Exceptional overall concept sets new standards

Log in, finished CLT element out - and all without a forklift. This is how you could describe best wood Schneider's extremely ambitious Greenfield project in just a few words. At the newly founded site in Meßkirch, Germany, the company is implementing a trend-setting, end-to-end production line. Currently the CLT plant is being commissioned. The planned output in the sawmill is 350,000 cubic meters/year. After the final expansion, the CLT production will reach an output of 100,000 m³/year. As in the sawmill, Kallfass also plays a leading role in further processing.

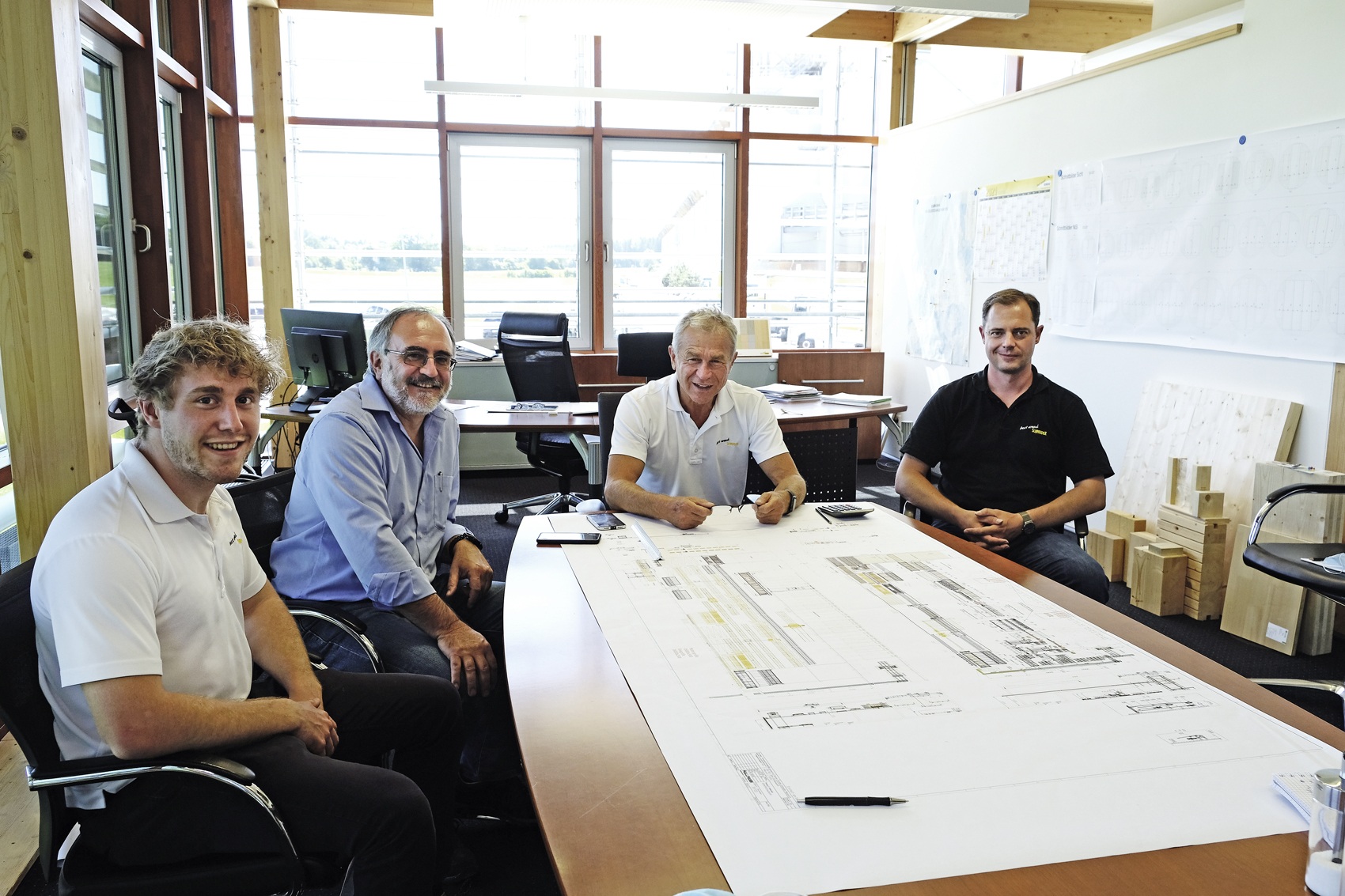

Actually, best wood Schneider “only” wanted to build a cross laminated timber plant at the new Meßkirch site. “Large-format CLT was the only product that we still lacked as a complete supplier for our approximately 5,000 active timber construction customers”, reports Managing Director Ferdinand Schneider during the Holzkurier visit. In addition to solid structural timber (KVH), glulam, glued laminated timber and box girder elements, the family-owned company offers its customers numerous wood fibre insulation systems as well as comprehensive planning and consulting services.

“But then we decided to do it right from the logs and to realise a continuous line from the logs to the finished timber construction products”, says Schneider, describing the process that began seven years ago with the planning phase and continues to this day. According to Kallfass Project Manager Stefan Günther, this constant development and improvement of ongoing projects, both large and small, is characteristic of the company: “Schneider projects are organic and continue to grow. However, these further developments are always constructive, with the best solution coming out on top, regardless of who it comes from”.

The basic idea for Meßkirch was as follows: to implement a continuously automated material flow–from the log feed to the finished and glazed CLT and box elements for walls and ceilings–completely without forklift traffic and almost without manual intervention.

The dried raw material is transported from the sawmill ...

directly to the next hall, using conveyor belts.

There, the timber is assessed, stacked and temporarily stored in a high-bay warehouse. From there it continues to the BSP line or onto the lorry.

