New restacking system eliminates bottleneck

The mechanisation specialist Kallfass was able to successfully commission the first system at Robeta Holz in Milmersdorf, Germany, at the beginning of January. What was initially planned as a more straightforward restacking plant for dried-sawn timber has become a real gem. This eliminated a production bottleneck at Robeta Holz.

“Previously, we also had to re-sort and stack the dry goods at our sorting plant. Since the demand for dry goods has risen steadily, re-sorting was only possible with considerable extra hours - sometimes the system also ran on Saturdays or we started on Sunday evening”, remembers Christian Rockel, Production Manager at Robeta Holz. This bottleneck had to be removed. Those responsible for the sawmill in Uckermark, Germany, approached Kallfass, Baiersbronn-Klosterreichenbach, Germany, with a relevant enquiry. “Kallfass has a very good name in the industry”, Rockel reasons. “We have also been approached by pallet manufacturers who said: If you cut the sawn timber with a Kallfass system, then we'll buy from you”, says the production manager and smiles. He is referring to the high accuracy of the mechanisation specialist's multiple cross-cut saw.

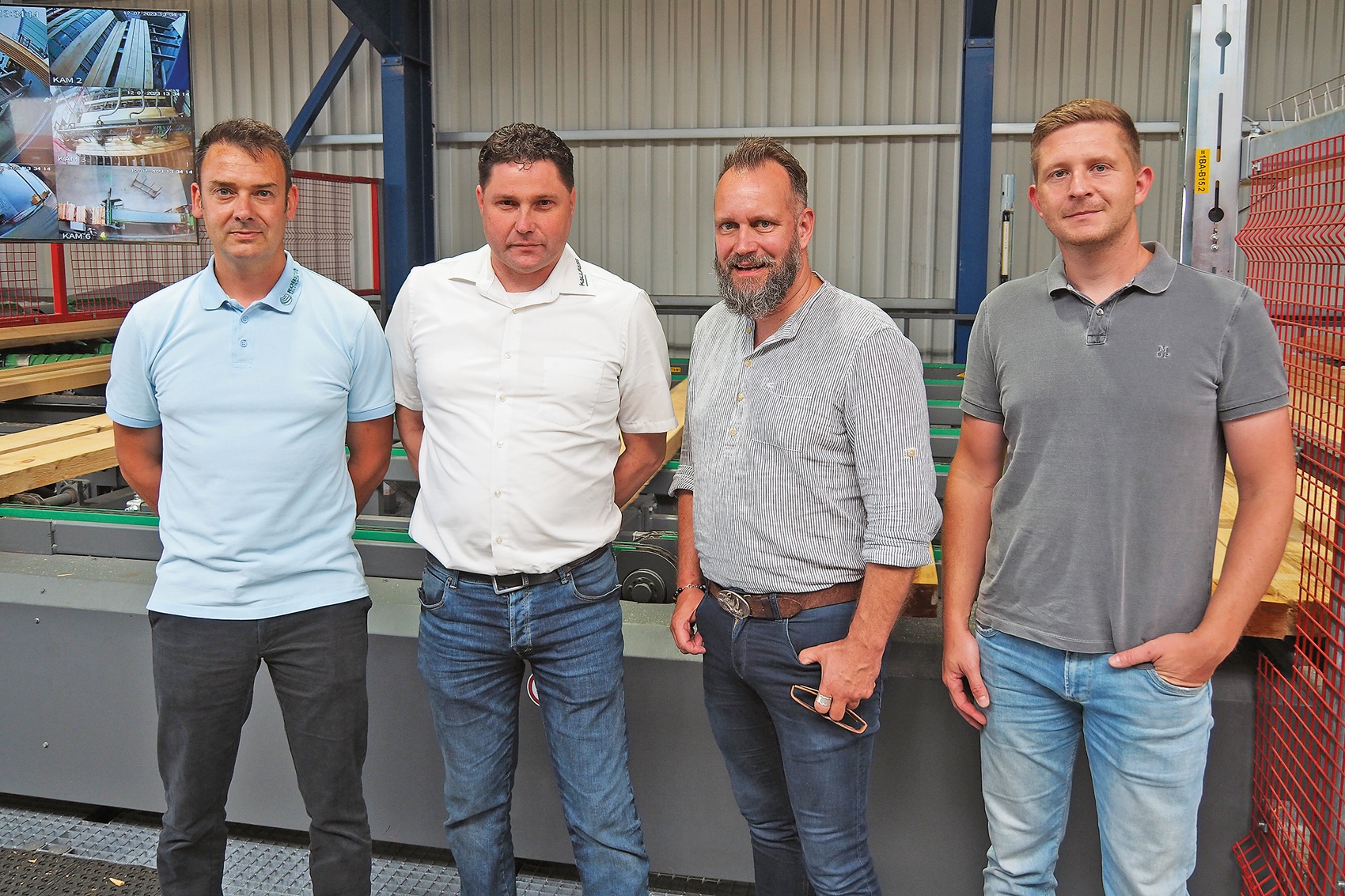

Robeta Wood Production Manager Christian Rockel with Enrico Goldhahn, Matthias Link and Rick Stille from Kallfass (from left)

Complete package instead of the “basic”

“Originally, a smaller restacking system was envisaged” recalls Kallfass Project Manager Enrico Goldhahn, and continues: “However, during the discussion it turned out that Robeta wanted to be more flexible and we ultimately delivered a fully comprehensive system with some technical refinements”. Among other things, Robeta Holz also paid attention to ergonomics: All system components are easily accessible and the walkways are particularly wide. This results in the best work conditions for the employees. “We had enough space for the planning and for the system, so we optimised the process. A great reference project has been created”, Goldhahn clarifies. His colleague Matthias Link, responsible for sales at Kallfass, adds: “All the responsible people, such as electricians and locksmiths, were involved in the project right from the start. That made the coordination much easier.”

Robeta Holz built a new hall for the Kallfass system. The assembly work started on 6 September 2022. In January, the trial operation could already begin. As mentioned, the new restacking equipment is intended for dry goods. However, Robeta Holz can also use this equipment for fresh sawn timber. The system is designed for cross-sections from 16 x 75 to 125 x 200 mm with a length from 0.8 to 6.3 m.

