The British company Charles Ransford & Son has been pursuing its consistent investment strategy for years. However, the primary goals of the modernisation are not an increase in production but an increase in production efficiency as well as the degree of automation. Kallfass was able to deliver two systems last year that are equipped to do just that.

Charles Ransford & Son is located in Bishops Castle—about an hour and a half’s drive west of Birmingham, England—where, among other things, the company focuses on manufacturing fencing and landscaping products for the domestic market. In its in-house sawmill, where Douglas fir, larch and spruce are processed, the company’s 58 employees produce around 55,000 m3 of sawn timber. The company has invested more than €22 million in further development in recent years. In 2022, two projects—a layer sorting system for long cross-sections and a post-pointing system—were successfully completed when the system specialist Kallfass from Baiersbronn in Germany, was commissioned. “When we made the investments, we first and foremost wanted to add to our productivity, not necessarily our volume”, explains Craig Leitch, Purchasing Director at Ransford. “Having the two new Kallfass systems, we can now respond more quickly to orders, improving our customer service in today’s challenging market. In addition, we have been able to add a seven-fold increase in our production output”, adds James Davies, Mechanical Engineer at Ransford.

A confident, long-standing partner

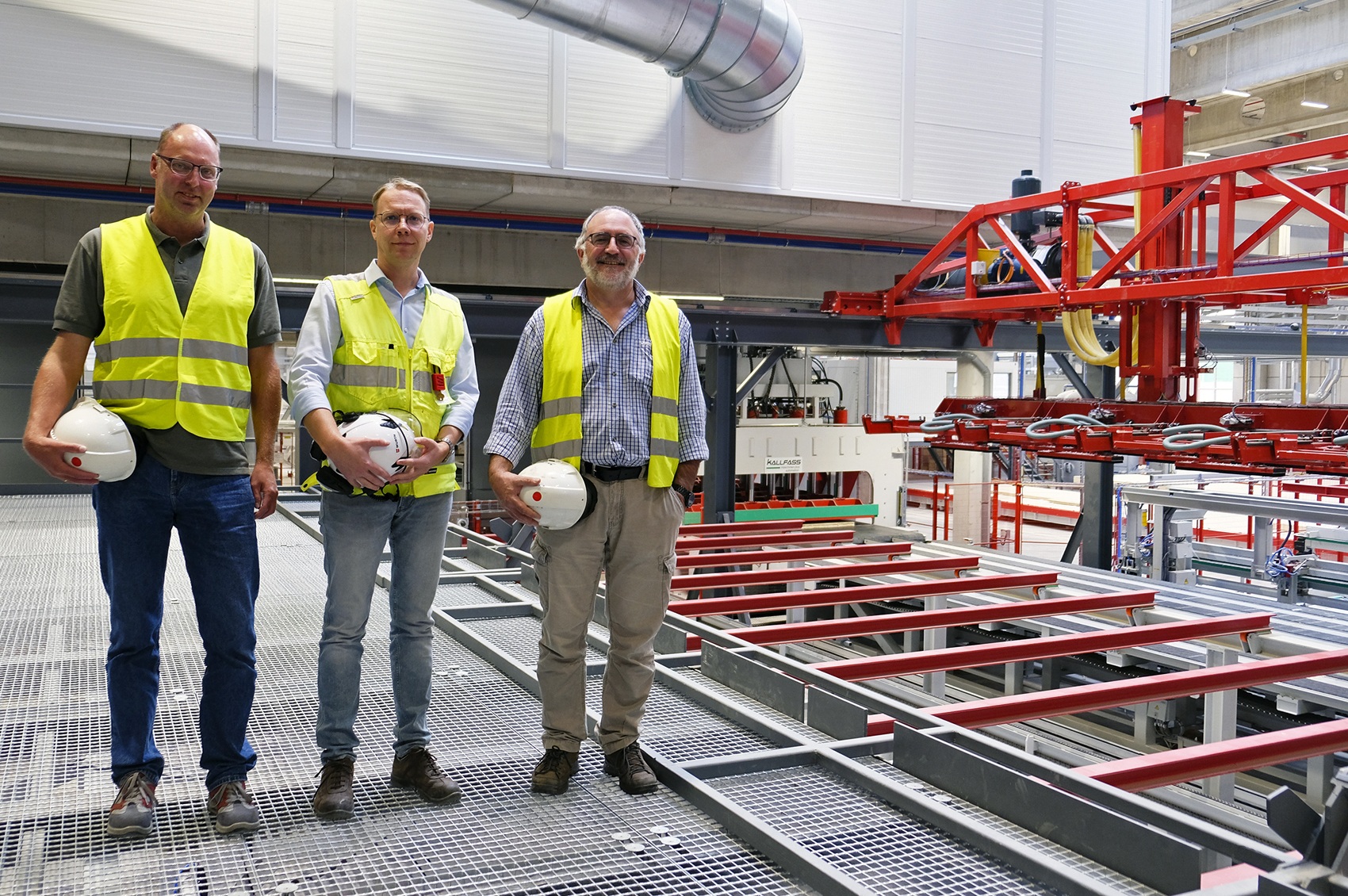

Ransford and Kallfass enjoy a partnership that goes back a long time: the first Kallfass stacking line was purchased 26 years ago. Ten years later, a box sorting system followed, which is still in operation today. “Kallfass is a very reliable partner who delivers the best technology available on the market. And when it comes to customer support, Kallfass is outstanding. The first discussions for the post-pointing system—a fully automatic fence production system—started in 2018. “The sale and planning then coincided exactly with the start of the COVID-19 pandemic. Due to Ransford’s confidence in our technology, we were able to handle the signing process exclusively online via team meetings”, Matthias Link, responsible for sales at Kallfass, explains the challenges.

