Automation solution

Glueing/Pressing

As a competent solution partner, we are your one-stop provider for tailored plant technology. We create automated production concepts for complete solid structural timber, glued laminated timber and cross laminated timber production lines and ensure planning security.

Installation example

From timber lamellas to multi-layer panels

von Holzlamellen EN Provision of timber lamellas

Reliable process preparation

The timber lamellas are first destacked by a vacuum and then separated into layers. Unsuitable workpieces can be identified and ejected with the aid of quality, strength and moisture measurements. In the next step, the lamellas are trimmed on the left and right at the front and in a transverse direction before being fed to the finger jointing system with the throughfeed press. The finger jointed lamellas can then harden on the buffer section of ca. 25 m before being fed to the planing machine.

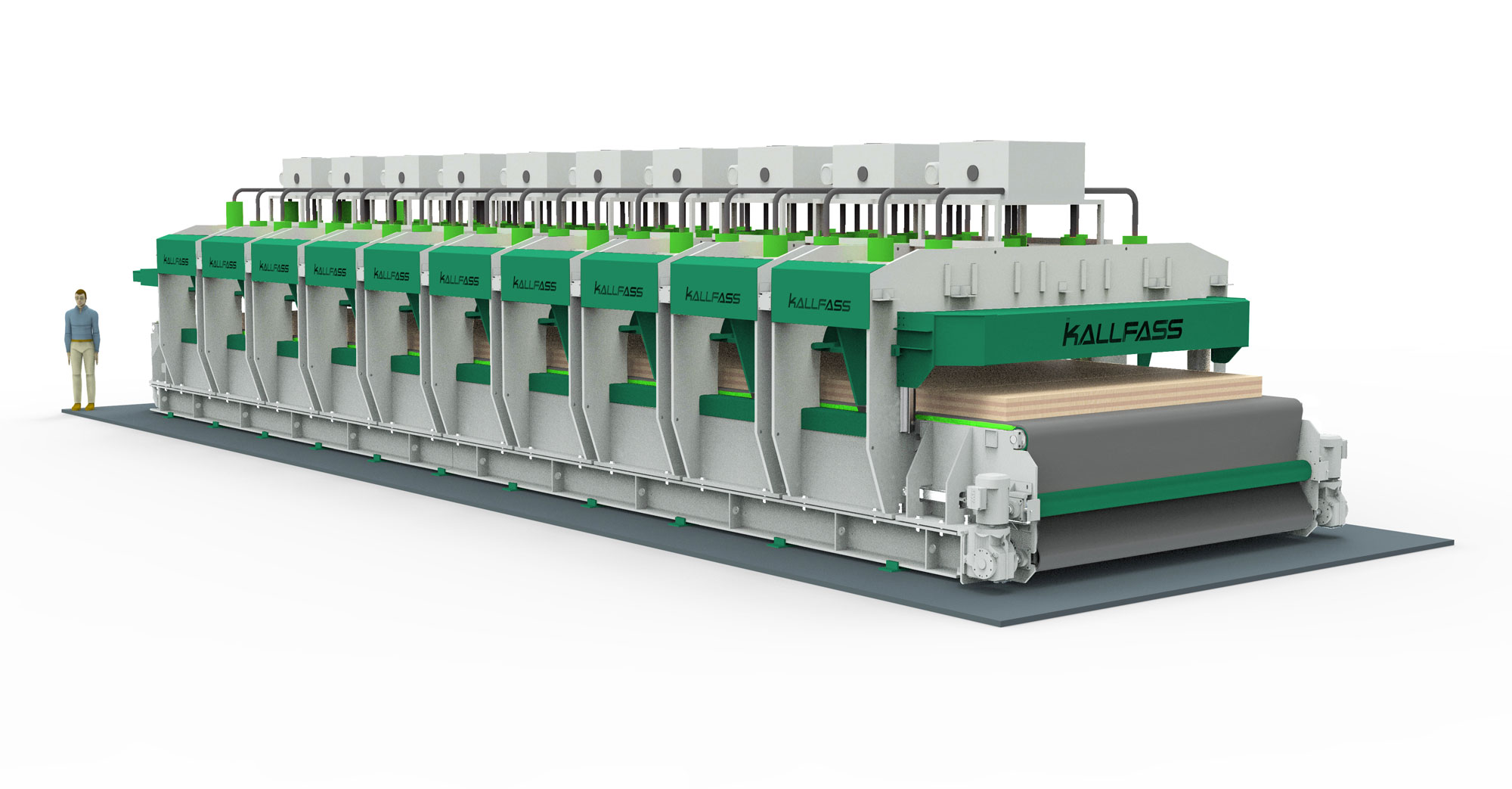

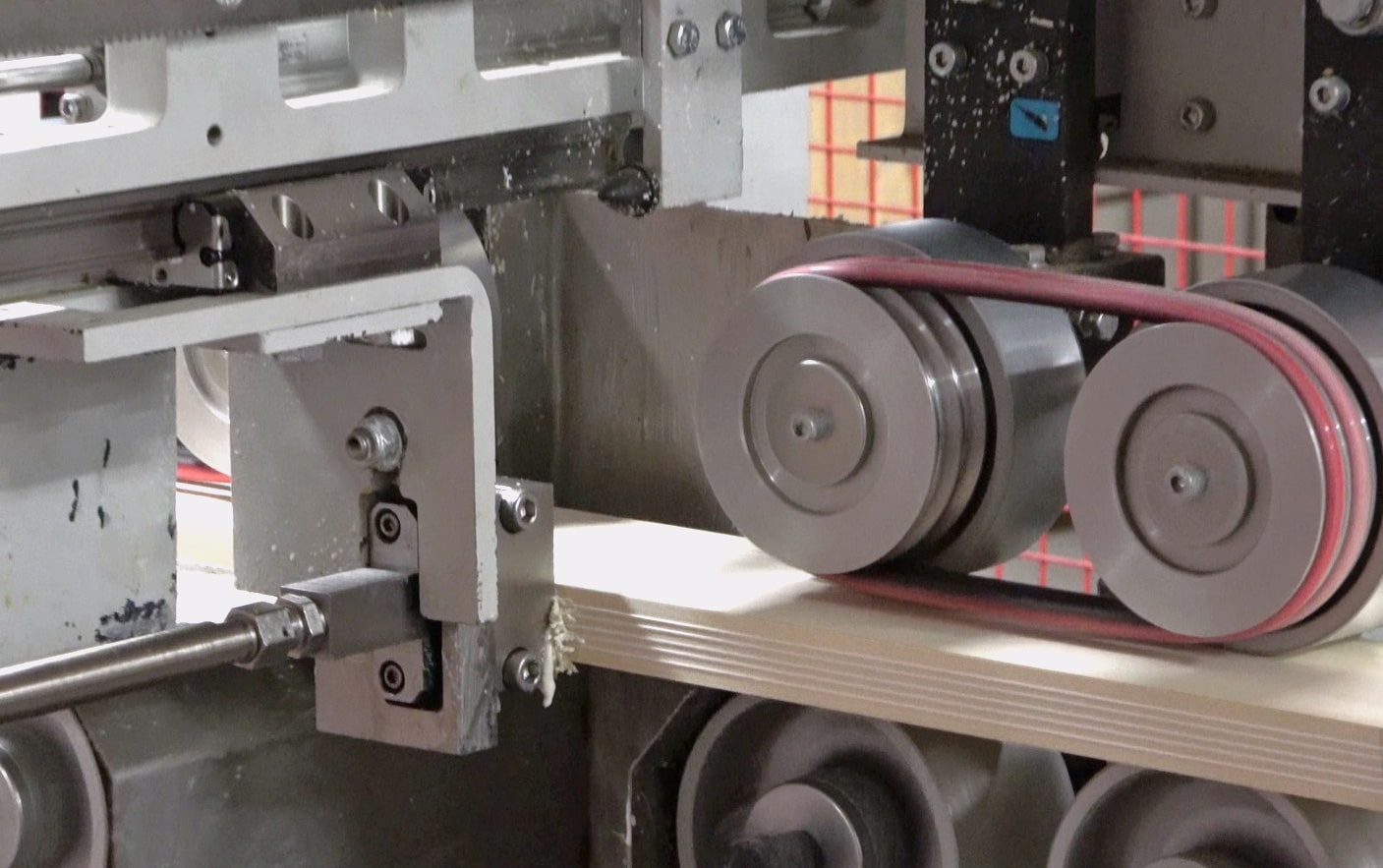

Pressen von Holzlamellen EN Edge glueing / pressing of timber lamellas

Clean bonding to form single-layer boards

After planing, the timber lamellas are cycled in the direction of the board press. Glue is first applied to the edge in the press before the glued lamellas are pressed together to form single-layer boards. The longitudinal layers are already trimmed to the correct width on being transferred to intermediate storage.

Precision cutting without scrap

Single-layer boards intended for transverse layers are automatically trimmed to the desired dimension, stacked and transferred to an automated store using a crane.

