The Swedish company Åsljunga Pallen decided to invest in a new sorting system and stacking line in order to increase the sawmill's output and level of automation at the same time. Kallfass was chosen as the supplier. The mechanisation expert used all his expertise to harmonise the customer's requirements with the available space.

Åsljunga Pallen from Örkelljunga in southern Sweden specialises in the manufacture of pallets and packaging goods. The company produces around 7500 pallets a day. The sawn timber required for this comes from their own sawmill. Around 60,000 m3 of sawn timber is produced there every year, 99% of which is processed in-house. “This makes us one of the largest pallet manufacturers in Sweden”, reports Stefan Nilsson, owner and managing director of Åsljunga Pallen. The pallets are sold to customers in Sweden and Denmark within a radius of around 300 kilometres.

Best solution offered

Sorting the side goods was the bottleneck in production. “The quality control was done manually - that was very time-consuming”, explains Oscar Elzén, Production Manager at Åsljunga Pallen. For this reason, the decision was made to invest in a new sorting and stacking line from Kallfass, Baiersbronn-Klosterreichenbach/DE. As part of these conversion measures, the company also expanded its sawing line to include a resawing machine from EWD. "This means that it is now possible to cut the entire log to size for our pallet production”, the production manager continues.

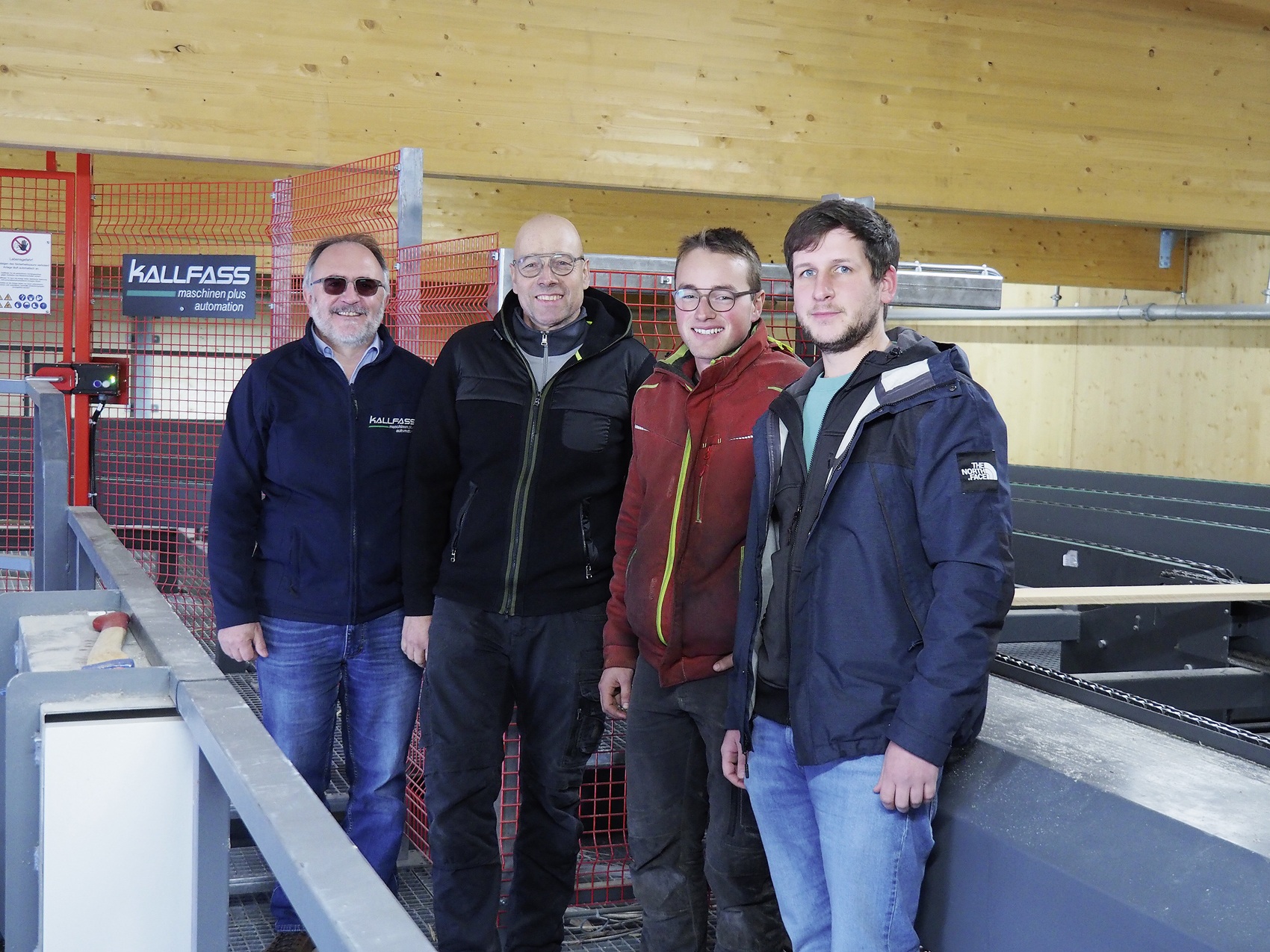

“Kallfass understood how we work and which process is best for our plant, and offered a technical solution for our requirements that we liked”, explains Nilsson, who is the third generation of his family to run the company.

