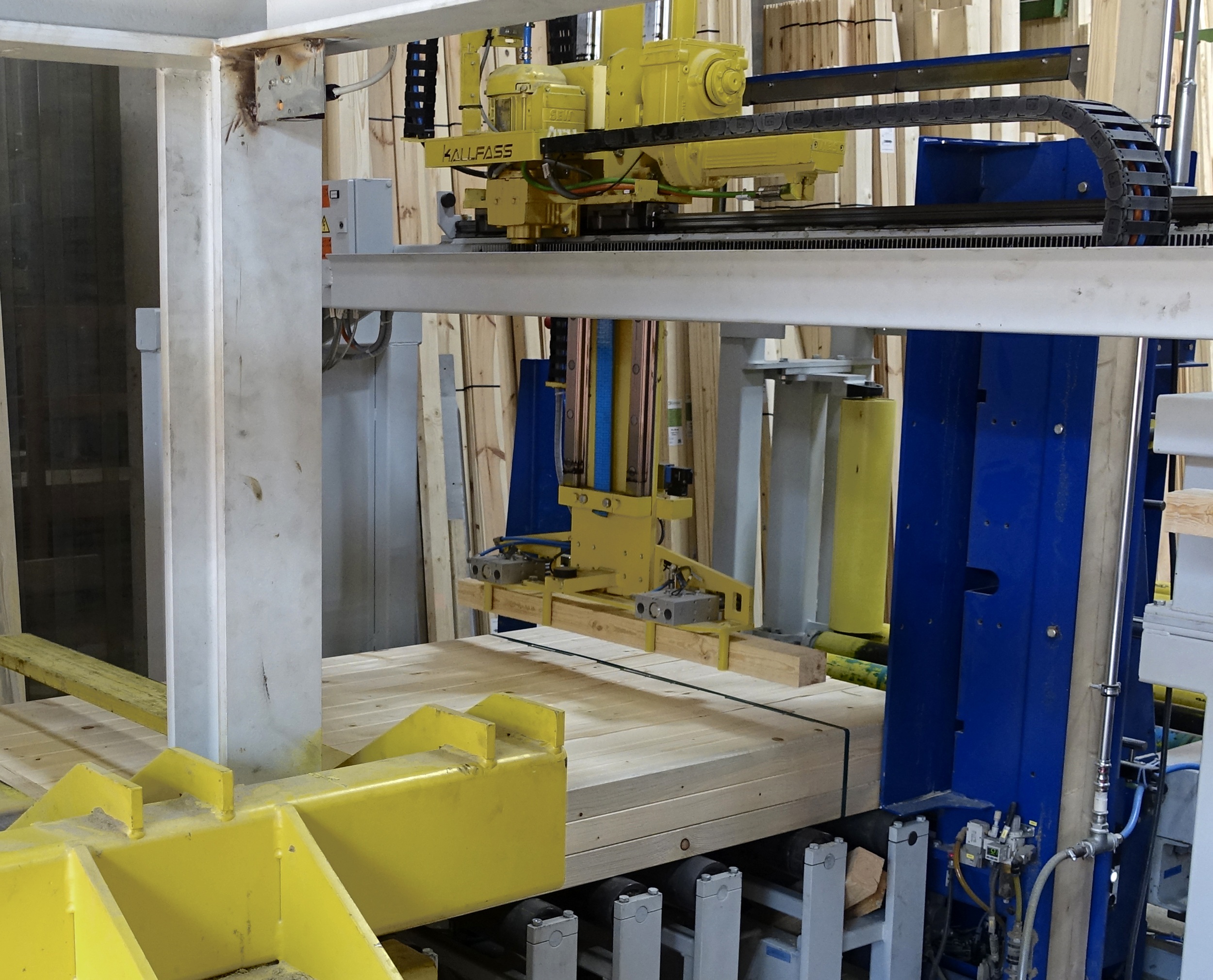

“The plant, as it now exists, was a joint development undertaken by REA Jet, Cordes and us”, says Goldhahn. Among other things, he recommended that a buffer conveyor be installed upstream of the destacking device. The plant picks up an uninterrupted stream of packages for vacuum destacking. “We suggested here that a vacuum destacker with a hoisting unit, stick stripper and ATB stick scanner be selected, and that’s exactly how it was constructed”, relates Goldhahn.

At Cordes, timbers that are too short or unsuitable can be separated upstream of the planing unit. “It’s not unusual for a short piece to be delivered with a package, but I can do without that in the planing mill”, explains Cordes, which is also why a warping meter from ATB in Roggenburg, Germany and a turning device were installed here.

Powerful, despite many processing options and cutting

The first REA Jet labelling run then followed, printing all the required information on the DIY products. The downstream multiple cross-cut saw is from Kallfass. “We can now trim with millimetre accuracy. From 800 mm short timbers to 6 m excess lengths – that means we’re extremely flexible”, says Cordes with delight during the tour of the new planing mill.

He can also call up the plant performance data live on his mobile phone. During the on-site visit of the Holzkurier, a 4m DIY package was completed every 50 seconds.

Foil wrapping, strapping, packet note – everything compact

Six strapping units for small and large pieces

“We delivered the first plant to Cordes with six strapping machines for bundling small and large pieces”, continues Goldhahn. Finally, the packages can also be wrapped in foil. Kallfass also provided an offsetting station for quart packages. The stacking system can handle both small and large packages up to a package height of 2.4 m. “The automatic squared timber stacking is accelerated further, making everything perfect”, says Goldhahn, explaining the success.

Only two operators for the plant

Only two employees work in the plant on each shift. The team monitors the process and ensures that material such as labelling rolls is filled. Just how well the two work together became apparent during the visit. One of them focuses on feeding timber pieces up to the rear of the planing machine. A fault must be remedied here in the case of broken raw timber, or labelling rolls inserted. The second man stands beside the package assembly system. Bearers (squared timbers) or sticks are refilled there.

Praise from the biggest name in Germany

If Andreas Cordes accepts the plant by saying “We’re very satisfied”, his words carry weight. This is the judgement of a man whose corporate group includes German planing specialists such as Osmo Holz in Warendorf, Holz-Henkel in Göttingen and Krages Holzindustrie in Hamburg. In addition, Rettenmeier, a subsidiary, also creates planed workpieces at several locations. This means that the Cordes Group probably has the greatest planing capacity in Germany.

Cordes still has major plans for Bremerhaven. Solid structural timber will be increased to 200,000 m³ per annum, along with an additional 50,000 m³ a year of glued laminated timber. Kallfass is a significant partner for deliveries of these systems. A test run should commence this year.

Three stacks wait in front of the facility, with timber fed in automatically

Enrico Goldhahn and Andreas Cordes (from left): The Kallfass project manager and the Cordes Group owner

Enhanced planing unit: the Rex Bigmaster now runs at up to 200 m/min

Marking at full speed: units supplied by REA Jet

Trimming with millimetre accuracy, whether 80 cm short timbers or 290 mm solid structural timbers

Automatic package squared timber stacking

Text and images: Gerd Ebner, Holzkurier

Holzkurier 26/2021