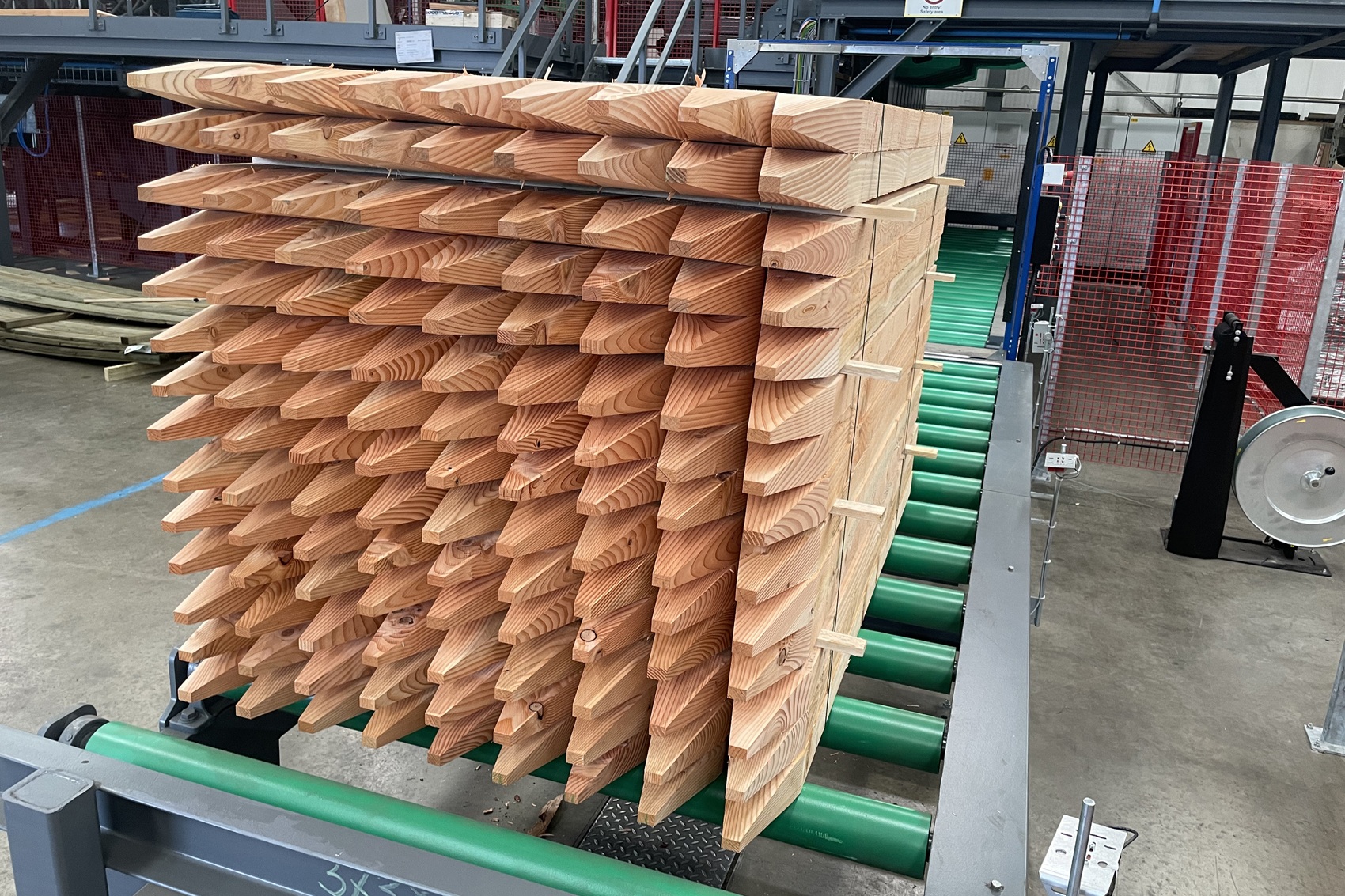

Charles Ransford & Son from Bishops Castle, England, specialises in the manufacture of fence posts, among other things.