Space and time - two challenges

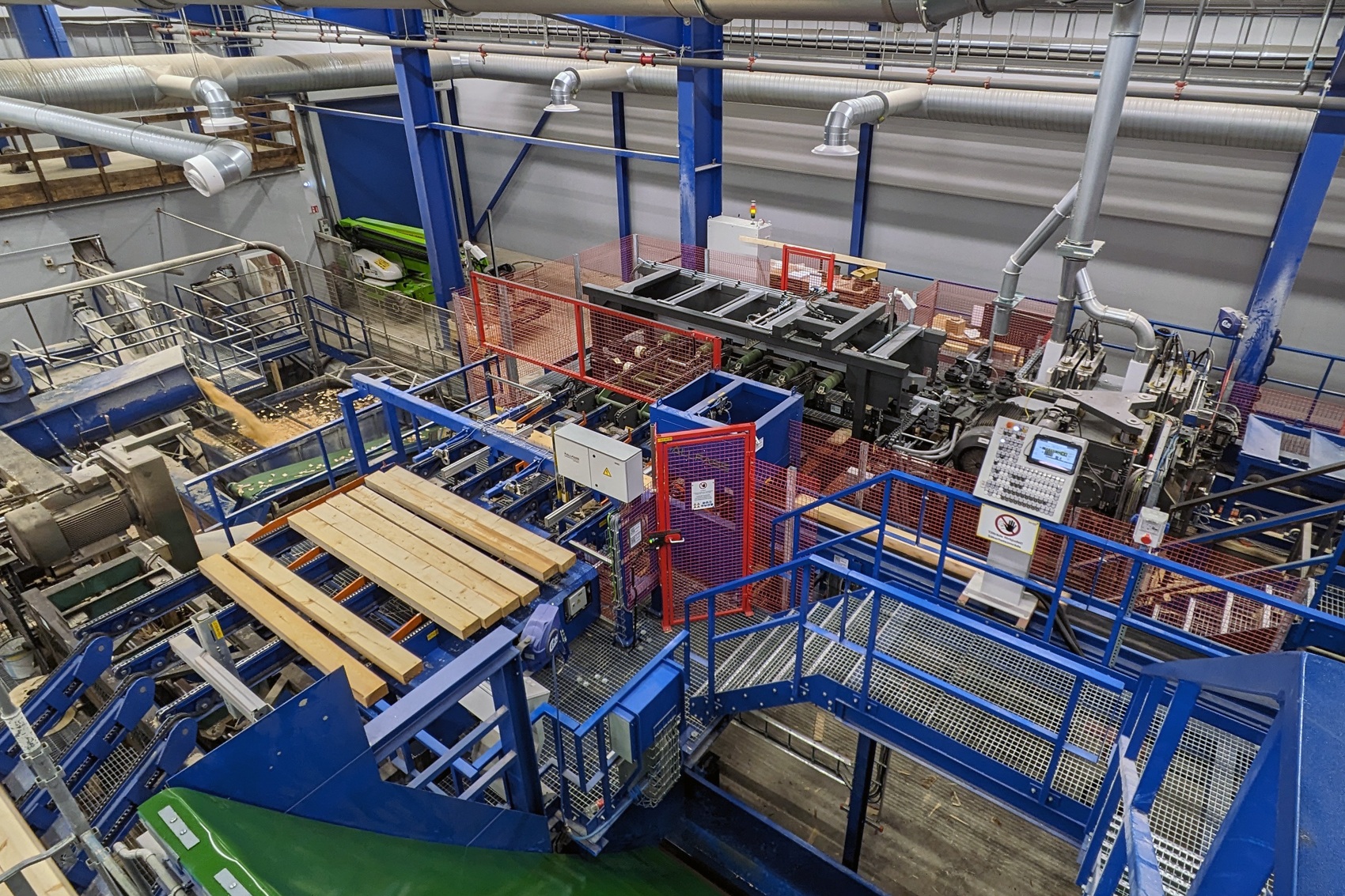

The building in which the new sorting and stacking facility is housed dates back to 1956. This has recently been expanded somewhat. “However, we had to make do with the available space for this extensive project and utilise every millimetre”, explains Dominik Hauser, who supervised the project on behalf of Kallfass, with a grin: “During installation, there were even bets as to whether the robot would actually have enough space for its intended function without having to make any adjustments to the building. To the detriment of some sceptics, however, the robot was commissioned as planned”. He is referring to the robot that is responsible for automatically filling the moulding magazine. But more on that later.

In addition to the available space, there were other points to consider: Initially, a large part of the installation was carried out during ongoing operations. “We only had six weeks of downtime”, Elzén informs us. And the roof must not be opened during installation. “Thanks to the cooperation of everyone and the high level of flexibility on the part of Kallfass, we were also able to master this”, says Nilsson and is very satisfied with the mechanisation specialist's handling. Assembly began in March and the sorting system for the main and side products has been in operation since the beginning of August.