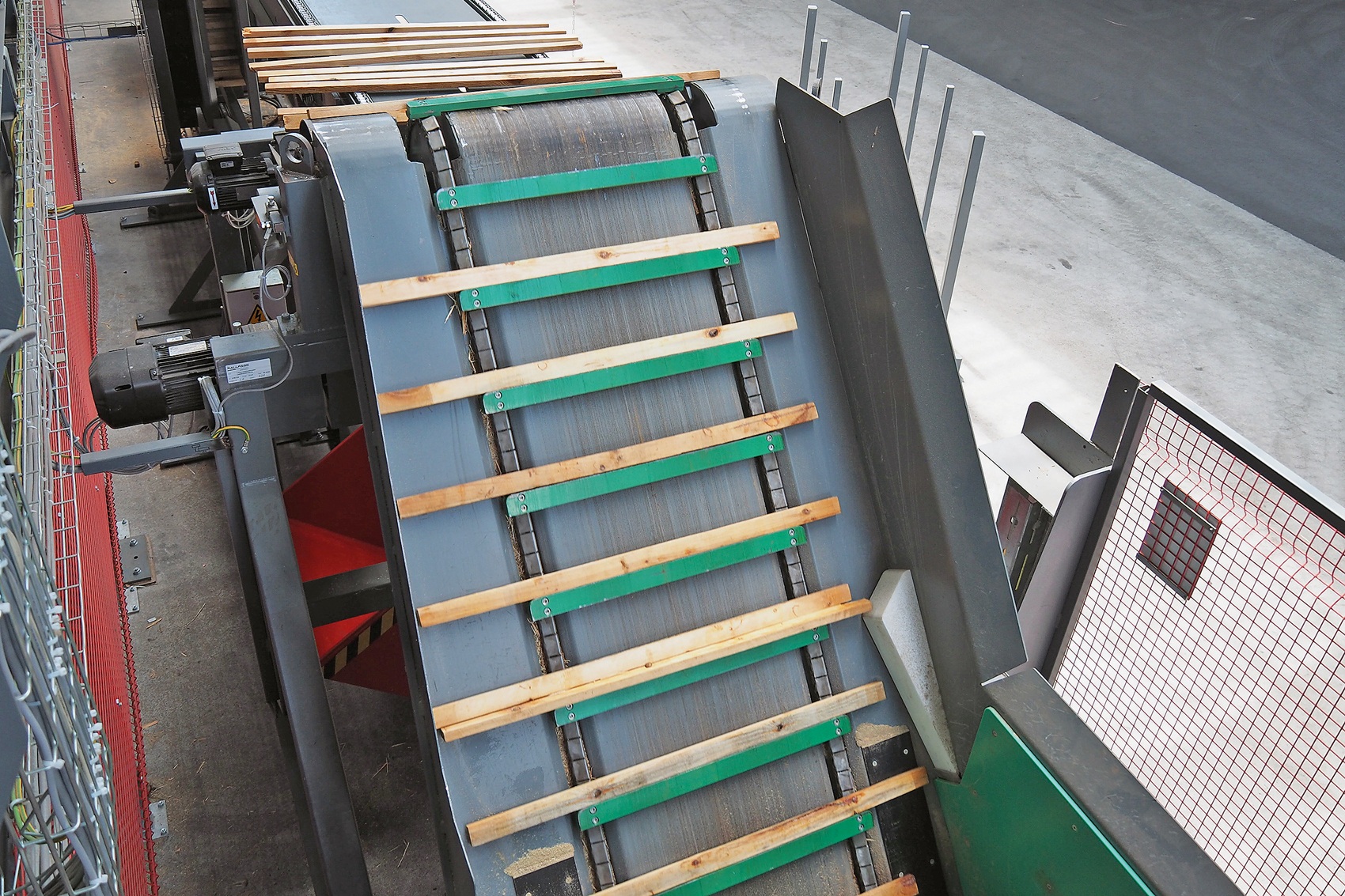

During the tilt destacking process, the layers are briefly held back (see arrows), so that the stacking sticks underneath are separated much easier and slide off.