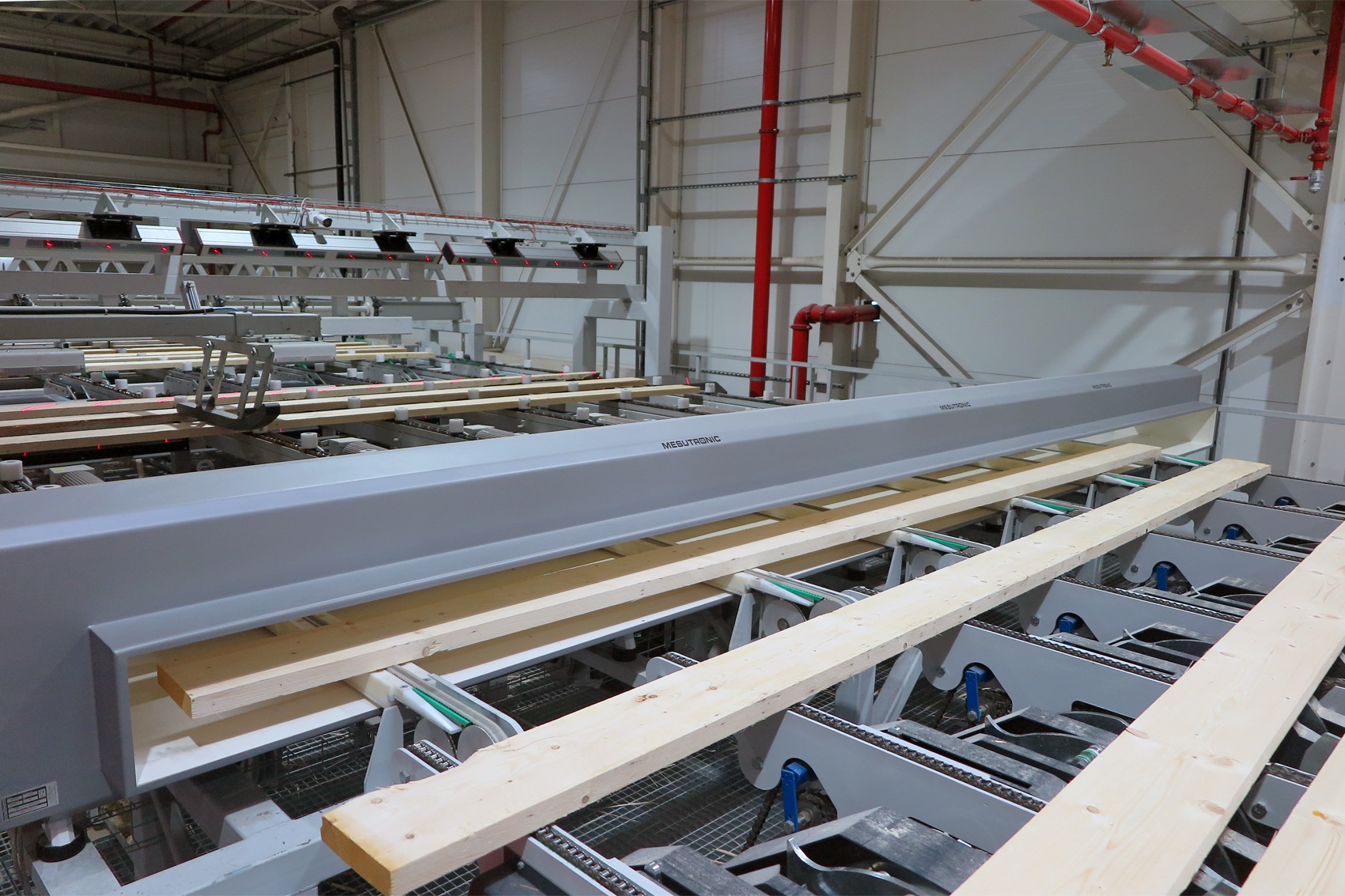

Around 30% of the sawn goods produced are sorted using the layer sorting system —the cross-section at Ransford ranges up to 200 by 200 mm.