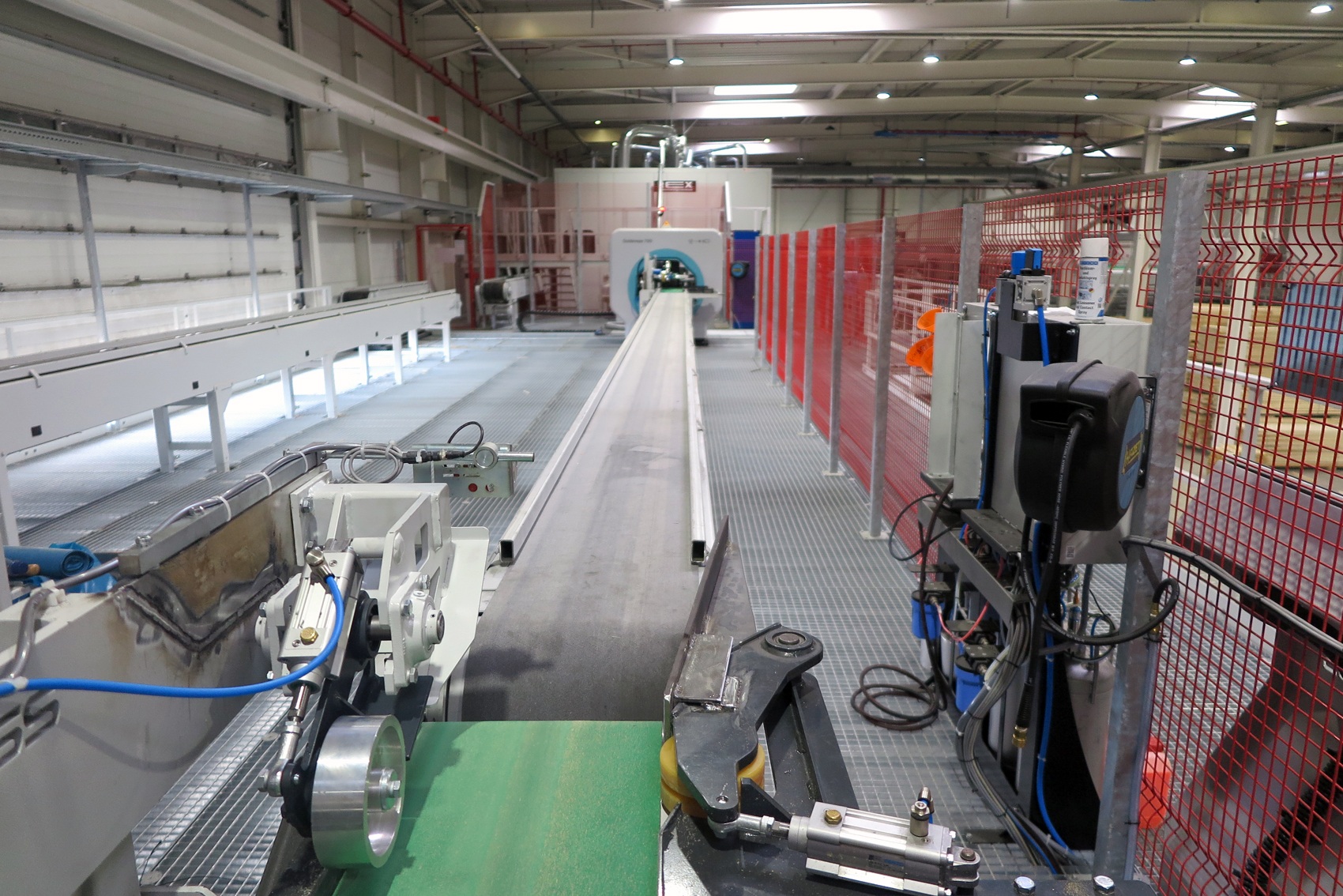

To make optimum use of the space, the Kallfass concept has several level changes.

“Kallfass understood our processes and offered us the best technical solution. We anticipate an increase in production of at least 20%”.