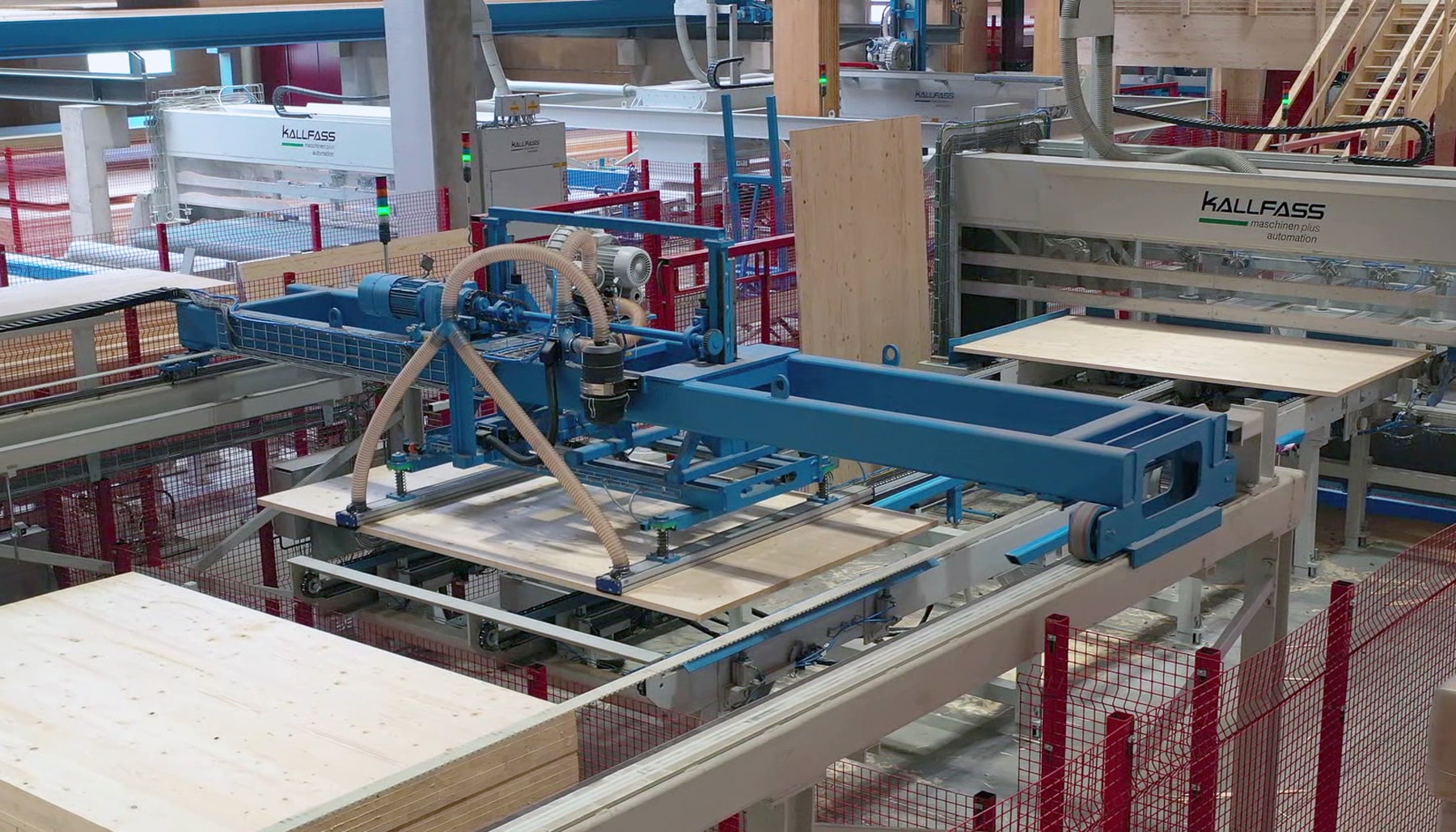

Quer-/Längslagen EN Provision of transverse / longitudinal layers

Maximum process reliability

The provision of transverse and longitudinal layers of single-layer boards encompasses a variety of individual processes such as vacuum stacking, aligning with subsequent turning of the boards (the better side of the board should be upwards during formation of layer packages) and trimming of boards in a transverse direction with downstream cleaning and stacking. Stacking of boards creates a material buffer that enables continuous supply of the glueing station, avoids stopping times and thus ensures a high degree of process reliability.

Optimum process utilisation

When creating layer packages, individual layers of single-layer boards are glued in a cross pattern to achieve a high degree of dimensional stability. Glue is applied uniformly over the entire board surface using a glueing portal. Following every glue application, a vacuum portal crane lays the next (alternating transverse or longitudinal) layer precisely, edge to edge on the glued board. The board structure of a layer package should have at least 3 layers and can be a maximum of 600 mm thick. In the case of a thin layer structure, several board assemblies can also be laid on top of each other with a dry joint in each case and, simultaneously, pressed to achieve better process utilisation.