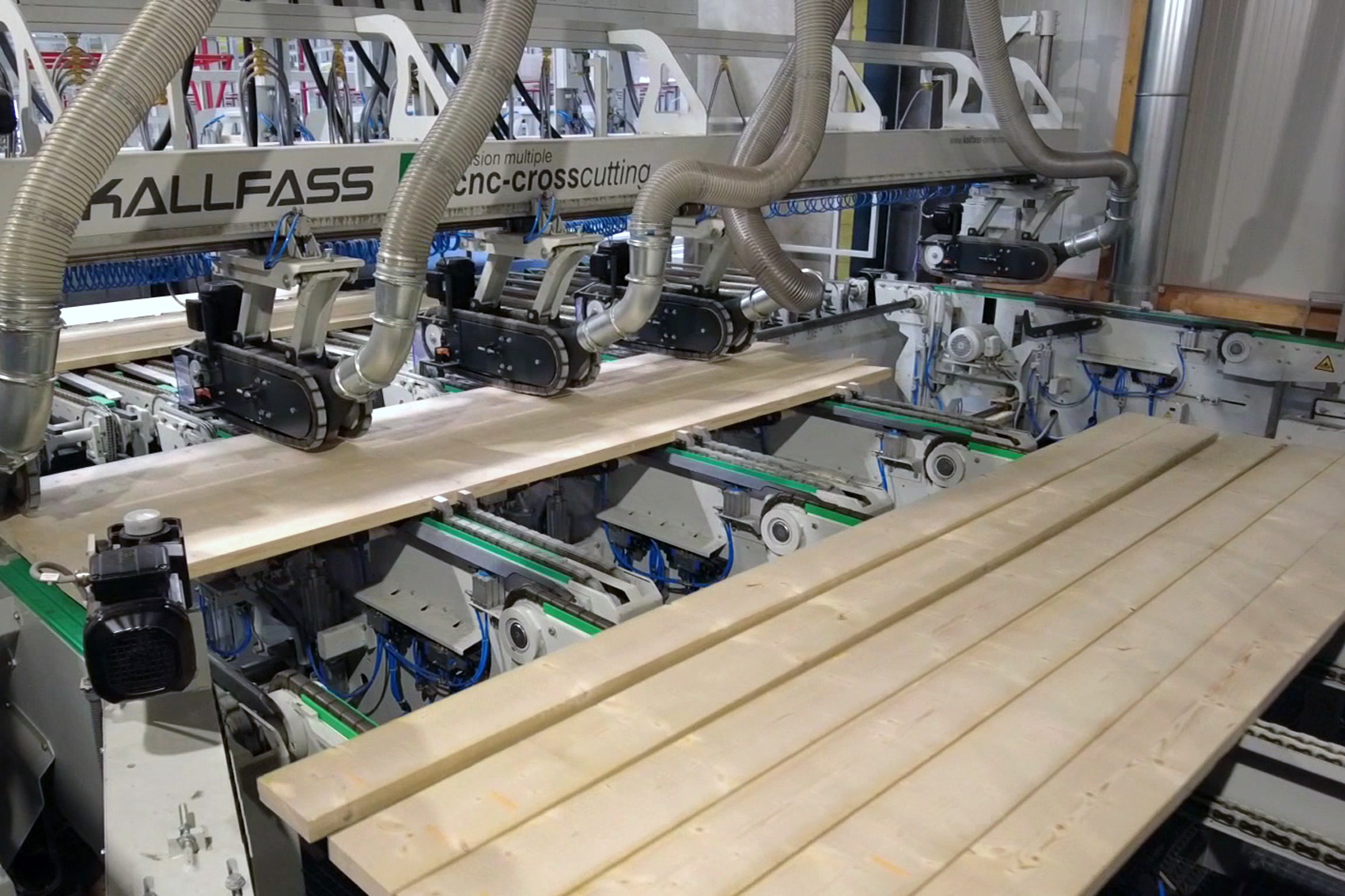

The tried-and-tested multiple cross-cut saw from Kallfass cuts the timber to the required length before it is stacked.

