A&J Scott has made its secondary/value-added production automatic with the addition of a new line by Kallfass. A&J Scott MD Robert Scott tells Stephen Powney how the investment has revolutionised its operations.

Long established family sawmilling company A&J Scott was one of those timber industry businesses which kept operating right through the Covid-19 lockdown period. Based in Alnwick, Northumberland and with an extensive product range which is heavily focused on fencing components, landscaping and garden products, the company has experienced huge recent demand. Recent significant investment in technology – an automatic value-added product line from Kallfass – has helped service the demand during this unique period.

“We managed to keep working two shifts right though the whole period, including the initial 2-3 week lockdown period when it appeared quite bleak for many people,” said Robert Scott, managing director of A&J Scott. “We only dropped two shifts in total when we had a bit of self-isolation.” The sawmill ran at about 75% for a couple of weeks initially and was up to normal speed within a couple of weeks. “In the main it has been good. The fencing and landscaping sector has been very busy, so I feel we have capitalised on it as best as we could. The demand has been insatiable since April and we have been struggling to keep people satisfied with timber.

“It’s been a perfect storm, you had a lot of people sitting at home on 80% pay, mortgage holidays, not having to work but they can’t go anywhere, they can’t go to the pub, there is no sport on and they’re sitting looking at the fence which probably blew down in February. They’ve all taken the decision to invest in the garden which is great.” The decision of some other mills to shut for a period also opened the door to new customer conversations for A&J Scott. “We have a far greater customer base then we did prior to this episode. So, it’s been a difficult but overall positive experience.”

Investment with Kallfass

A&J Scott has a primary sawmill line – (hybrid of Soderhamn Eriksson and Brodbaek technology) for cutting small to medium sized logs and another line (EWD) for cutting the oversized logs. The new Kallfass line installed in May, 2019 is focused on secondary processing.

“We had quite a sprawling, manually-operated secondary processing department which over the years had grown arms and legs and consisted of lots of small machines across the site,” said Mr Scott. “We wanted to consolidate it and upgrade the machinery in the process. Essentially the aim was to increase the volume of wood processed per hour per person – which we have done with the Kallfass line. We have also improved health and safety / environmental provisions and future proofed secondary processing/value-adding for the next 10-20 years.”

Conversations started between A&J Scott and Kallfass three years ago and included some visits to Kallfass customers in Germany and Holland, as well as several visits to Alnwick to find a solution to automate the mill’s secondary production processes.