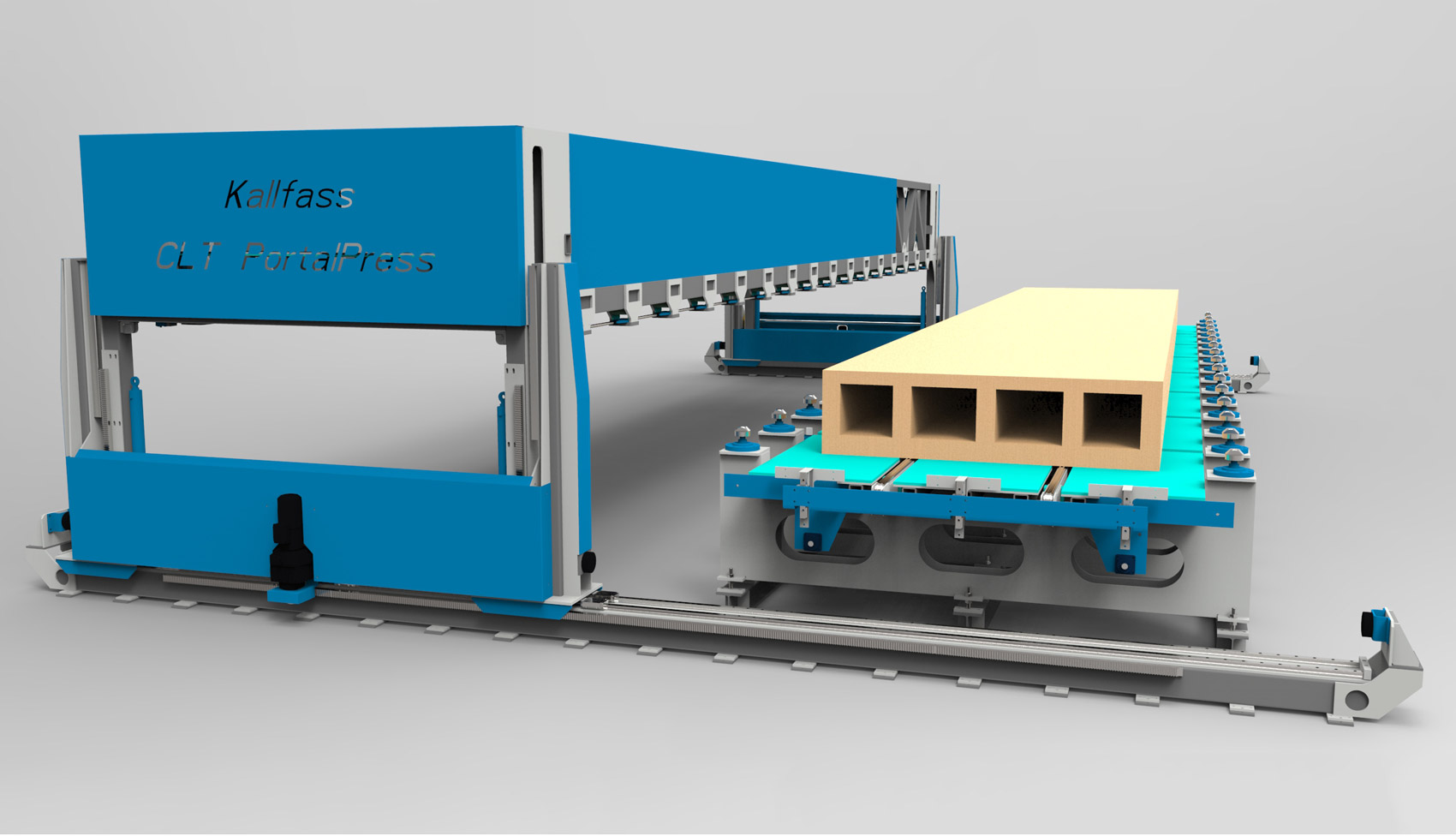

Constant pressing force

The Kallfass CLT press joins single-layer wood panels into muli-layer wood panels with tolerance values of maximum 0.1 mm. Achieving this zero joint is guaranteed through a very high vertical pressing force in combination with a uniform pressure distribution across the entire panel surface. A pressing pressure of 1 N/m² can be built up even with a maximum panel width of 3.6 m. As an option, the press can be offered with additional transverse pressure when pressing wooden lamellas. The result is a clean, homogeneous product.