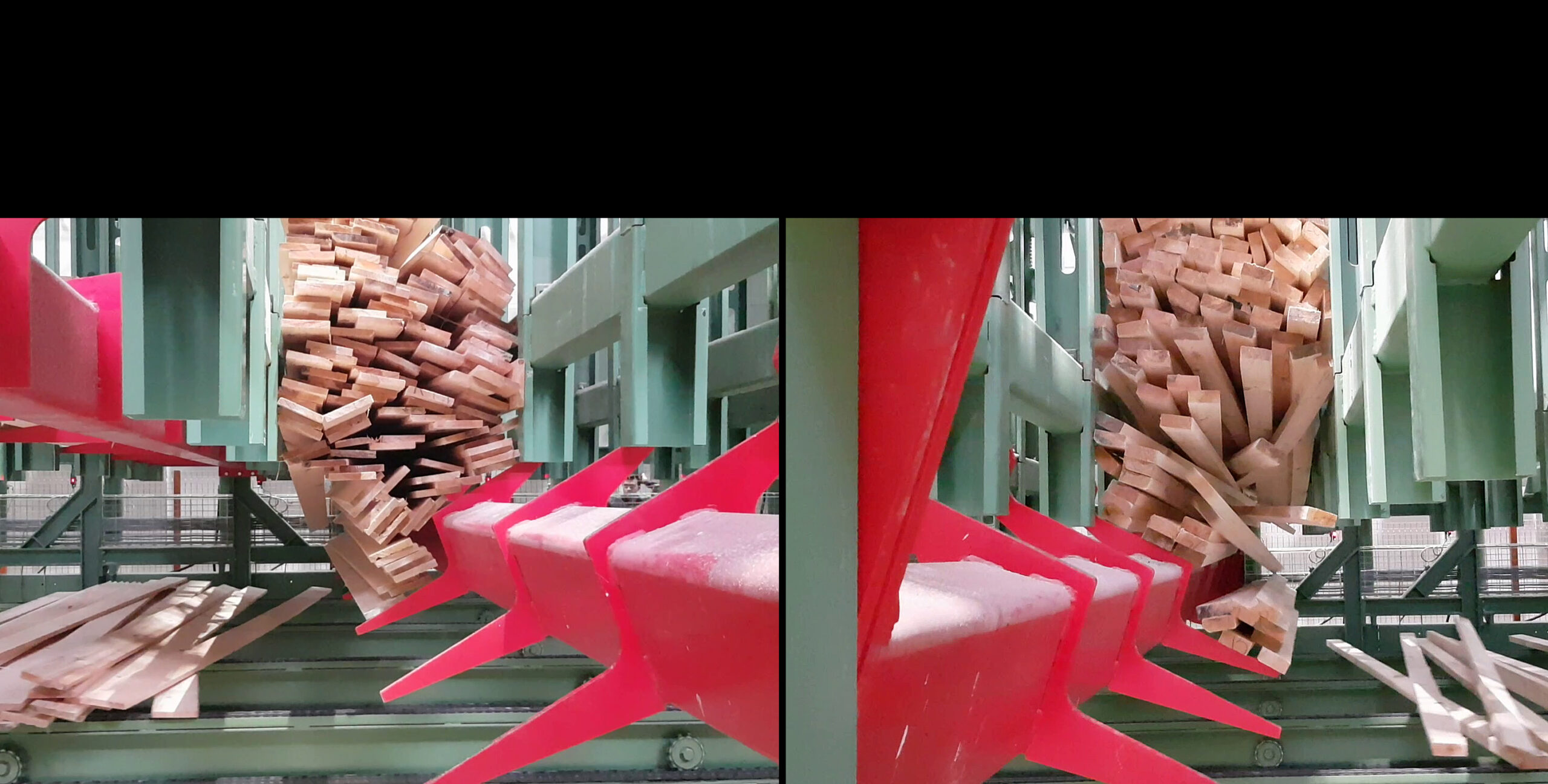

In the Kallfass post-pointing line, four circular saws “point” the posts in a cross-cutting cycle – after each saw, the post is rotated 90°.