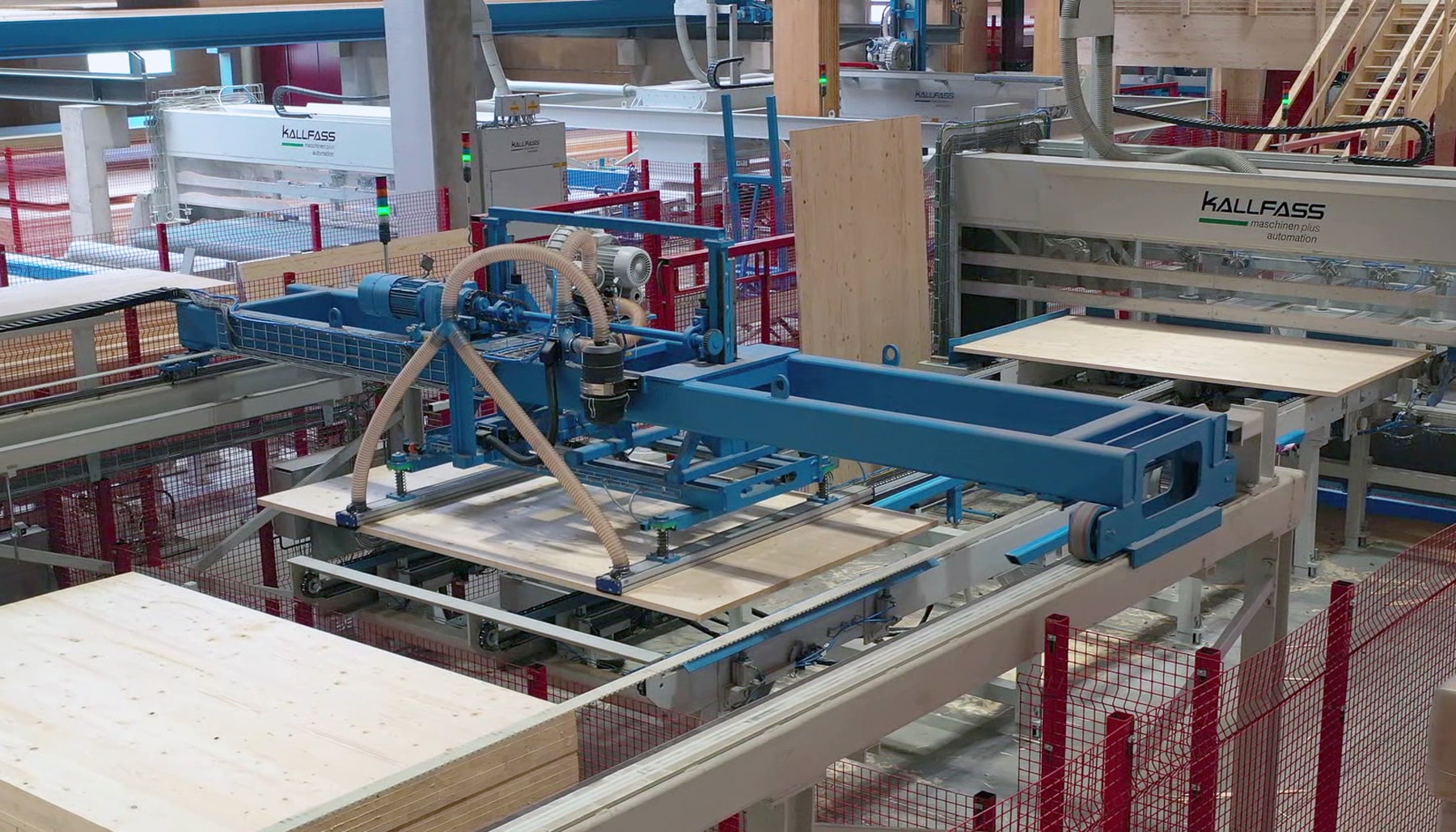

“We looked at what was available in the market,” added Mr Scott. “We deemed the Kallfass solution and the equipment to be the best and chose them as our supplier and further developed the project with them.” A&J Scott had not previously worked with Kallfass as a technology provider – Kallfass was the turnkey technology partner for the project. “We designed the line, integrated the different machinery and also installed the complete line in the building,” said Matthias Link, Kallfass sales manager.