Well-established team

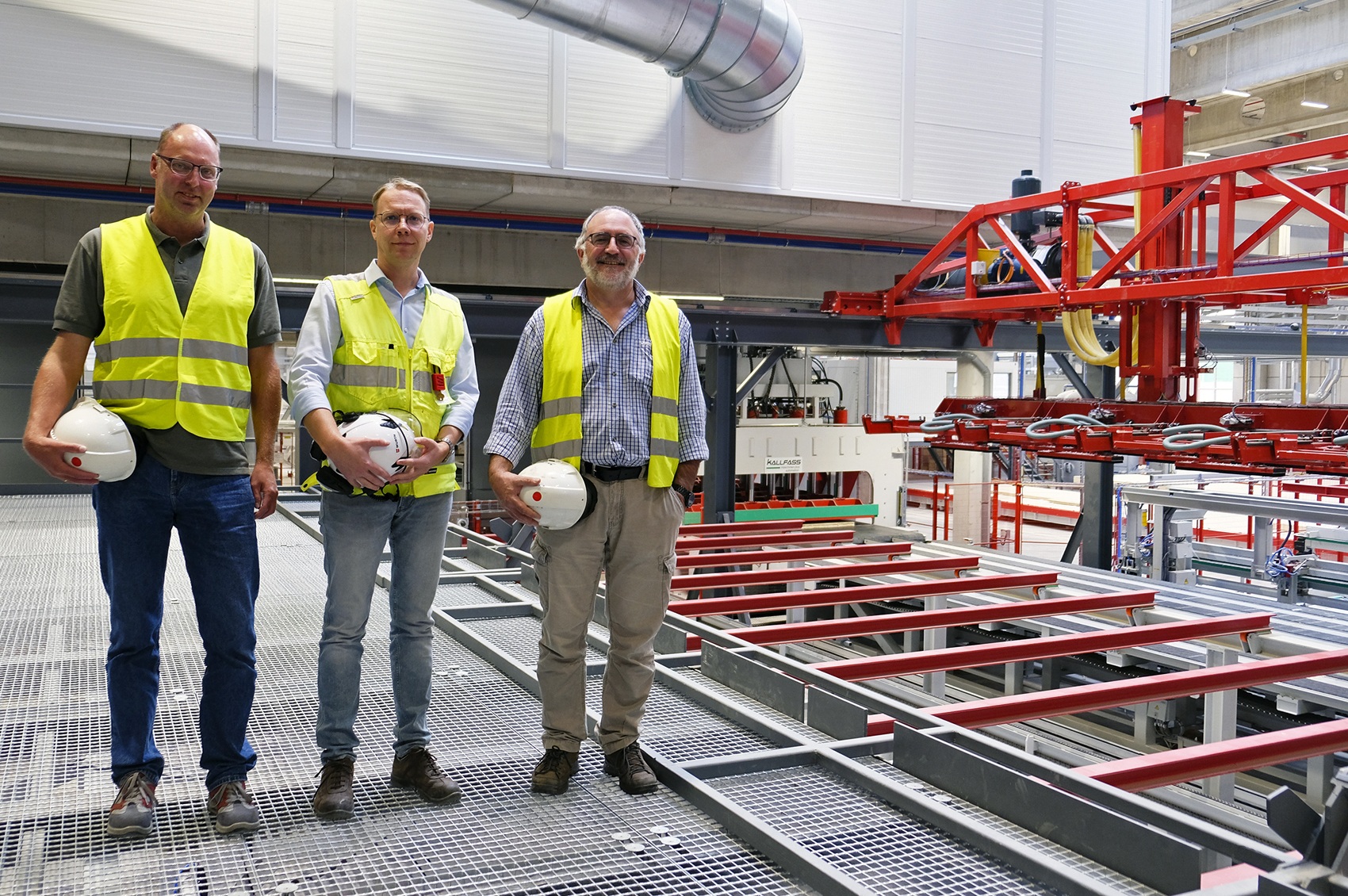

While the sawmill is already rapidly approaching full-load operation, the first expansion stage of the CLT plant is in the middle of the commissioning process. As in the sawmill, Kallfass is responsible for the majority of the mechanisation, the cross laminated timber press and numerous detailed solutions. “In addition, Kallfass, as our vendor of choice, had the planning authority”, adds Schneider, who has already successfully completed numerous projects with the Black Forest system specialists.

Conveyor belts provide the transfer between the sawmill and processing steps down the line. Subsequently, the dried and sorted goods are transported to a Microtec Optiside cup scanner, where the timber is turned to the correct side, if required. In the next processing step, the planer infeed, also from Kallfass, accelerates the goods up to 250 m/min before they are levelled and scanned, and defects are marked. The timber is then packaged in a crosswise offset, strapped if necessary, and fed on roller conveyors to a high-bay warehouse with 1,450 storage locations.