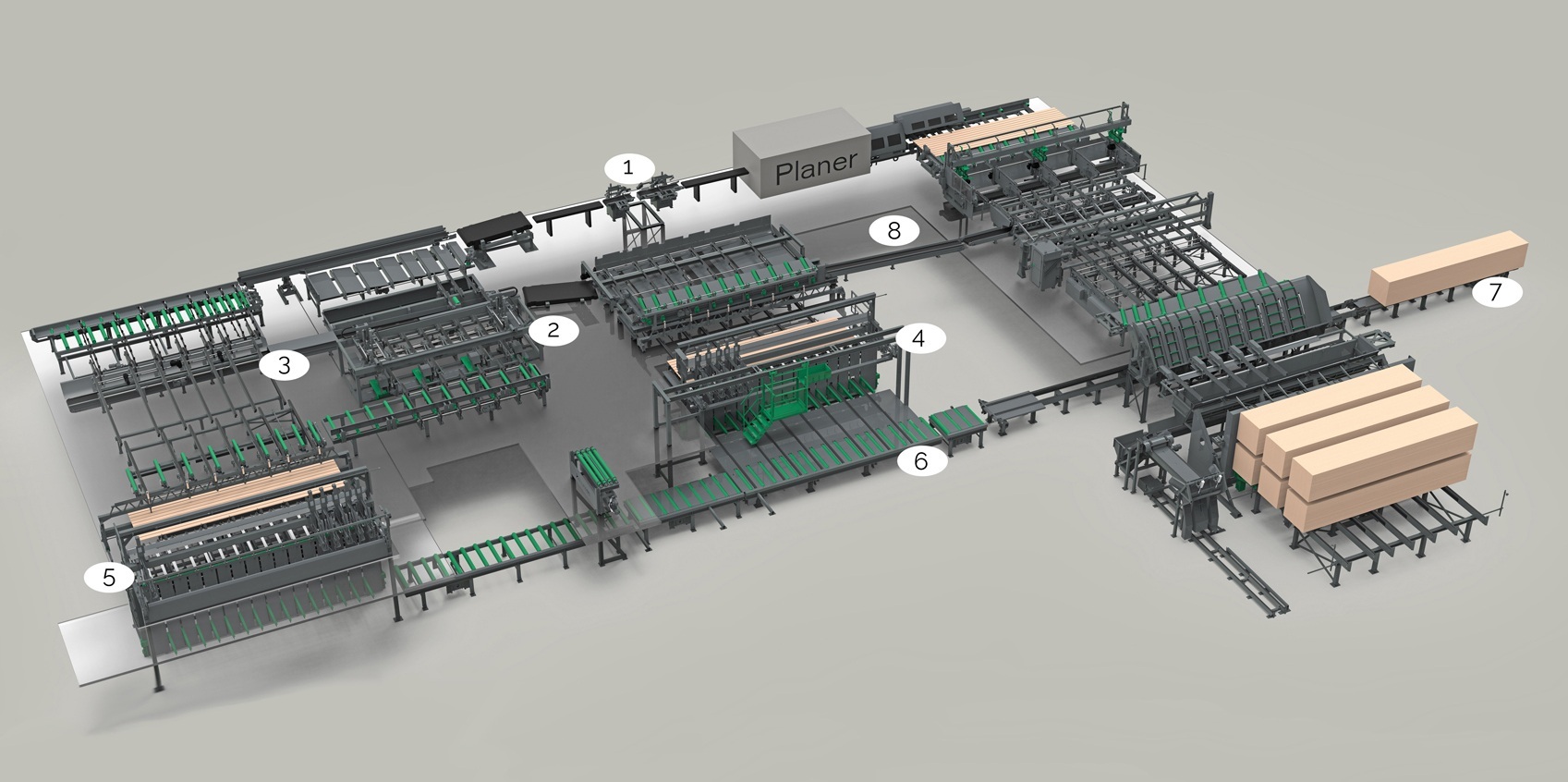