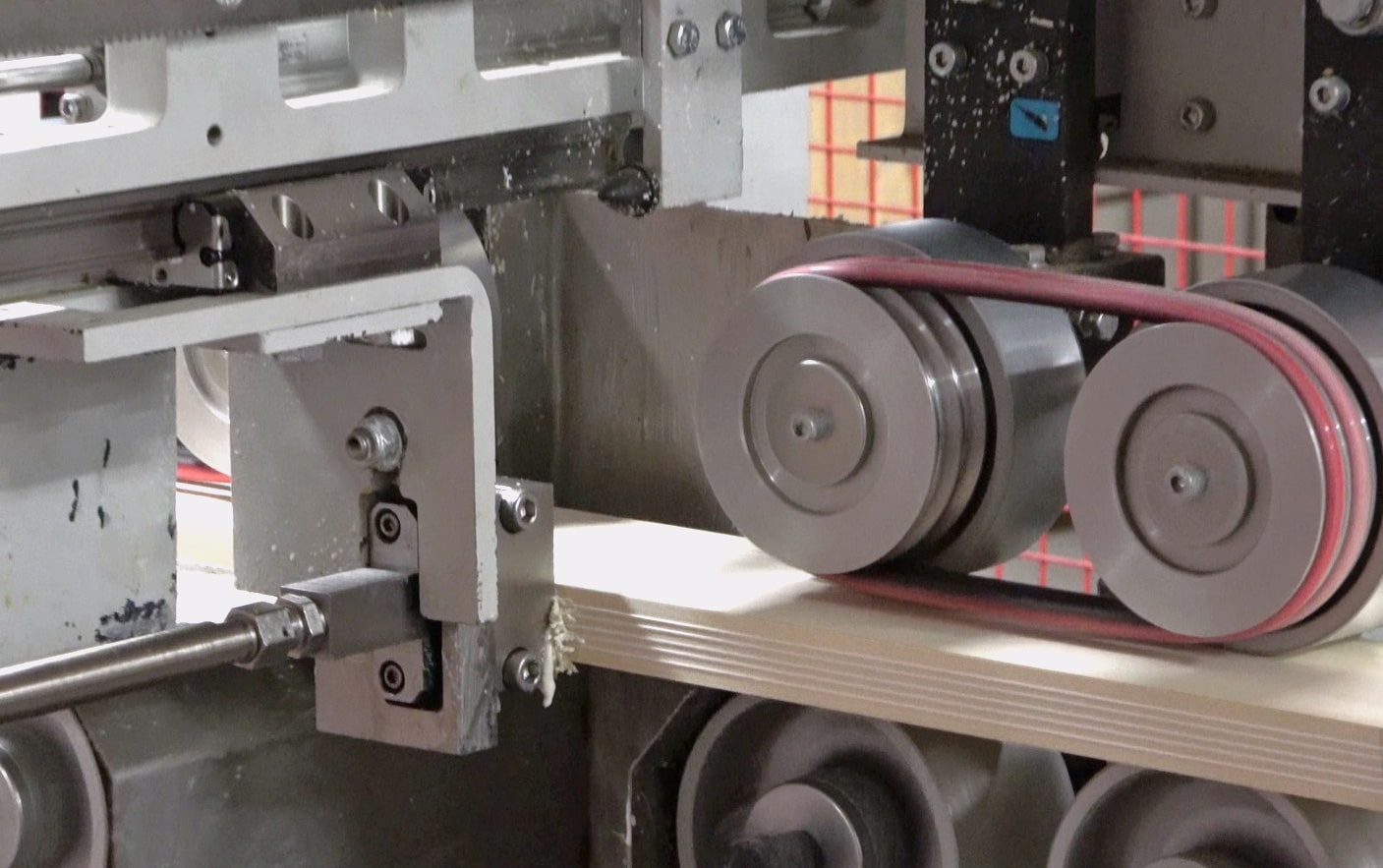

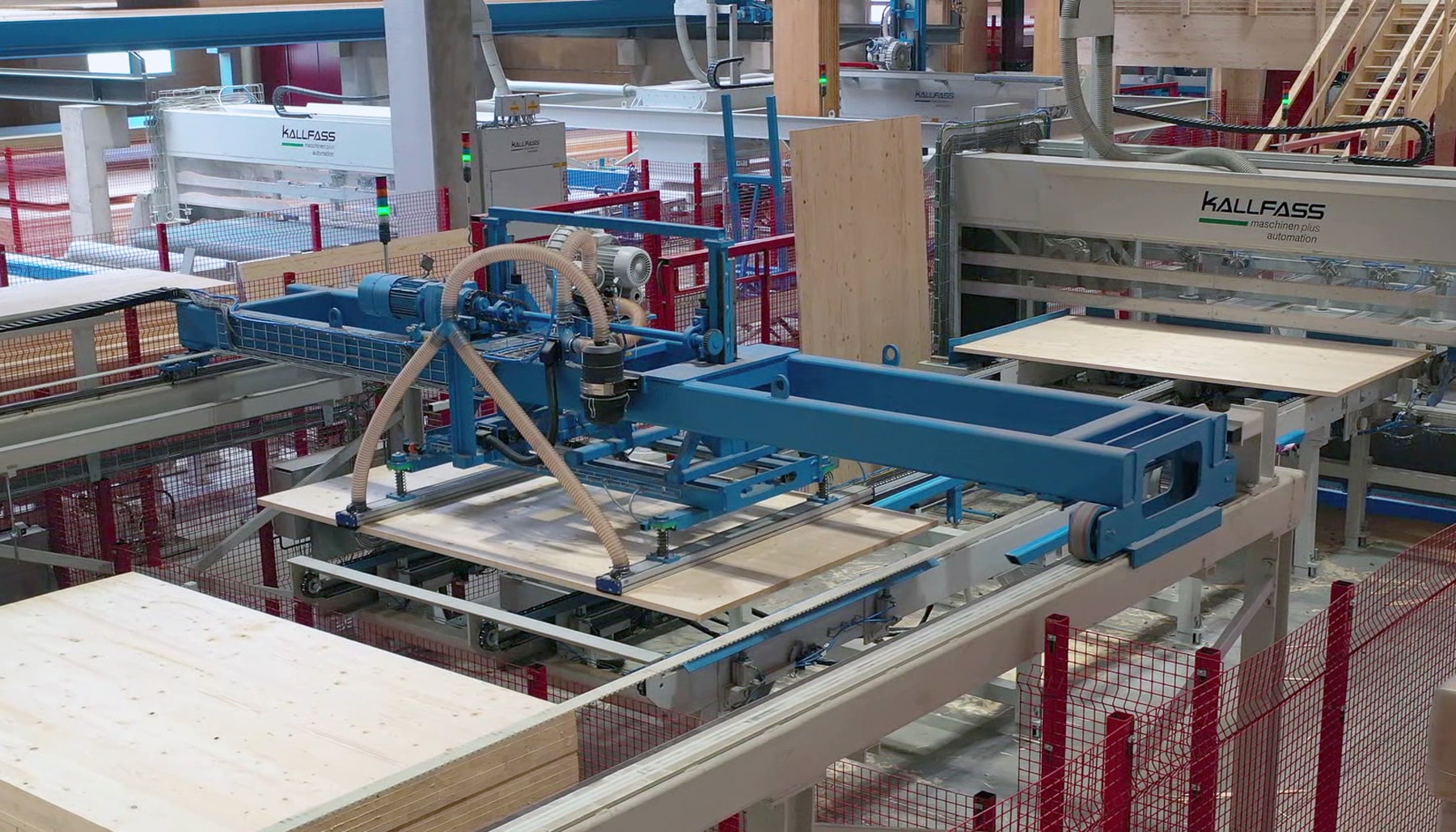

vereinzeln/schleifen EN Separating / sanding layer packages

Constant material flow

Following pressing, individual multi-layer panels laid on top of each other are pushed again on the dry joint and fed individually to the sanding process. In the final processing step, the multi-layer panel is transformed into a prefabricated timber construction element in portal processing centres by cutting out openings and ensuring surface cosmetic treatment.

Attractive product appearance

TURNING single-layer boards

Single-layer boards can be turned after destacking and aligning to improve the appearance of the final product. In this way, the more attractive side of the board faces outwards when creating layer packages. The final result is a perfect multi-layer panel.

Safe handling

TURNING large panels