- Stefan Nilsson, Managing Director Åsljunga Pallen -

Complex mechanisation

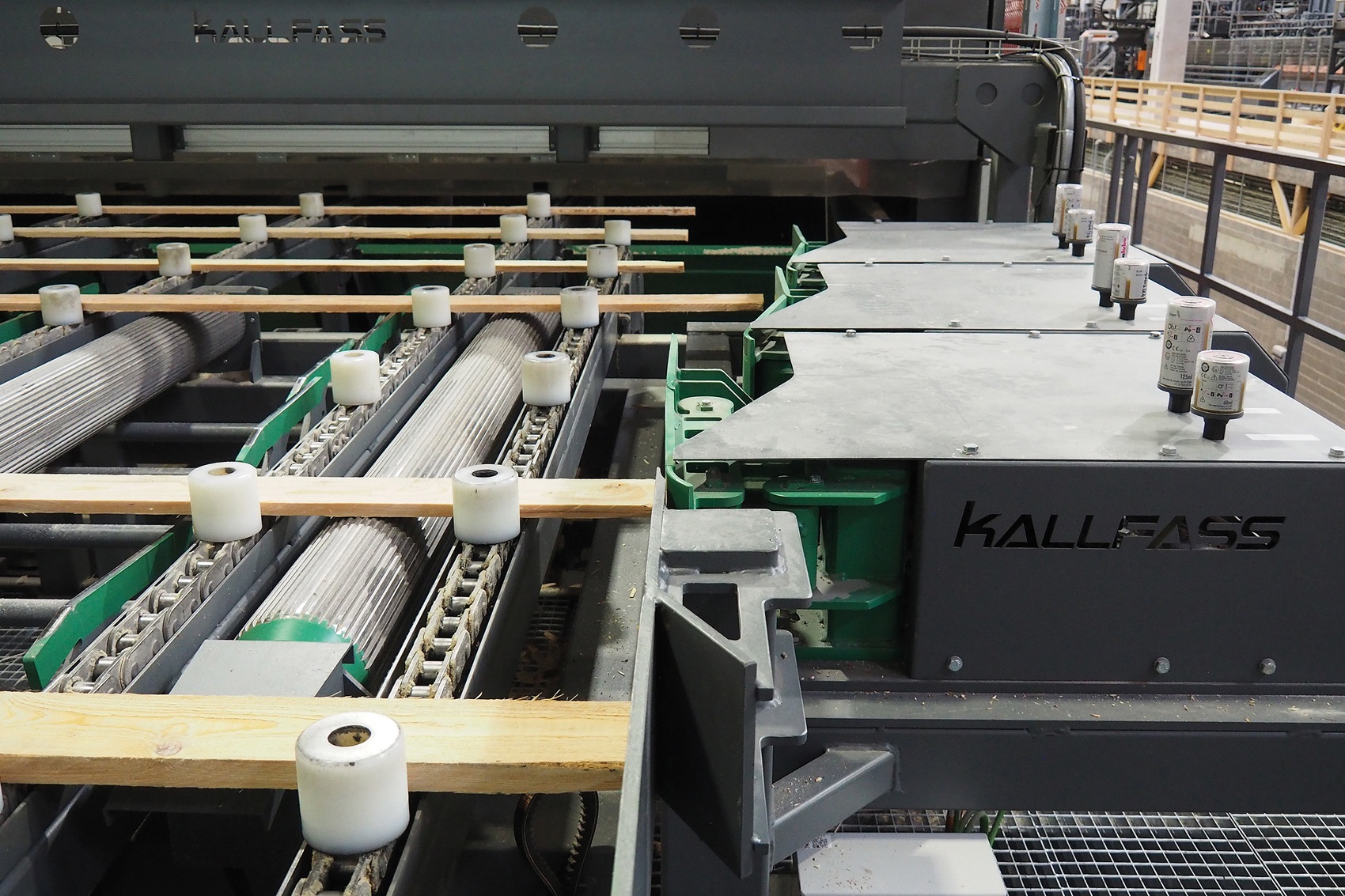

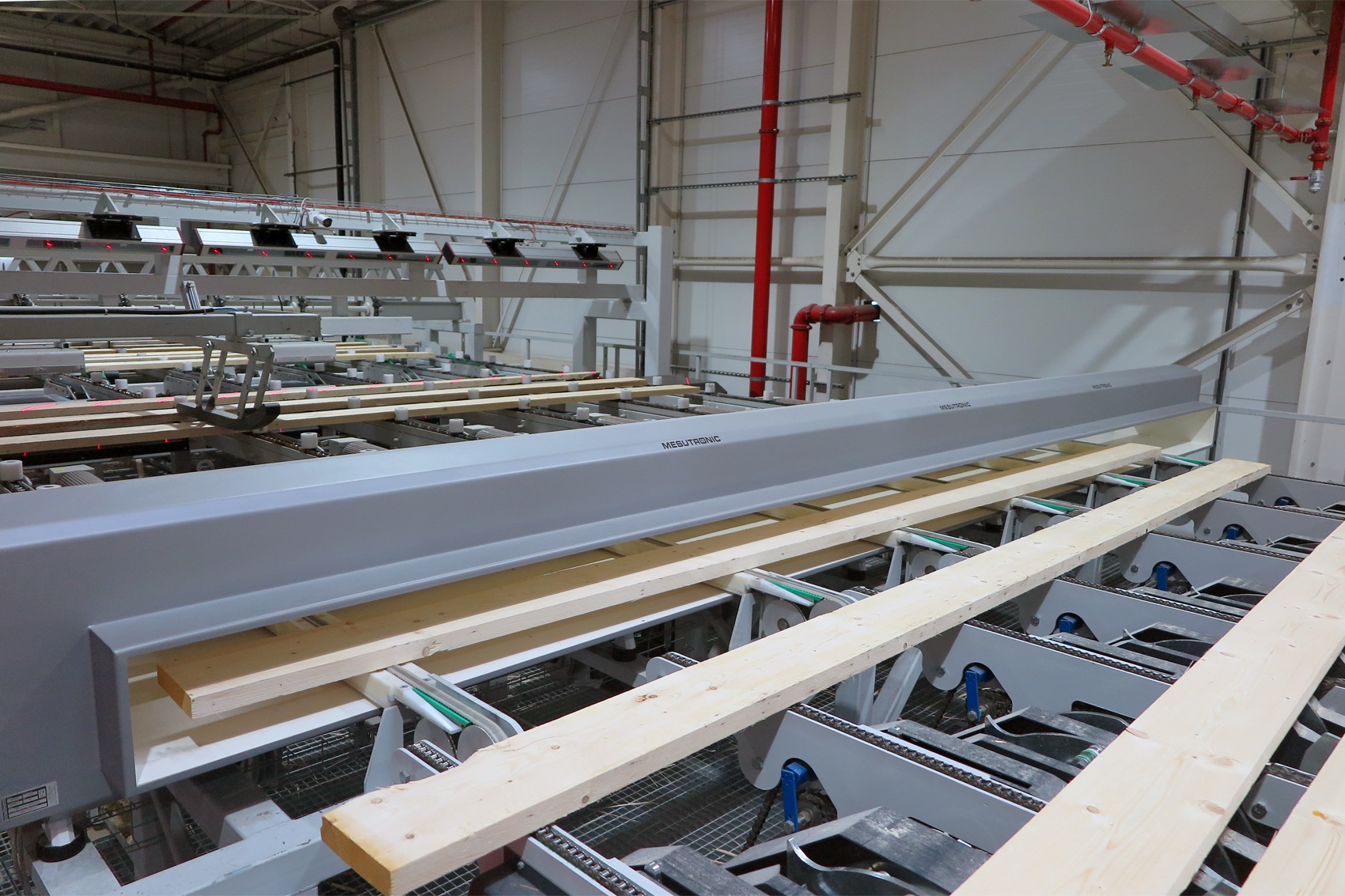

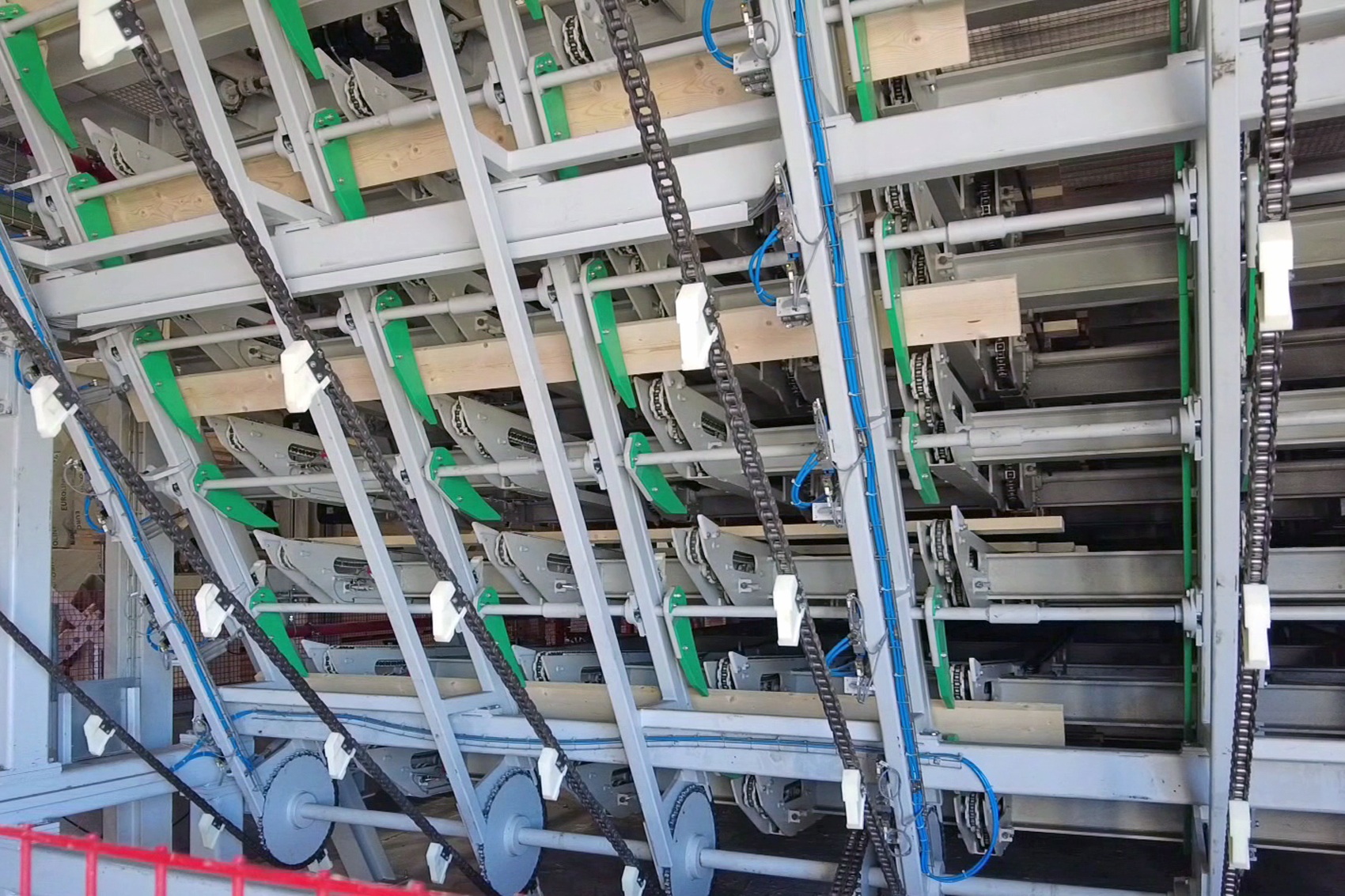

Kallfass supplied the mechanisation with transverse take-off, rising diagonal conveyor as well as cycle-in and thickness measurement between the existing sawing line and the new EWD resawing machine. “Before the resaw, there is the option of transporting the main product to an existing stacking system via an automatic take-off device, depending on the dimensions, output, adjustment or maintenance work on the main line”, explains Hauser. In addition to a direct side product infeed, a stock edger is located under the new main product infeed to the resaw, which also feeds the boards for sorting. Each of the three feeders has its own buffer level. “The main goods are buffered on one deck and the side goods on two decks. When a floor is full, it is emptied automatically so that the sawing line does not come to a standstill”, Hauser explains. A level changer takes the boards to the top. The goods are first aligned there before the Tongloader cycles them into the carrier conveyor at a rate of up to 120 parts per minute. There is also the option to cut back at zero line.

View of the feeding of the main product to the resaw machine.

