With 29,363 visitors and 523 exhibitors, this year's EUROBOIS broke all records, according to the official statement from the trade fair organisation. Kallfass and their French sales partner V.B.I SARL Bleesz International were also pleased with the large number of visitors to the joint stand in Hall 5.

EUROBOIS in Lyon took place in February this year. From 3 to 6 February, the fair opened its doors to the wood industry's experts. From log cutting to sawn timber processing and interior woodworking, visitors were able to find out more at the stands of numerous exhibitors, including some international companies, which held a 31 % share. Fortunately, the statistics show an increase in visitor activity in all areas. Eurexpo quotes figures of +77.83 % in interior woodworking, +114.18 % in frame construction and +41.37 % in sawing and sorting.

France is important export market

Kallfass has also experienced the increased interest in sawing and sorting systems. For the mechanisation specialist and manufacturer of multiple cross-cut saws, sorting and stacking systems, the French market with its many family-operated sawmills is an important export market. In the last three years alone, nine extensive projects have been realised in France, including several sorting systems as well as complex cutting, stacking and packaging systems. Three further projects are in development. The French sawmill operators appreciate the high precision of the Kallfass systems and our ability to design an optimal mechanisation solution for the respective production situation.

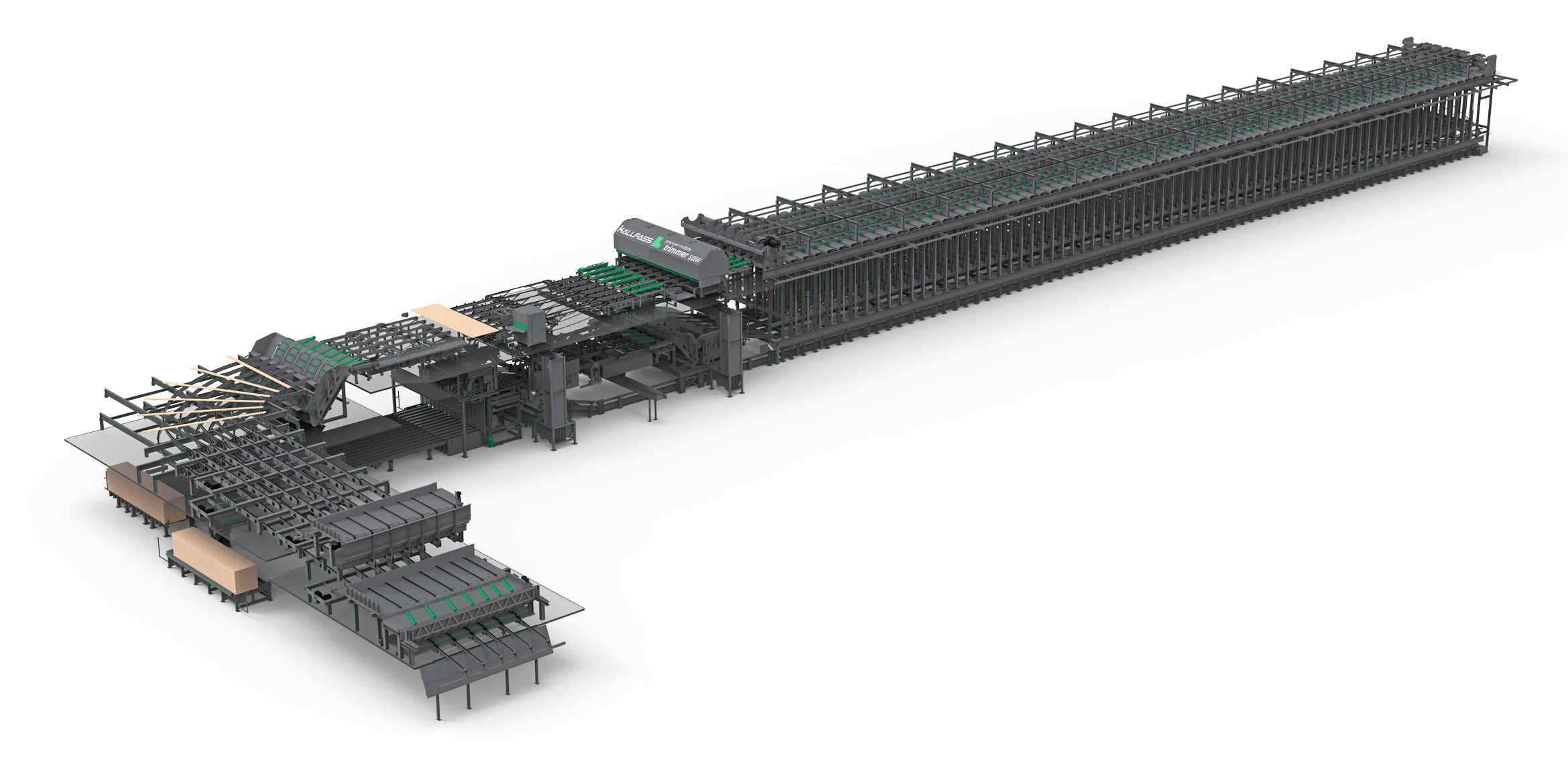

Kallfass sorting and stacking plant for main and side products in a French sawmill

In V.B.I Bleesz, which is celebrating its 20th anniversary this year, Kallfass has a competent partner at its side who knows the French market and its requirements. Among the numerous visitors to the EUROBOIS stand were many existing customers as well as some new business contacts. Hans Haist, Kallfass Managing Director, who is responsible for sales in France, will be travelling extensively over the next few weeks to turn discussions into real projects.

Positive visitor response at EUROBOIS

The EUROBOIS trade fair team

Copyright et crédits photos PIX'L AGENCY