Precise production

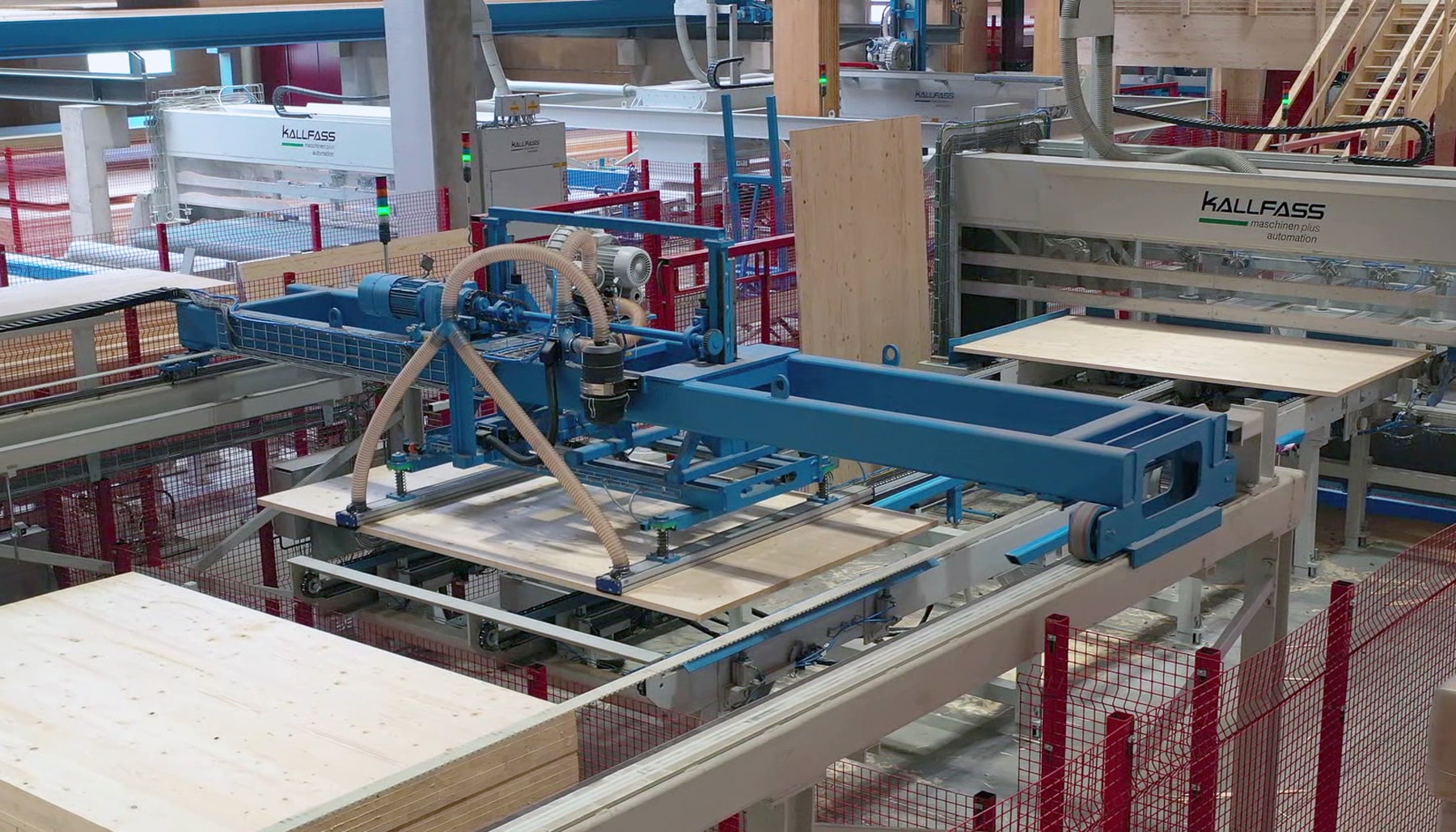

For cross-laminated timber production, the pre-planed raw material from the high-bay warehouse is transferred to a finger-jointing line and then to a longitudinal press. Here, white glue or hot melt is used to create an assembly joint. A vacuum lifter removes the assembly joints and transfers them to another part of the Kallfass system.

Whilst the longitudinal layers are directly used to lay a dry press cake in reverse order, cross-layer segments are produced from some of the single-layer boards. “As the longitudinal layer press always produces exactly a multiple of the desired cross-layer length plus kerf, our cross-layer saw does not produce any waste”, emphasises Günther, adding that particular attention is paid to precision when formatting the individual layers and when subsequently arranging the cross-layers and laying the boards. “This means that the panel no longer has to be formatted with a saw after pressing, which saves us time and, above all, material," emphasises Schneider, who runs his panels through a sanding system, a cross-cut saw and a multi-spindle processing machine for the production of any profiles between the press and the joinery systems.

In the cross-layer production process, the single-layer panels are cut to length using high precision and joined together to form cross-layers.