Clean separation

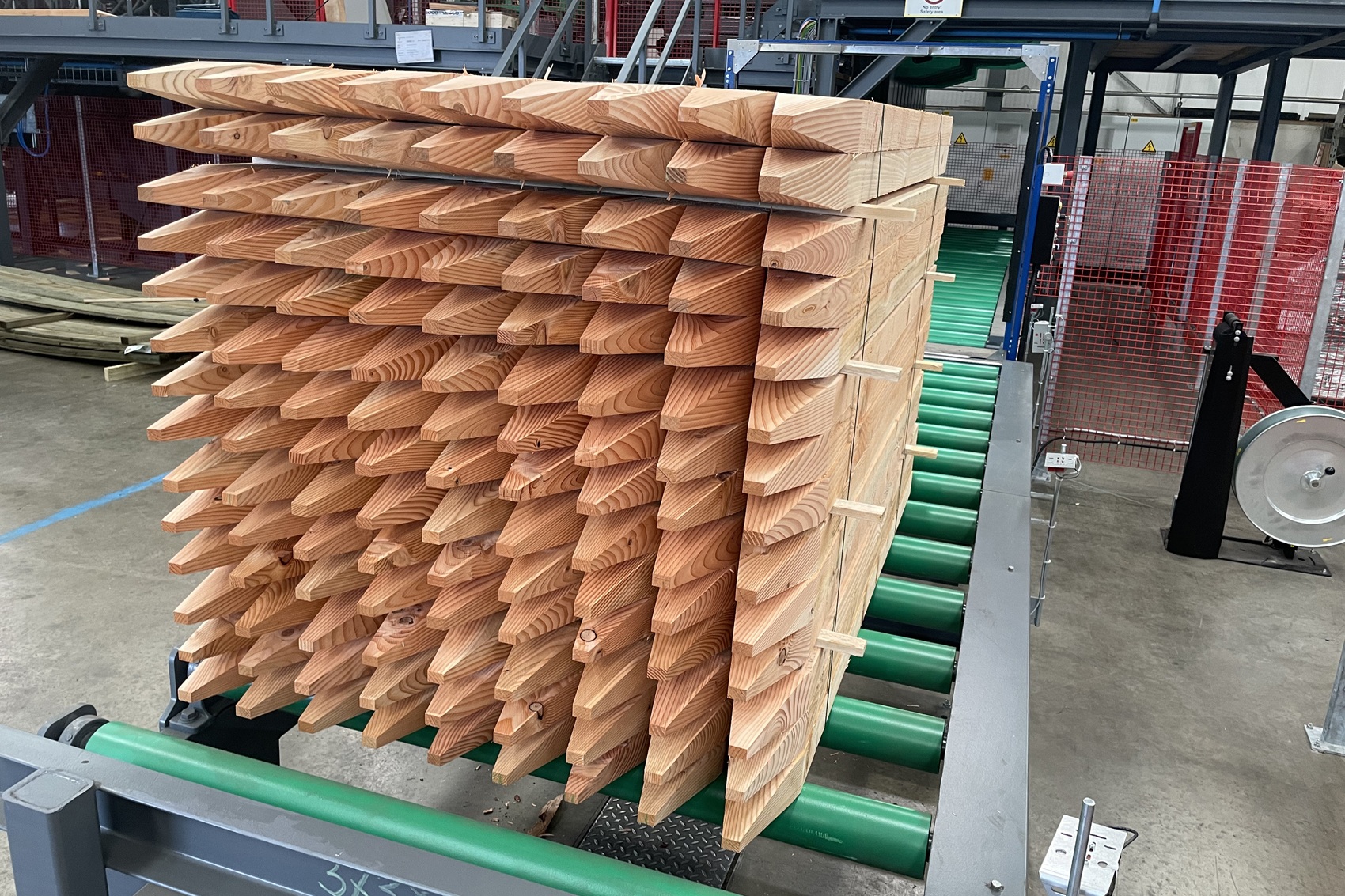

The sawn timber feed offers space for several packages. “For a higher output, the system is equipped with two conveyors”, Link explains. The hydraulic tilt destacking unit has pneumatic pawls for better stick separation. “The pine is slightly tacky - with the slight push, however, the sticks detach better from the lumber layers”, Goldhahn explains. The sticks are collected separately and space-optimised in stanchions.

