Three years ago, the Lemaire sawmill decided to invest in another sawmill for small diameter timber. This means that the entire log spectrum can now be processed. Kallfass was chosen for the sorting and stacking plant, as the mechanisation specialist impressed in many respects.

After a fire in 2020 at the headquarters in Moussey/FR, the owners of the Lemaire sawmill decided to rebuild the line with a log band saw while investing in a new sawmill for cutting small diameter timber at the La Petite-Raon site a few kilometres away. "This step means we can process the entire log spectrum from the forest", says Managing Director Maxence Lemaire, explaining the move. They bought an industrial site in La Petite-Raon in 2006 which they previously used for sorting logs and operation of a planing unit. Installation of the saw line began two years ago. The sawmill was to be initially housed in the existing hall. However, the Lemaire family eventually decided to erect a new building. The log infeed came from Holtec, the cutting line was supplied by Veisto and Kallfass from Baiersbronn-Klosterreichenbach/DE was chosen for the sorting and stacking plant. "We looked at several providers. Kallfass impressed us both in terms of the technical execution and the expertise of the employees", explained Lemaire, adding that "Kallfass is also active in further processing and has already supplied us with a bundling system for the planing line". Kallfass handled the project with its French representative, VBI from Barr/FR.

Excellent cooperation: Lemaire Project Manager Antoine Glé, Kallfass Managing Director Hans Haist, Lemaire Managing Director Maxence Lemaire, Lemaire Production Manager Anthony Receveur and Kallfass representative Jonathan Bleesz (from left)

Main and side products via a single line

The first log passed over the new saw line, which processes logs up to 55 cm in diameter, in September 2022. Larger dimensions are sent to the large diameter timber mill in Moussey. "Our goal is to cut 300,000 solid cubic metres per annum at both locations in the future. About 20 % of the volume involves large diameter timber", explains the Managing Director. All the main and side products produced on the new chipper line are conveyed separately on two decks to the Kallfass system. "The sorting and stacking system is designed for an output of up to 140 cycles per minute, lengths of 2 to 6.2 m and cross sections up to a maximum of 100 by 250 mm", relates Kallfass Managing Director Hans Haist.

