References

This is what production is like in the wood processing industry. Find out how your peers in the industry have successfully implemented automation projects in practice

Current References

Ein BSP-Werk für Profis EN A CLT plant for professionals

In the CLT plant at best wood Schneider in Meßkirch, Kallfass is responsible for...

read moreBis auf den letzten Millimeter ausgenutzt EN Utilised down to the last millimetre

In the new sorting and stacking plant at Åsljunga Pallen in Sweden, attention was...

read moreErstes gemeinsames Projekt erfolgreich abgewickelt EN The first joint project has been successfully completed

The new Kallfass restacking system at Robeta Holz has become a real reference project...

read moreNeue Stapellinie mit einer technischen Raffinesse EN New stacking line with technical sophistication

The new stacking line from Kallfass makes it possible to form sawn timber packages...

read moreAll References

Precision stacking and packing of pallet boards

CBD Bois in France invests in a new cutting, stacking and packing system from Kallfass. The system effortlessly stacks multiple lengths to create secure transport packages.

Optimum short log handling

Plant configuration from Kallfass designed for short timbers and consisting of mechanisation, sorting and stacking ensures optimum handling for Juodeliai in Lithuania. Side boards are collected in five buffer...

Sorting system for wet and dry

Mostovdrev in Belarus has invested in an automated Kallfass sorting system for wet and dry timber.

Flexible planing of small batches up to 8 m in length

Van Roje planing mill. Given frequent product changes, a high degree of production flexibility and a quicker dimension change were among the core requirements of Kallfass mechanisation.

Flexible sorting

Kallfass provided Kolb with the best concept for a combined sorting and stacking plant. Side products and part of the main product up to 6 m in length are...

Equipped for every dimension

Perfect commissioning of the new high-performance planing line at Rettenmeier in Ramstein, Germany. An output of almost 100 % was achieved after only four weeks, and 6000 m³ of...

Glued timber plant has it all

For the production of glued timber rib elements, Kallfass developed a new production process together with Best Wood Schneider.

A 4 m package every 50 seconds

The modern planing mill at Cordes is a universal system that can do everything from stick to squared timber planing.

Automatic Benefits

The Murray Timber Group is proud of its new Kallfass stacker line with robot stick handling. According to MTG it is exactly the solution they had been searching for...

An Absolute Jewel:

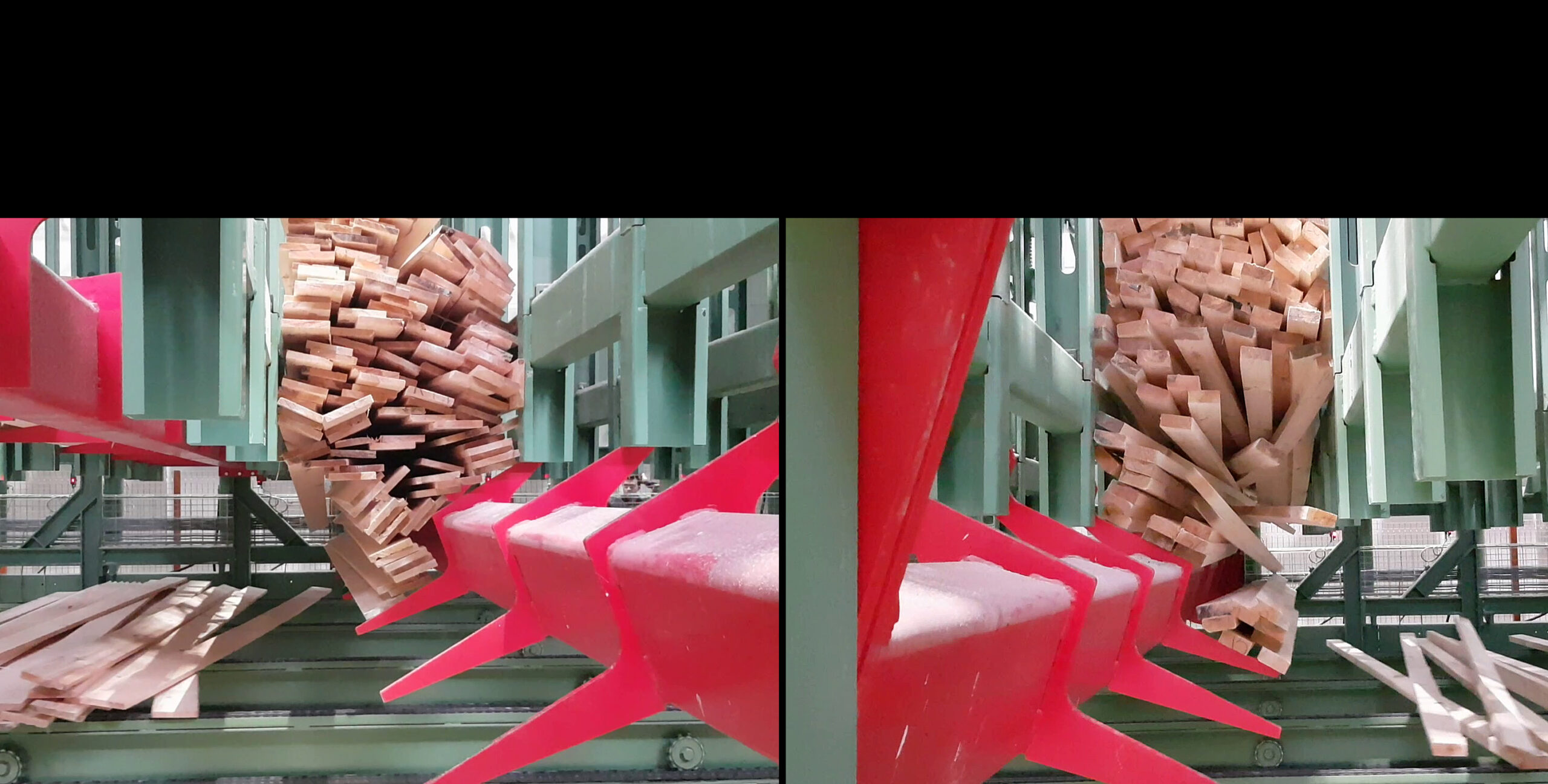

New Small Diameter Sawmill

New Small Diameter Sawmill

GELO Timber decided to pick a sorter with 40 inclined boxes. The boxes are around 30 % larger and therefore suitable for dimensions with a width of up to...

Continuous inflow with stick robot

Quote from Egger sawmill: “We anticipate the new stick handling system paying off within a very short space of time”.

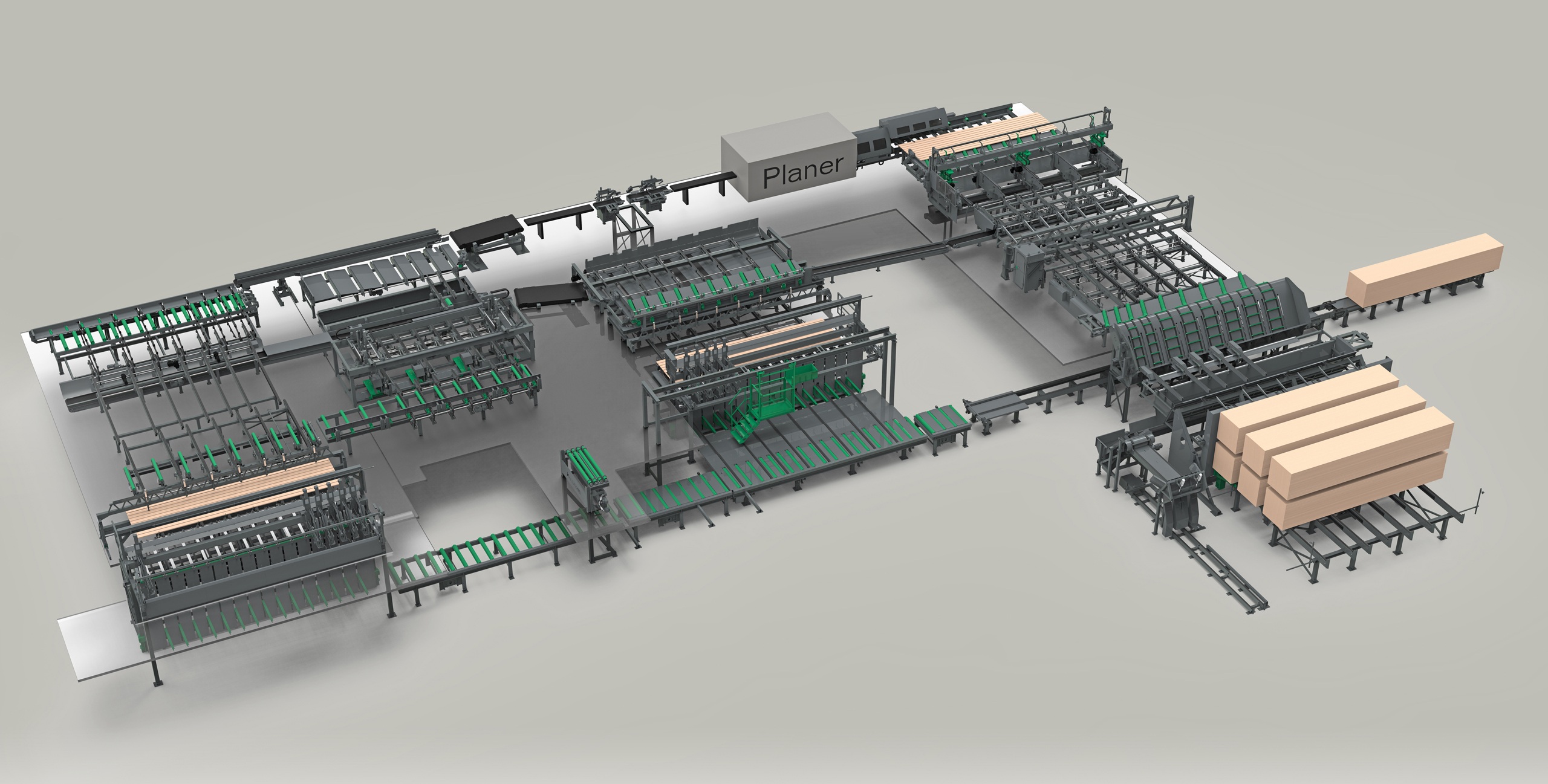

Flexibility raised to a new level

The 12 October 2019 saw commissioning of the new sawmill at Hegener-Hachmann. This involved probably the most flexible production processes every realised in a medium-sized sawmill enterprise.