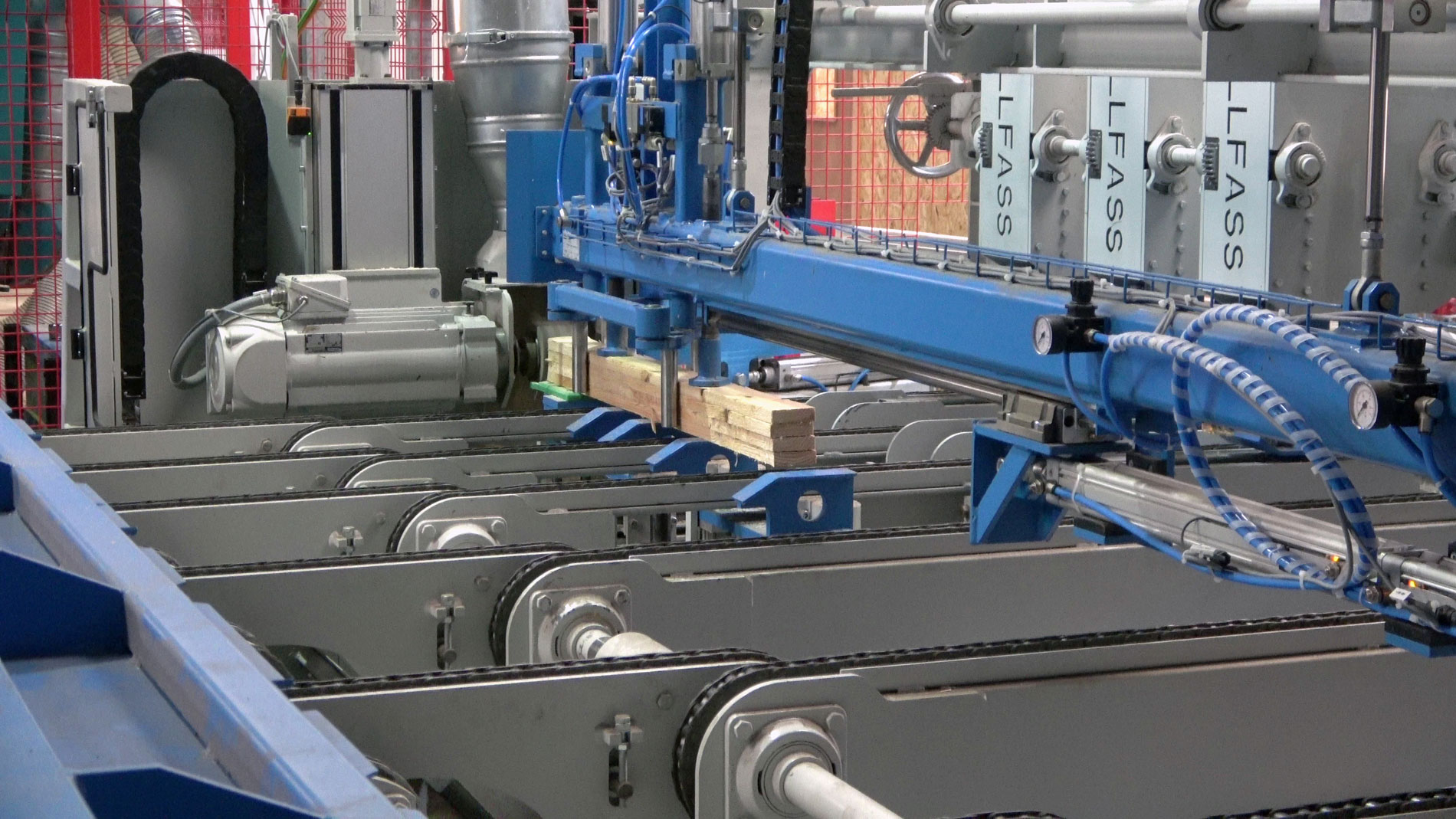

After separation and downstream of an alignment roller conveyor, the workpieces reach the assessment station, where an employee performs a final quality check. The subsequent Tongloader® cycles the boards and planks – regardless of the cross-section – onto the downstream chain conveyor at a rate of up to 120 cycles per minute. The Tongloader® is equipped with an anti-twist device. “This ensures that cross-sections that are approximately square are not transported on edge”, explains Goldhahn. The workpieces pass through the Brookhuis moisture measurement system in a transverse run-through. “Pieces that don't fit are ejected, as are the rejects”, Link points out during the tour. The respective boards drop down through a sorting flap onto a belt below and arrive at two points on a table where they can be removed separately.

Subsequently, the good parts move through the Kallfass multiple cross-cut saw. The latter is equipped with five saw aggregates – four of which can be positioned automatically.

Like a mini sorting system: The sticks in the tilt destacking unit are removed, separated and collected in stanchions in a space-optimised manner.

Adjustable magazines

The stacker has a capacity of up to 12 layers per minute. Kallfass has further strengthened this stacker for large wood dimensions. The system has eight double magazines for stacking sticks and sticks being disposed of. “The magazines can be positioned automatically. This also allows more sticks from a magazine to be placed on the sawn timber layers if required. The motorised adjustment allows the sticks to be positioned closer to the cutting edge. The minimum distance corresponds to a stick width plus 10 mm”, Link explains and adds: “We have also equipped the existing sorting system with these new stick magazines.”

The finished packages arrive at the Kallfass automatic foiling station. “This station can also be equipped with unfolded film up to 3.6 m wide”, informs Link. The wrapped packages then enter the Fromm package press with two squared timber magazines, are strapped and transported out of the hall through a high-speed door. The parcels are transferred to the pick-up point for the stacker via an angular transfer device.

“Kallfass has done a very good job. The cooperation was impeccable – the handling of the installation was also smooth due to the good planning”, reports Rockel. “We can now respond to customer requests much faster and have brought the working hours back to a normal level. The system is operated by three employees and one forklift operator. The output of the system is very high, consequently requiring only a single-shift operation. I am happy every day about the successful project”, says the production manager, visibly satisfied.

The stacking unit is equipped with eight double magazines - these can be moved and positioned exactly at the cutting edge.

"I am happy every day about the successful project"

- Robeta Wood Production Manager Christian Rockel -

After the lumber has been separated, an employee can inspect the timber manually.

After the Tongloader® and the layer formation, the sawn timber reaches the multiple cross-cut saw from Kallfass which consists of five saw aggregates.