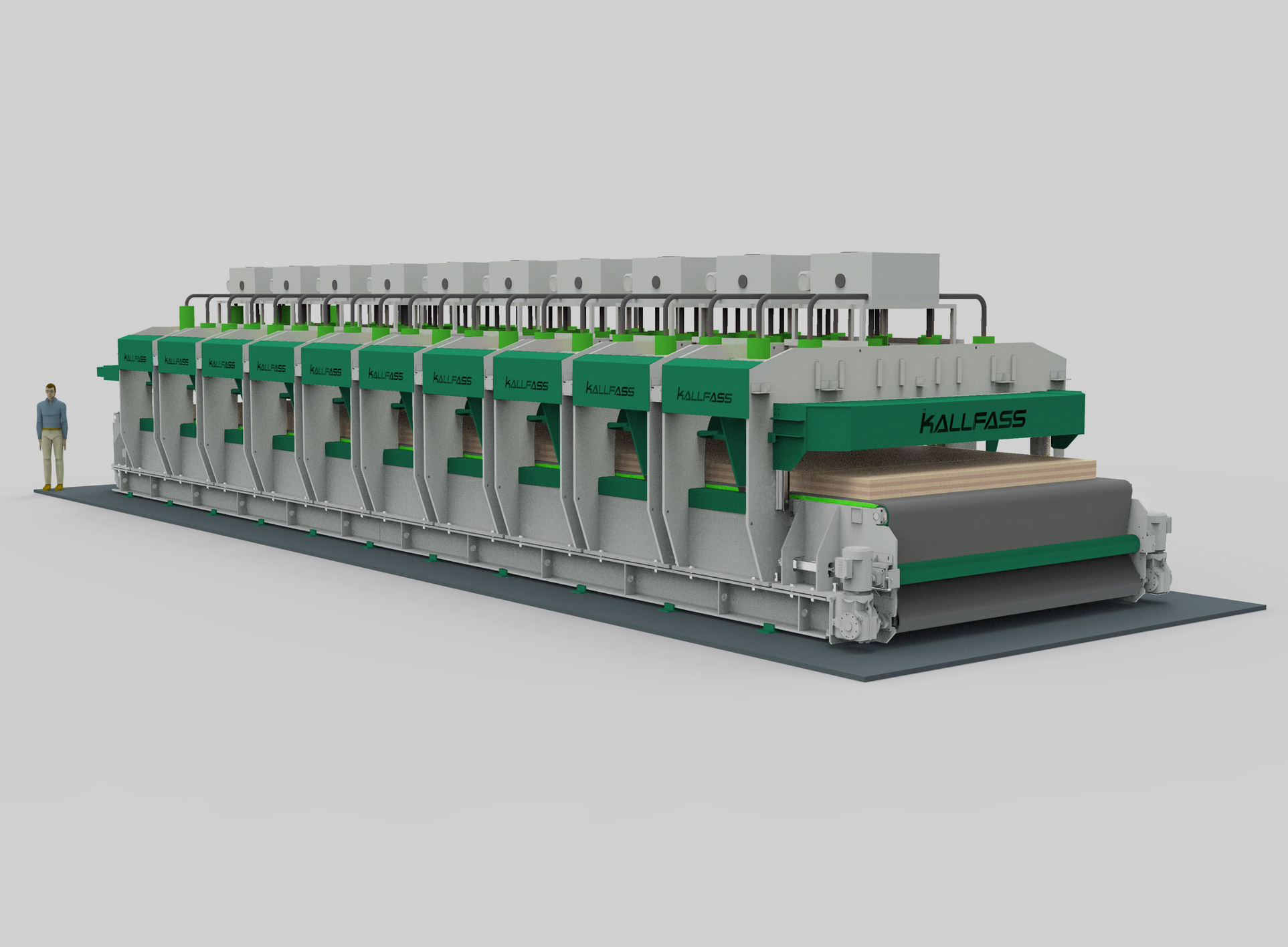

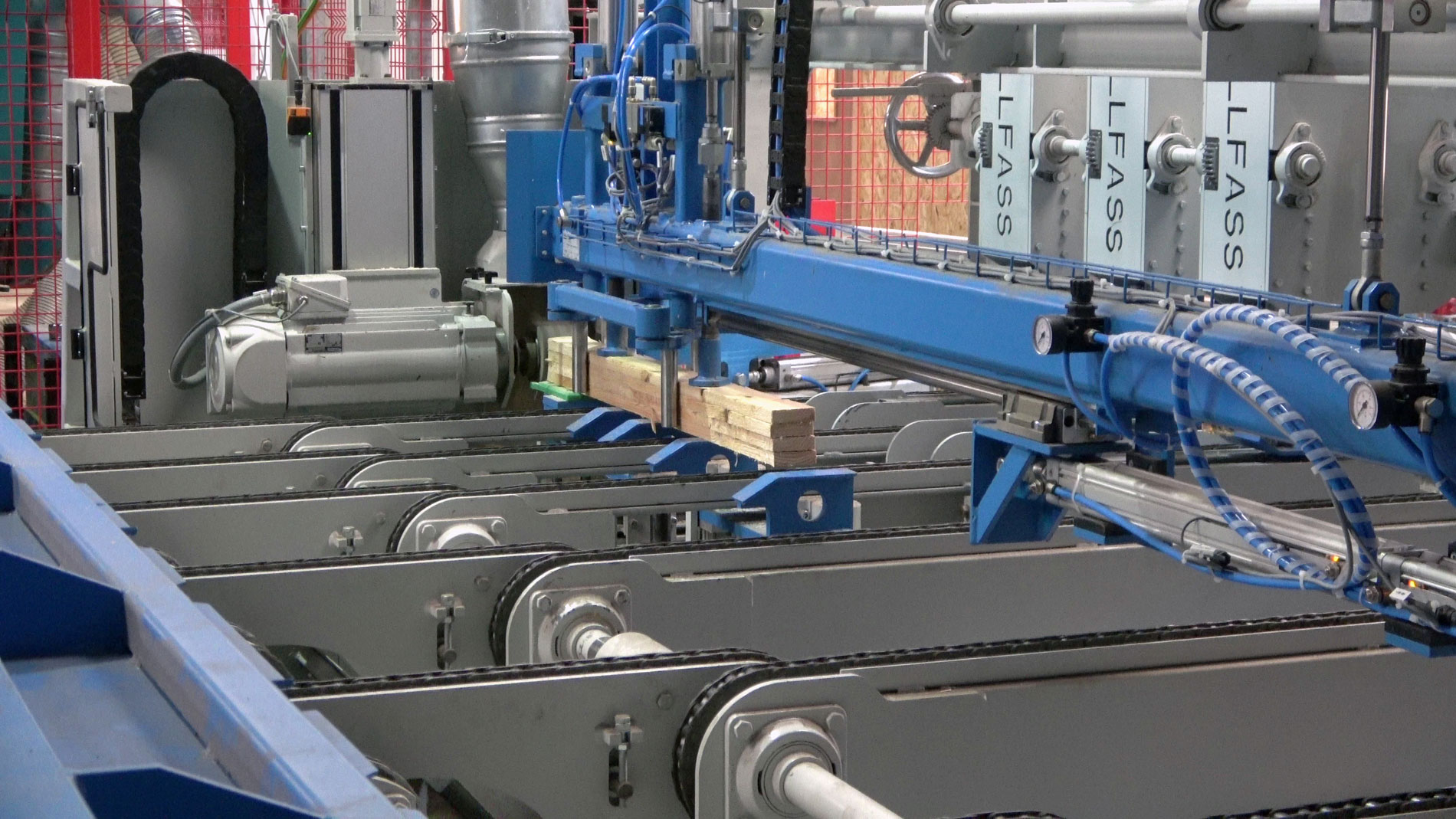

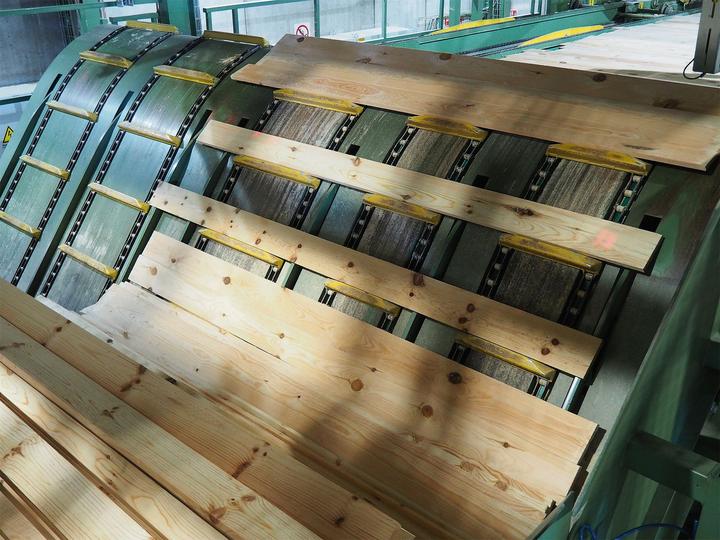

Kallfass technology included cross-cutting, strapping, pointing, round-topping, stacking and destacking. It also integrated an existing resaw, a new Rex planer, Mosca mini-bundling and a Fromm bundling system. The cost of the entire project was in the region of £4m and installation took about six months. All work steps for the manufacturing of fencing products are now integrated in one fully automated production line in a confined space. The line process starts with a forklift truck feeding the line with raw material ranging from 800-4900mm in length, 75-250mm in width and 16-200mm in thickness. This is followed by destacking, cross-cutting to length, post pointing, radius trimming of fence boards, resawing of single parts/cants, singling out and planing, mini bundelling and multiple crosscutting and stacking/strapping.

“We have an extensive range of everything from a 450mm 50x50mm peg which is 4-way pointed to a piece of decking and everything in between – panel battens, featheredge boards, panel cappings,” added Mr Scott. “Everything we produced up until the installation for the Kallfass line we did on smaller machines so the idea was to consolidate, take out those smaller machines, upgrade and also build in some extra capacity as well.”