Ingenious details

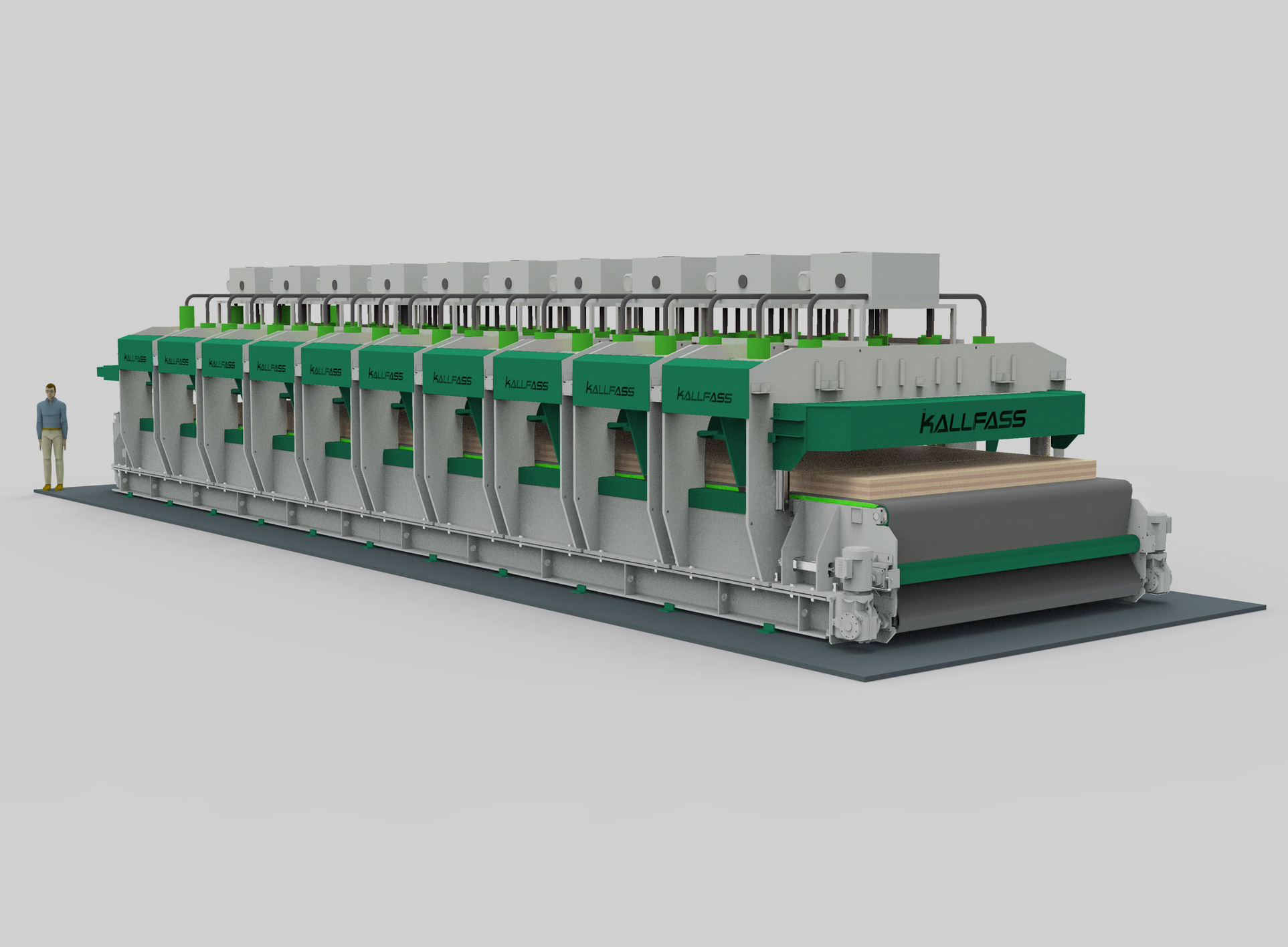

When laying the dry cake in reverse order, the single-layer boards are sprayed with water on both sides for the upcoming glue application before they are placed in the actual laying station. Apart from the adhesive application system from Oest, Kallfass is also responsible for the entire plant construction, including the subsequent cross laminated timber press. The latter can hold elements measuring up to 3.6 x 16 m and a maximum thickness of 360 mm.

Once the boards have been pressed, sanded and profiled, they move on to one of Technowood's joinery lines, where Kallfass also carries out the mechanisation upstream and downstream of the machines. This includes a specially developed panel turner for CLT, which enables the elements–which may weigh several tonnes–to be turned quickly and safely.

“This means that Kallfass is responsible for the end-to-end material flow–from sorting in the sawmill to the finished panel–and I have to say that all the parts they have implemented run flawlessly”. Schneider praises the installation and the Kallfass team.

Managing Director Ferdinand Schneider (right) together with Kallfass Project Manager Stefan Günther.

Still a lot to do

While the existing line at Schneider is designed for the production of large-format wall and ceiling elements in non-visible quality, the second line will eject elements in visible quality including glaze. Commissioning is scheduled for the coming winter. As a third expansion stage, the Managing Director mentions a production facility for hollow box and rib elements, as used in roof and ceiling constructions, which Schneider summarises under the “Box” product line. This means that the company will have numerous other essential products in its portfolio for its customers.

Schneider describes the planning and implementation of a cross-laminated timber line as extremely complex, whereby he believes there is no ideal solution: “Depending on the objectives and framework conditions, each new CLT plant is always a path of the best compromises, which we realise together with Kallfass in the best possible way”.

In the cross-layer production process, the single-layer panels are cut to length using high precision and joined together to form cross-layers.

The cross laminated timber press is just one of many components that Kallfass implemented in best wood Schneider's new CLT plant.