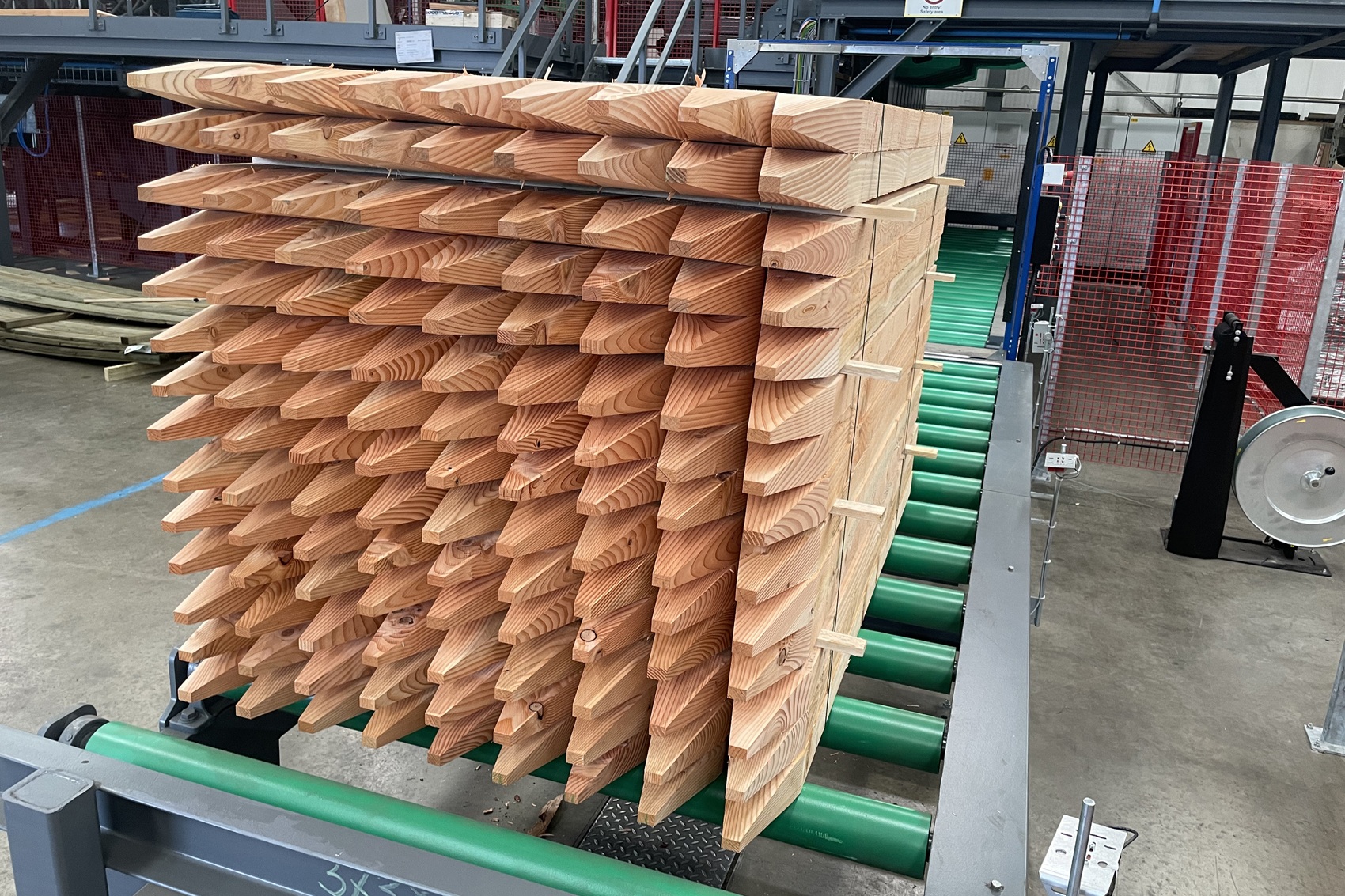

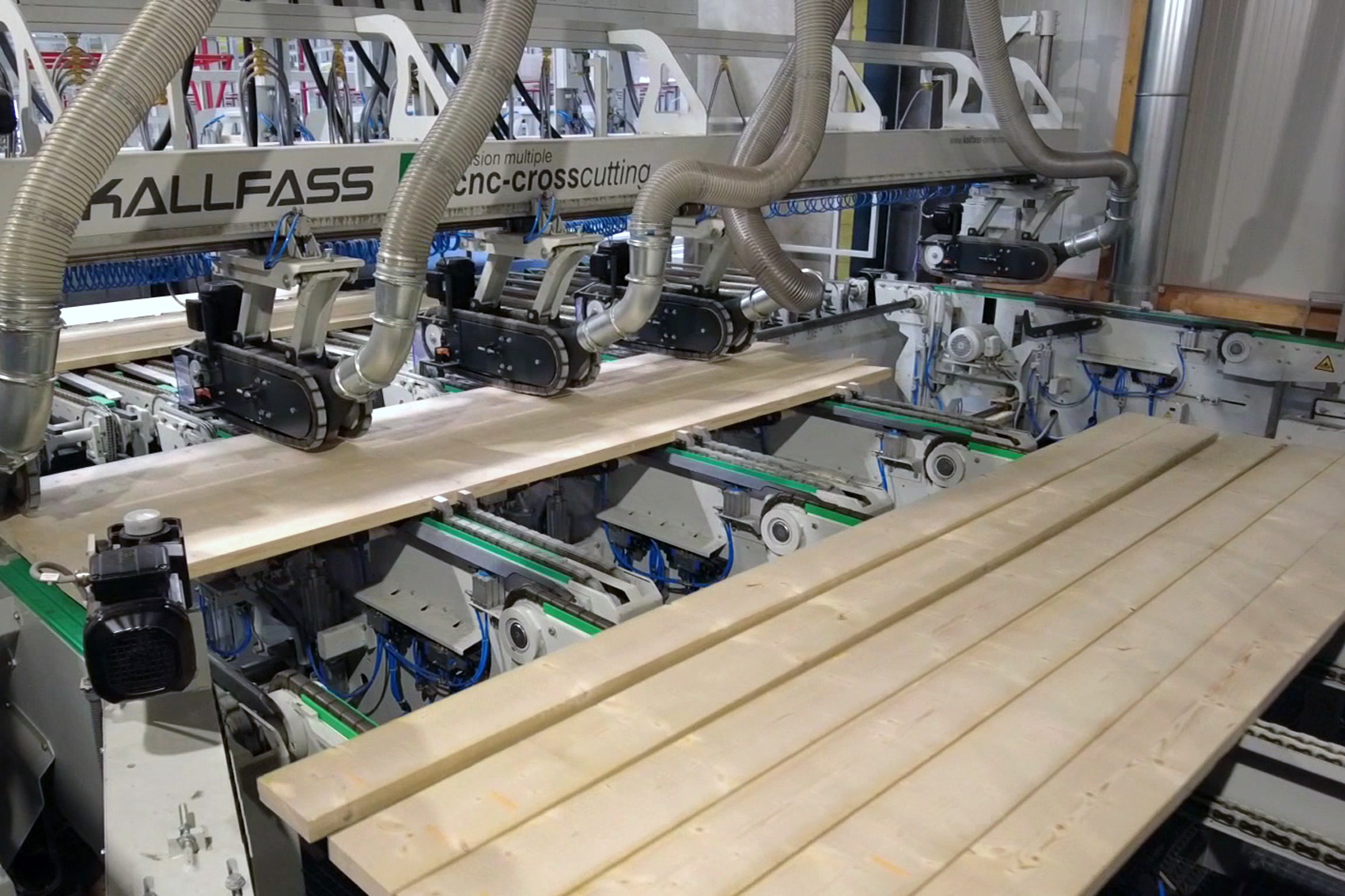

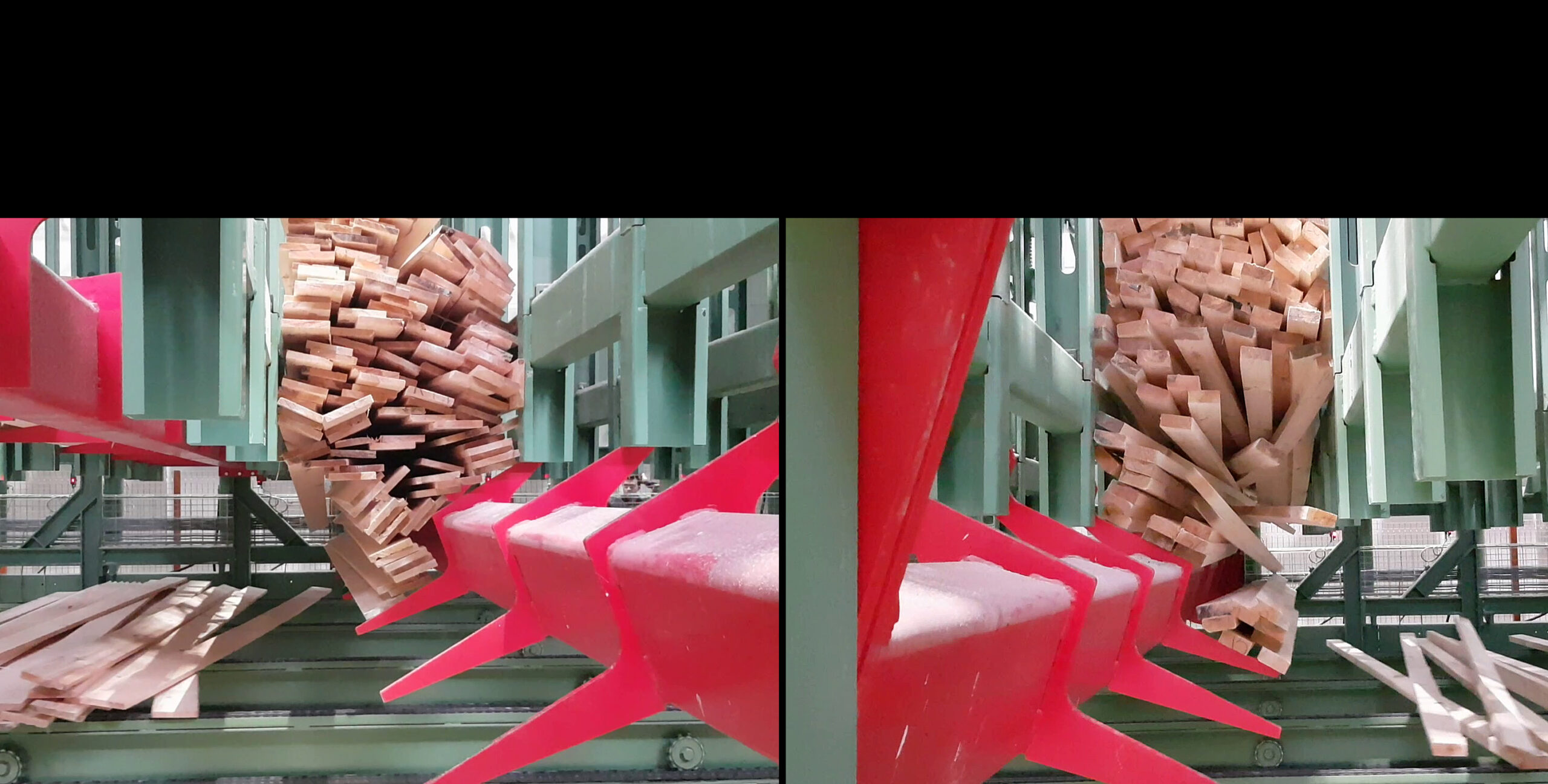

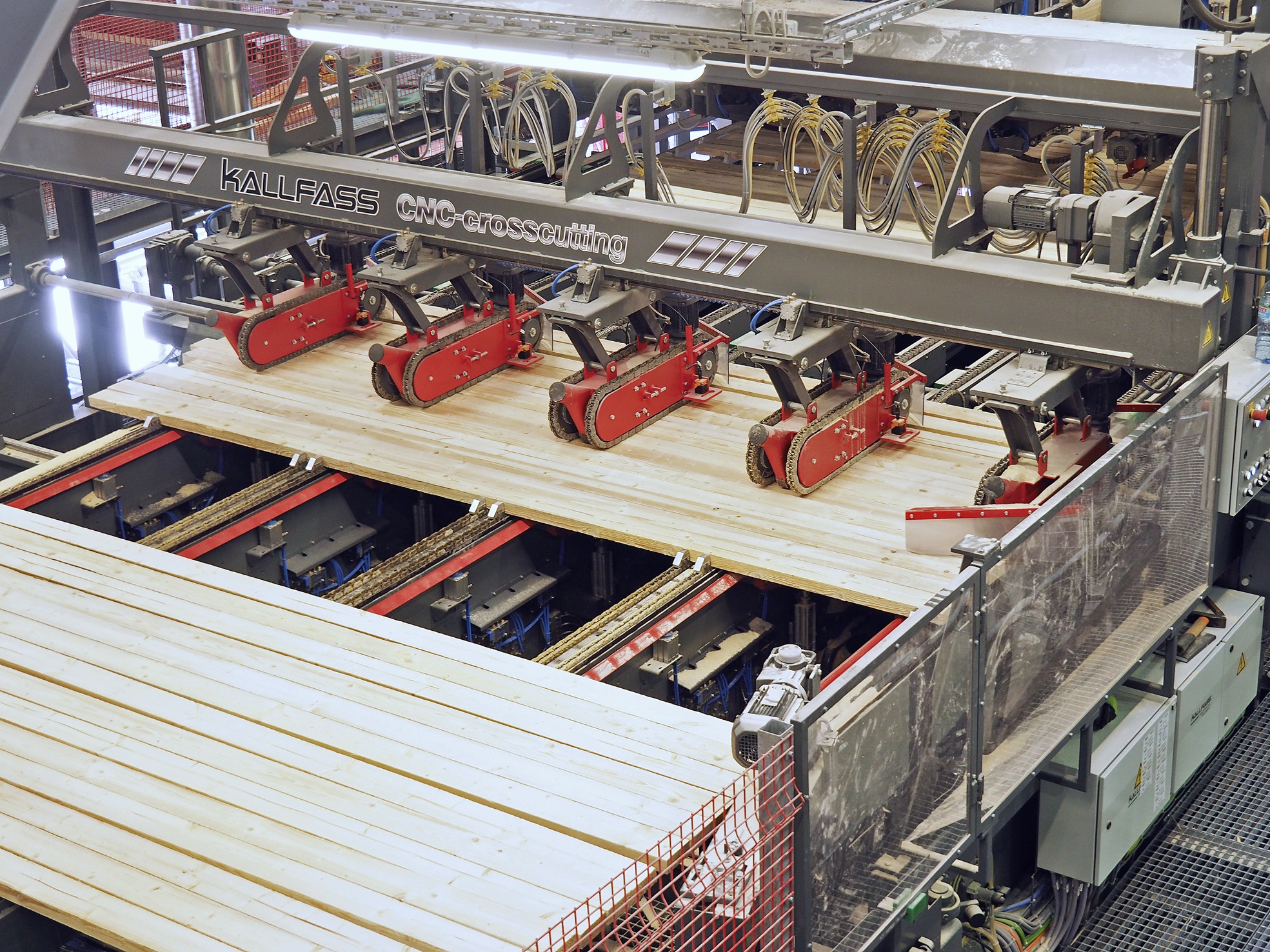

After another level change downwards, a Microtec scanner recognises the wanes and gives each board the corresponding quality or dimension. These are then placed in one of the 15 vertical boxes. The boxes are emptied downwards onto a chain conveyor, which transports the box contents further onto a traversing chain conveyor feeding the timber to the parallel stacking system. “This solution was also due to the space available”, says Hauser. A step separator and an unscrambler transfer the boards to another cross conveyor for layer formation. The Kallfass project manager estimates their output at up to 14 layers per minute. The downstream multiple cross-cut saw from Kallfass is equipped with four saw aggregates - three of which can be positioned automatically. The layers of boards are then transported to the stacking machine, which has six magazines with automatic strip placing.

