Sawmiller Charles Ransford & Son’s latest investment is an automated post-pointing line which has helped to transform the operation.

Charles Ransford & Son proudly declares itself as a timber specialist operating since 1876. It has a rich history as a producer of British timber products operating on a 38-acre site at Bishops Castle in Shropshire. During this recent period of the Covid pandemic, the sawmiller has seen exceptional demand for its range of products, which include fencing (garden, commercial, agricultural and equestrian), gates, acoustic sound panels (such as motorway fencing) and pallets and packaging.Fencing and landscaping products represent the lion’s share of its production – 70 % of this material goes to stockists, 20 % to contractors and 10 % to the highways segment. Small volumes of carcassing and pallet/packaging wood are produced, but not a significant volume.

The 55 employees work on a single shift and deal predominantly with redwood (60 %) such as Douglas fir, with spruce accounting for the remainder. Its most recently available annual results show a turnover of approximately £17m in 2020, with sales and demand remaining high last year. “Since Covid, fencing and garden products went through the roof and we could not cut the wrong thing, basically everybody wanted it,” said Ransfords engineer Alex Cooper. The massive increase in demand seen in 2020 and 2021 has since moderated in recent months to more normal seasonal demand.

To stay on top of things, Ransfords has a policy of continuous investment, with about £20m invested in the sawmill in the past 12 years. An EWD sawing line was the largest single investment. One of its main technology partners is German timber processing machinery specialist Kallfass. Its relationship with Kalfass extends many years. Ransfords bought a Kallfass saw stacker 26 years ago, followed by several investments including a drop sorting system 16 years ago. The most recent investment, completed in March 2022, was an automated post-pointing line, while a tray-sorting system for large items is currently being installed at the sawmill.

Zero point alignment takes place before the post-pointing station.

Four circular saws cutting the posts on all four sides.

Kallfass automated post-pointing system

The intention with the Kallfass automated post-pointing line was to increase productivity in the fence and gate post production by reducing manual work. The previous manual post-pointing and feeding of the incising system had been a very time-consuming and labour-intensive manual process.

The project was first discussed between Ransfords and Kallfass about 5 years ago, before the Covid pandemic. At first the focus was automating the feeding process for Ransfords’ incising operations. After Covid hit, discussions took place remotely on Microsoft Teams, but the Ransfords team was able to visit an automated post-pointing system that Kallfass had installed at A J Scott in 2020.

“It was all on Teams, it is a big advantage to have that tool and to show Ransfords what we were able to deliver,” said Matthias Link, Kallfass sales manager. “The decision was made really fast. “Kallfass and Ransfords have a really trustworthy relationship and that gives us the ability to do business in that way and it was a big advantage.” “This whole project went really well despite not able to meet up, with all the meetings done remotely,” added Ransfords mechanical engineer James Davies.

Previous to the new Kallfass line, Ransfords operated a Stenner bandsaw for pointing in a manual sawing and stacking process. For gateposts, a manually fed Graule crosscut saw was used, while round-topping was completed on a small individual machine. The new line is designed to process posts with a width of 75-200mm and length of 1.5-3m, with stacked packs being 1.2m x 1.2m.

It starts with a longitudinal push-off destacking with strip stripping, followed by automated feeding of an RJH Enterprise incising system. Before incising, bad quality wood is marked manually with luminous chalk. After incising a lumi sensor on the sorting conveyor detects the coloured marked wood and opens a flap for disposal via a chute. Then zero point alignment takes place before the post-pointing station. Four circular saws with a maximum 200mm cutting depth point the posts on all four sides, with pieces turned three times automatically between saws.

A radius milling cutting station for round-topping of square or rectangular posts.

Before milling, the posts are fixed in a clamping station.

A radius milling cutting station is designed for round-topping of square or rectangular posts, complete with clamping operation. Two motors, one turning in- and one against feed direction save the quality without tears at the edge. This station can process 5-6 pieces per minute.

Kallfass’ stacking system stacks sawn posts in single or multiple lengths with automatic stick placement at a rate of five layers per minute. The final strapping operation was a Mosca system sourced by Ransfords and integrated by Kallfass.