It may be necessary under certain circumstances to process the large panel from both sides in the machining centre. The board is turned after a pass for this purpose and fed into the machining centre again. To avoid risky turning with a crane, Kallfass has developed a turning device that can also pick up large panels without breaking them and lay them gently on the conveyor.

Unambiguous classification

STRENGTH MEASUREMENT

Leading makes of multisensor scanner systems are used for strength sorting, measuring the timber precisely and classifying it at high production speeds pursuant to customer-specific quality requirements before it is forwarded on for planing, cutting to size or to sorting systems.

Consistent quality standard

MOISTURE MEASUREMENT

The water content of the timber is measured in mere seconds and without contact during moisture measurement. The analyser can be integrated at a flexible point in the production process. In the event of exceeding or undershooting the defined moisture level, the boards are marked behind the measuring head and rejected if necessary. Only timber that conforms to the desired classification is processed further, ensuring a consistently high quality standard.

Interactive installation example

Solutions from a one-stop provider

We regard ourselves as a solution partner that assumes responsibility, supporting you from initial consultation and the planning phase right through to successful commissioning of the production line. We train your operating personnel, provide you with comprehensive technical documentation and continue to support you after commissioning with advice and practical help.

von Holzlamellen EN Provision of timber lamellas

Reliable process preparation

The timber lamellas are first destacked by a vacuum and then separated into layers. Unsuitable workpieces can be identified and ejected with the aid of quality, strength and moisture measurements. In the next step, the lamellas are trimmed on the left and right at the front and in a transverse direction before being fed to the finger jointing system with the throughfeed press. The finger jointed lamellas can then harden on the buffer section of ca. 25 m before being fed to the planing machine.