High degree of automation

The robot mentioned above fills the stick magazines. Kallfass installed an automatic feeding system for this purpose. A forklift driver places the stanchions filled with sticks onto a conveyor, from where they are fed into the system. Two different types of sticks can be fed separately via a hoisting unit. After the stanchions are emptied, the sticks are fed to the scanner via a step separator and unscrambler. The scanner checks the timber for dimensions and damage. Unsuitable sticks can be automatically ejected. This is followed by the formation of bundles, so the robot can grip several strips at once and fill the magazines. Kallfass also supplied the automatic pallet feeder for the stacking system. The number of pallets required can be determined according to the length of the timber. The empty pallets are automatically removed from the magazine and pre-positioned so that the pallet is always in the centre of the workpiece length. The layers of boards are then automatically stacked on pallets. The maximum stacking height including pallet is 1.9 m. Hauser specifies a target output of up to 90 packages per day.

Kallfass supplied an automatic stick feeding system to ensure a high degree of automation …

... and a robot for filling the magazines of the stacking system.

Thanks to the high degree of automation, Åsljunga Pallen is able to operate the entire sorting and stacking line with just two employees. “We are currently carrying out the final optimisations. Then we expect an increase in performance of at least 20 per cent”, says Nilsson.

Feeding the side material to the wane scanner.

Visual assessment of the goods before the multiple cross-cut saw.