Reduced manual handling

“In terms of the actual machines themselves,” said Mr Cooper, “it has removed massive amounts of manual handling. “The operators don’t have to touch the wood, whereas beforehand two or three people were handling quite big pieces such as 200mm x 200mm gateposts. All of that aspect has been removed so it is significantly safer.” Staff have been redeployed in the new line.

“We can react to orders quicker now,” added Mr Davies. “In the past we tended to do products on an order by order process, but because of the way these machines work we try and batch produce and hold more in stock of the more popular products.”

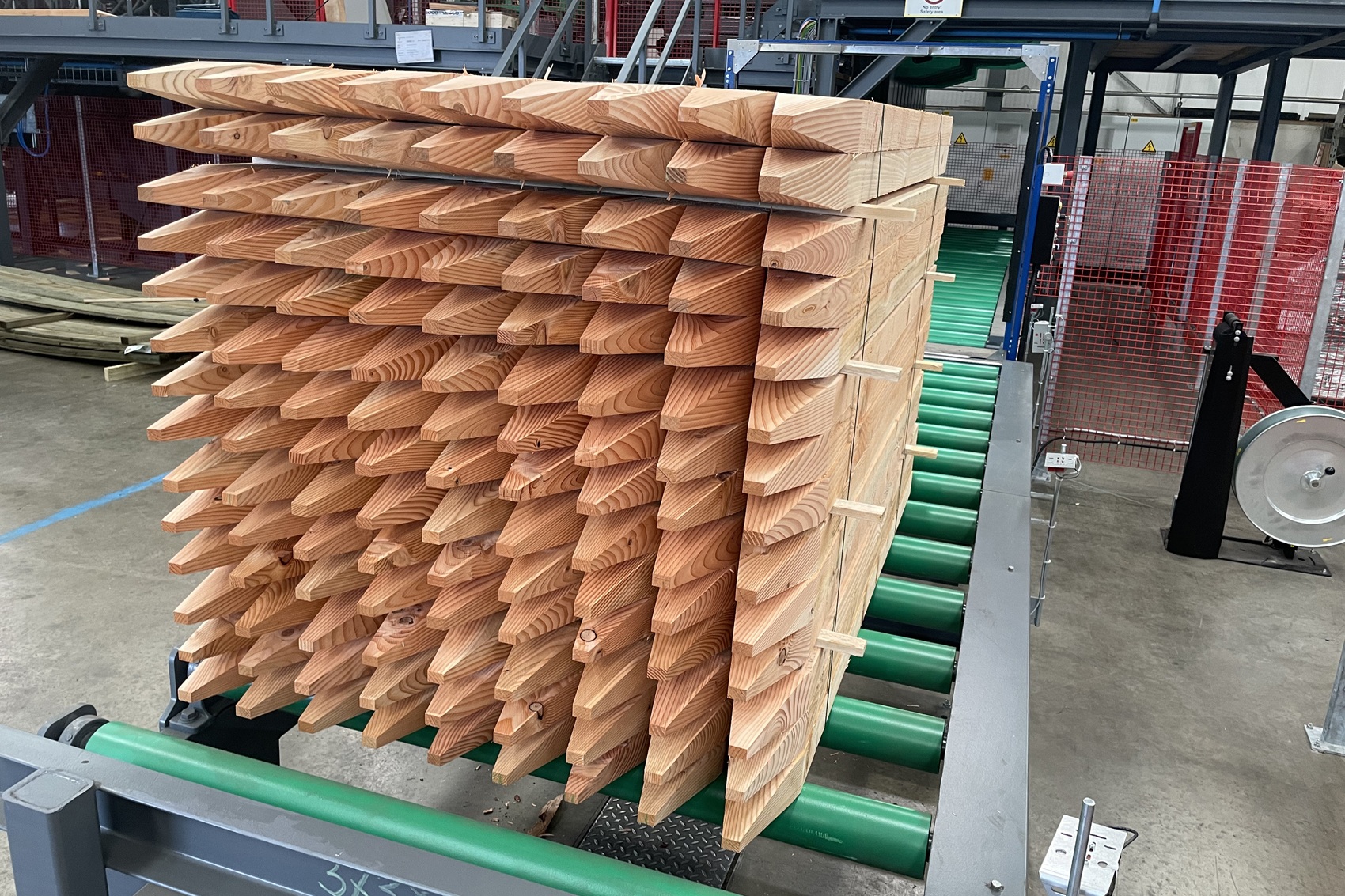

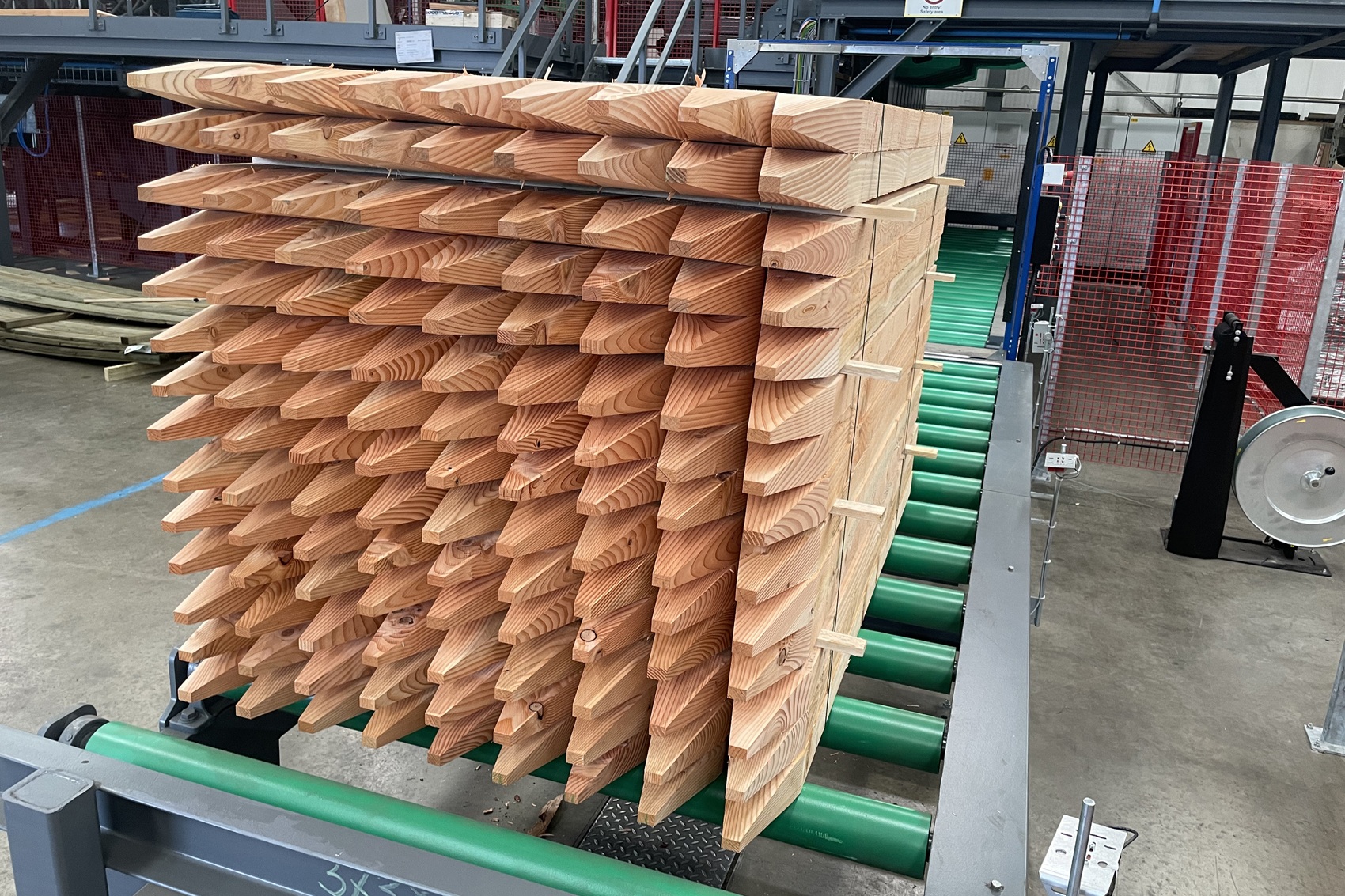

Finished stacking package with pointed posts.