Pressen von Holzlamellen EN Edge glueing / pressing of timber lamellas

Clean bonding to form single-layer boards

After planing, the timber lamellas are cycled in the direction of the board press. Glue is first applied to the edge in the press before the glued lamellas are pressed together to form single-layer boards. The longitudinal layers are already trimmed to the correct width on being transferred to intermediate storage.

Precision cutting without scrap

Single-layer boards intended for transverse layers are automatically trimmed to the desired dimension, stacked and transferred to an automated store using a crane.

Quer-/Längslagen EN Provision of transverse / longitudinal layers

Maximum process reliability

The provision of transverse and longitudinal layers of single-layer boards encompasses a variety of individual processes such as vacuum stacking, aligning with subsequent turning of the boards (the better side of the board should be upwards during formation of layer packages) and trimming of boards in a transverse direction with downstream cleaning and stacking. Stacking of boards creates a material buffer that enables continuous supply of the glueing station, avoids stopping times and thus ensures a high degree of process reliability.

Optimum process utilisation

When creating layer packages, individual layers of single-layer boards are glued in a cross pattern to achieve a high degree of dimensional stability. Glue is applied uniformly over the entire board surface using a glueing portal. Following every glue application, a vacuum portal crane lays the next (alternating transverse or longitudinal) layer precisely, edge to edge on the glued board. The board structure of a layer package should have at least 3 layers and can be a maximum of 600 mm thick. In the case of a thin layer structure, several board assemblies can also be laid on top of each other with a dry joint in each case and, simultaneously, pressed to achieve better process utilisation.

Constant pressing force

The Kallfass CLT press joins single-layer wood panels into muli-layer wood panels with tolerance values of maximum 0.1 mm. Achieving this zero joint is guaranteed through a very high vertical pressing force in combination with a uniform pressure distribution across the entire panel surface. A pressing pressure of 1 N/m² can be built up even with a maximum panel width of 3.6 m. As an option, the press can be offered with additional transverse pressure when pressing wooden lamellas. The result is a clean, homogeneous product.

vereinzeln/schleifen EN Separating / sanding layer packages

Constant material flow

Following pressing, individual multi-layer panels laid on top of each other are pushed again on the dry joint and fed individually to the sanding process. In the final processing step, the multi-layer panel is transformed into a prefabricated timber construction element in portal processing centres by cutting out openings and ensuring surface cosmetic treatment.

Optional equipment

The added bonus for your success! This equipment allows you to enhance your product quality while simultaneously reducing changeover times and personnel costs.

Attractive product appearance

TURNING single-layer boards

Single-layer boards can be turned after destacking and aligning to improve the appearance of the final product. In this way, the more attractive side of the board faces outwards when creating layer packages. The final result is a perfect multi-layer panel.

Safe handling

TURNING large panels

It may be necessary under certain circumstances to process the large panel from both sides in the machining centre. The board is turned after a pass for this purpose and fed into the machining centre again. To avoid risky turning with a crane, Kallfass has developed a turning device that can also pick up large panels without breaking them and lay them gently on the conveyor.

Unambiguous classification

STRENGTH MEASUREMENT

Leading makes of multisensor scanner systems are used for strength sorting, measuring the timber precisely and classifying it at high production speeds pursuant to customer-specific quality requirements before it is forwarded on for planing, cutting to size or to sorting systems.

Consistent quality standard

MOISTURE MEASUREMENT

The water content of the timber is measured in mere seconds and without contact during moisture measurement. The analyser can be integrated at a flexible point in the production process. In the event of exceeding or undershooting the defined moisture level, the boards are marked behind the measuring head and rejected if necessary. Only timber that conforms to the desired classification is processed further, ensuring a consistently high quality standard.