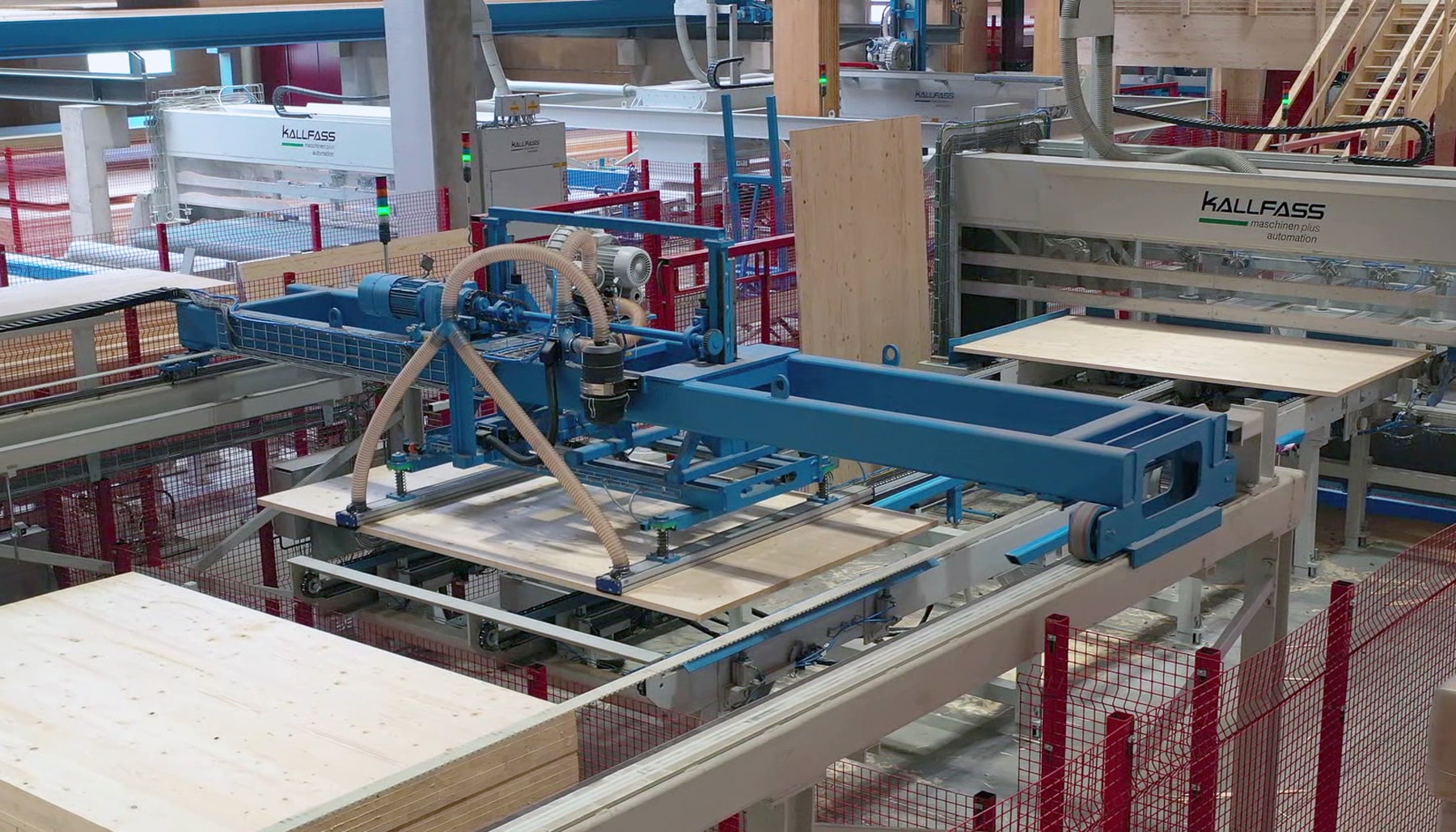

Kallfass, located in Baiersbronn/Germany, is well known as a mechanisation specialist. The same applies to the fact that the mechanical engineering company equips cross laminated timber systems. With this in mind, we can refer to some well-known projects. Recently Kallfass has added a CLT press (Cross Laminated Timber) and a CLT turning device.

The mechanical engineering company Kallfass from the Black Forest has already been involved as a supplier in several cross laminated timber projects in Austria and Germany. The most recent work completed was that of Stora Enso in Gruvön/Sweden. Construction work on this site began in 2018 and the system has been running in automatic mode since the beginning of 2019.

To date, this is the largest project for Kallfass in the area of cross laminated timber applications. The company not only supplied the entire mechanical equipment—from the feeding of packages to the acceptance of the finished pressed elements—but was also responsible for the overall layout and the complete safety control system. The fact that Stora Enso has selected Kallfass as its supplier is probably also due to the fact that Kallfass has already been involved in the Austrian CLT plants in Ybbs and Bad St. Leonhard, Austria. The total capacity in Sweden totals 100,000 m3/year.

Large packages also possible

Stora Enso also operates a sawmill in Gruvön, Sweden which supplies the raw materials for the laminated timber elements. The sawn timber (dried and battened or pre-planed) is transported by truck to the Kallfass feeding station. This feeding station is also designed for large packages up to 5.8 m long, 2 m wide, and 3 m high. A vacuum-operated de-stacking device separates the packets layer-by-layer. If stacking strips are available, a brush automatically scrapes them off and collects them. The Kallfass mechanism separates the layers and feeds the boards piece by piece to Finscan's quality scanner. In this area, the strength and the moisture of the timber is also measured. Any unsuitable workpieces are ejected from the process.

Two paths for the boards

“The scanner provides us with the information whether there are cracks on the front sides or knots in the base of the finger joints. If this is the case, we trim the front sides," says Kallfass Managing Director Hans Haist. The boards pass through a front end cross-cut with adjustable servo stop. Subsequently, the zero line is changed and the same process takes place on the other side of the board. If the scanner also finds undesirable wood features in the centre of the board, these pieces are ejected to an upper level where a cross-cut system made by PAUL Maschinenfabrik GmbH cuts out these areas. “However, this concerns only about 5% of the total quantity. Most of it goes straight on to the Grecon finger-jointing system”, describes Kallfass Project Manager Helge Widmann.

The Kallfass mechanisation cycles both the long workpieces and the cross-cut lengths from 800 mm upwards at a rate of up to 50 boards per minute. They travel in the direction of the finger-jointing system with the continuous press. Subsequently, the mechanisation takes over the finger-jointed lamellas again downstream of the moving cross-cut saw. These lamellas are between 8 and 16 m long. The applied adhesive can now cure on a 25 m long buffer section before Kallfass feeds the lamellas into the Rex planing machine. After the lamellas are pre-planed, they are cycled in the direction of the board press: First, a system provided by OEST Mineralölwerk GmbH, applies a layer of adhesive to the the lamellas. Subsequently, these lamellas are fed into the glueing press made by DIMTER GmbH. The single-layer boards produced in this way are then taken over again by a Kallfass system.

This is where the paths split: A VOITH crane picks up the longitudinal layers and transfers them to the intermediate storage. Previously, a chop saw, installed downstream of the glueing press, has already cut the longitudinal layers to the width required by the order. In order to make the best possible use of the DIMTER press, the longitudinal layers are always produced in 16 m lengths wherever possible. If shorter boards are required, Kallfass has developed a special system to recycle the remnants of the longitudinal layer.

Transverse layers measuring up to 1.5 m are stacked by Kallfass to a height of 2 m and are also transported by a VOITH crane to a second storage area. These processes are fully automated. A controller determines the suitable storage location.