“Even when the pointed part of a fence post goes in the ground, it’s good the customer can see down the side of the pack that all the points are in line and all look the same. That’s part of the Ransfords quality we strive to achieve.”

James Davies, mechanical engineer at Ransfords

Previously, the manual process to produce a four-way pointed post measuring 125x75mm would take three operators 30min to produce a pack of 126 pieces. Now it can be done in 5-10mins. The round-topping and incising process is also now considerably quicker. It used to take two hours to complete the manual incising and round-topping process for a pack, as opposed to approximately 10mins on the Kallfass line. The quality of finish is also important, particularly with gateposts which are a visible feature at the entrances of properties.

“If someone is doing this cutting by hand there might be a discrepancy, maybe you get a slightly different angle on each side,” said Mr Cooper. “On the new line, the machine guarantees every cut is the same.” “Even when the pointed part [of a fence post] goes in the ground, it’s good the customer can see down the side of the pack that all the points are in line and they all look the same,” added Mr Davies. “That’s part of the Ransfords quality we strive to achieve.”

With the incising process, Ransfords had been unable to visit the supplier RJH during Covid restrictions, but it did visit a similar unit at James Jones to see it in action. The existing AV Birch incisor is still being used for small orders or orders of longer lengths. “Incising seems to be the new normal now, the standard,” said Mr Cooper. “For instance, part of the Highways Agency’s requirement is the posts are incised and treated to UC4 to achieve 30 years’ service life.”

Further investment

The automated post-pointing line is not the only recent investment at Ransfords. In 2018, a building was constructed on site to house a new treatment plant, comprising a high pressure autoclave and two working solutions tanks – one UC3 and the other UC4. The autoclave has a 30m3 capacity per trolley, using Wolman preservatives and is able to run 24/7. It represents a doubling of treatment capacity. A new biomass boiler was installed to heat the solution in the facility, while also heating the previously existing treatment plant, comprising of three small tanks and a kiln. “The new treatment tank was fantastic timing to cover the demand over the past two years, because the old trolleys would only hold 15m3, so there is a doubling of capacity on each charge,” said Mr Davies. The older treatment plant is still used for one-offs, small packs, half packs and brown treating.

Meanwhile, currently a further Kallfass installation is taking place at Ransfords and will be completed in October. This is a new tray sorter process at end of the main EWD sawmill line and before the post-pointing operation. The tray sorter deals with large 6-8in square sections for gate posts and sleepers. The installation will feature automated stacking and crosscutting processes. At the moment Ransfords is using a forklift to offload items, which creates a bottleneck and items are crosscut on a small machine. “It is a huge installation and a big investment for Ransfords,” said Mr Link. The installation will improve Ransfords’ production time still further.

These large investment projects certainly show the company’s confidence for future business and there are likely to be some further spends to come, according to Ransfords. Ransfords is a single shift business with an annual sawn capacity of 50,000m3. There is no intention to increase output much beyond that, Ransfords is looking for more efficient ways of doing things. The next significant investment will be high speed edging. The current edging system was installed in 2004 and that is the oldest part of the mill now, so over the next five years that will be one the changes. It will not be an investment to drive production output but to keep Randsfords as efficient as possible and replacing what they think needs replacing. According to Ransfords they are not a business out there trying to rule the world but quietly go ahead and do their own thing!”

Longitudinal push-off destacking with automated strip stripping to remove intermediate strips.

Zero point alignment before the post-pointing station. Four circular saws point the posts on all four sides.

Kallfass radius milling cutting station for round-topping of square or rectangular posts.

Before milling, the posts are fixed in a clamping station.

Finished stacking package with pointed posts.