New type of flexible alignment

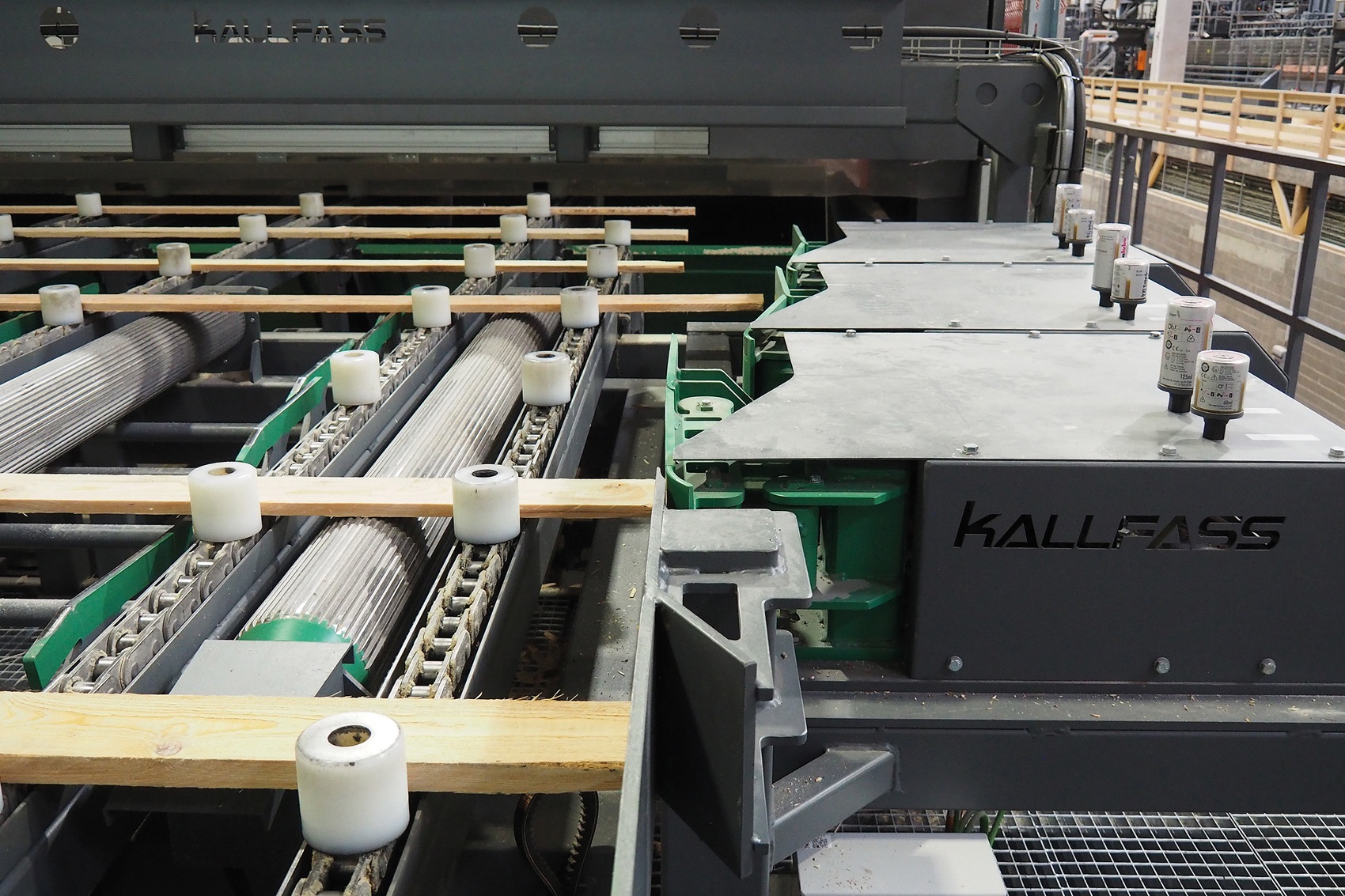

The timber is conveyed via a transverse buffer conveyor and a separation station to an assessment station where an employee checks the material and pulls the pieces forward for a subsequent trimming if necessary. The boards and squared timber then pass through a Goldeneye 900 scanner from Microtec. This determines the quality and dimension, transmitting the data on to the subsequent Kallfass trimmer. Kallfass installed a novelty between the Goldeneye and trimmer: a flexible alignment. "This can adjust the boards - depending on the scan result - by up to 300 mm with centimetre precision. This means that shorter cuts can also be made on the end faces, ultimately increasing the yield", explains Haist. The trimmer is equipped with 13 saws. The timber is then divided into 71 sorting boxes.

After the boxes have been emptied, the wood is fed to another employee for a follow-up check via a step feeder and separator. Following the creation of layers, the timber pass through the tried and trusted multiple circular cross-cut saw from Kallfass. This saw is equipped with four sawing units, three of which are completely automated and can be positioned as required. Remaining pieces are discharged via a waste belt in the direction of the Vecoplan disposal unit. "The downstream stacking line has a capacity of up to 14 layers per minute and is equipped with six double magazines for stacking", elaborates Jonathan Bleesz from VBI. The finished packages, which are mainly 600 mm high, are sent to the Fromm strapping unit. Kallfass supplied a squared timber milling machine for this purpose. As mentioned at the beginning, the Kallfass plant sorts main and side products. However, space for another side product sorting unit was already taken into consideration in the conceptual design.

Lemaire is convinced that investing in the new sawmill was the right step: "We have already been able to win four large customers who previously imported sawn timber. Now we can generate added value domestically".

Installed for the first time: The flexible alignment in front of the trimmer saw can compensate for up to 300 mm.

The trimmer saw from Kallfass has 13 chop saws arranged in a 50 cm grid.

„Kallfass impressed us in terms of technology. The cooperation has been impeccable.“

Managing Director Maxence Lemaire

Main and side products are divided into 71 boxes. There is still room for another sorting unit next to it should this be necessary.

The multiple cross-cut saw from Kallfass is equipped with four sawing units, three of which can be positioned automatically.

The stacking unit has six double magazines and a capacity of up to 14 layers per minute.