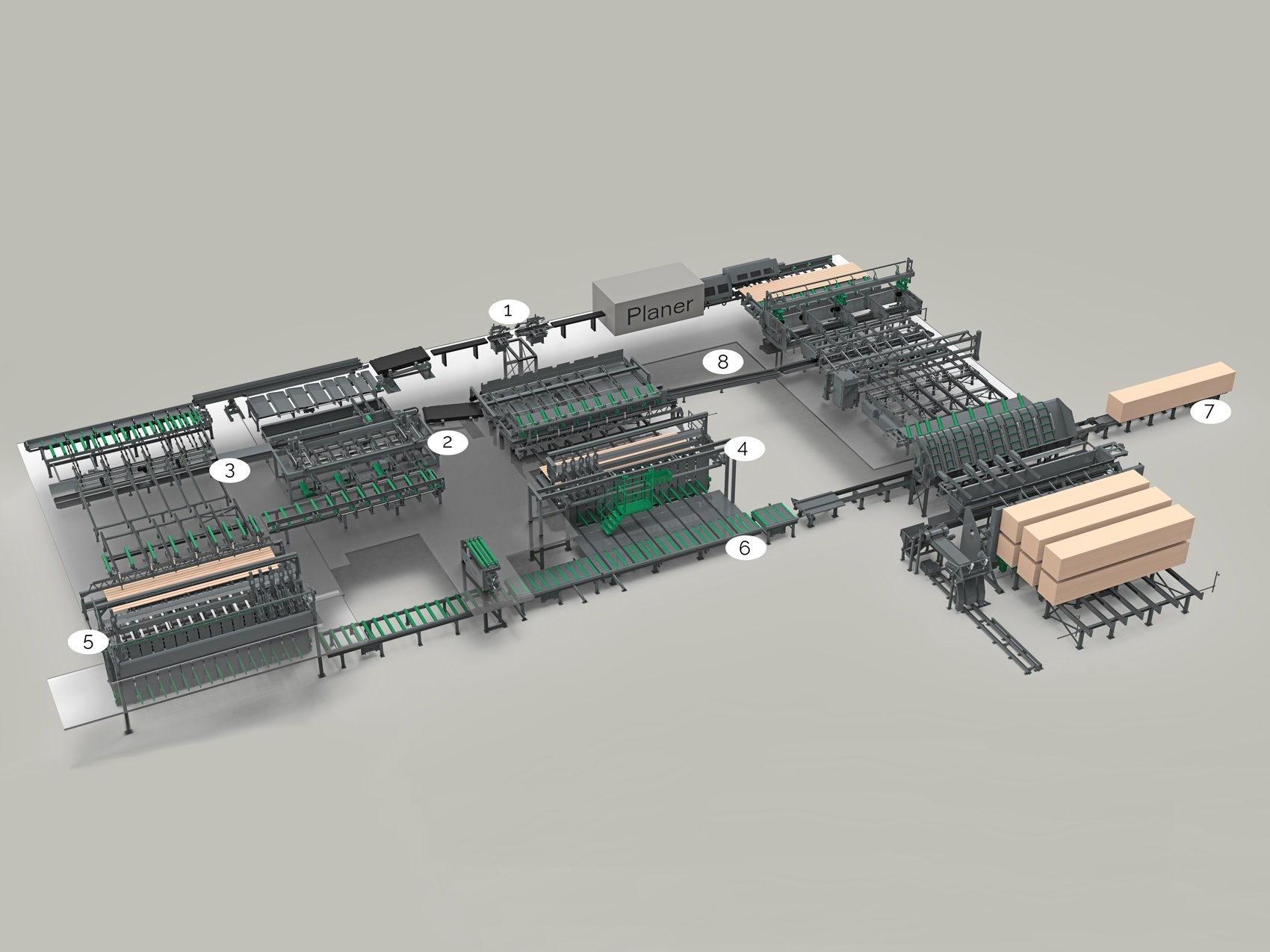

New tray sorter

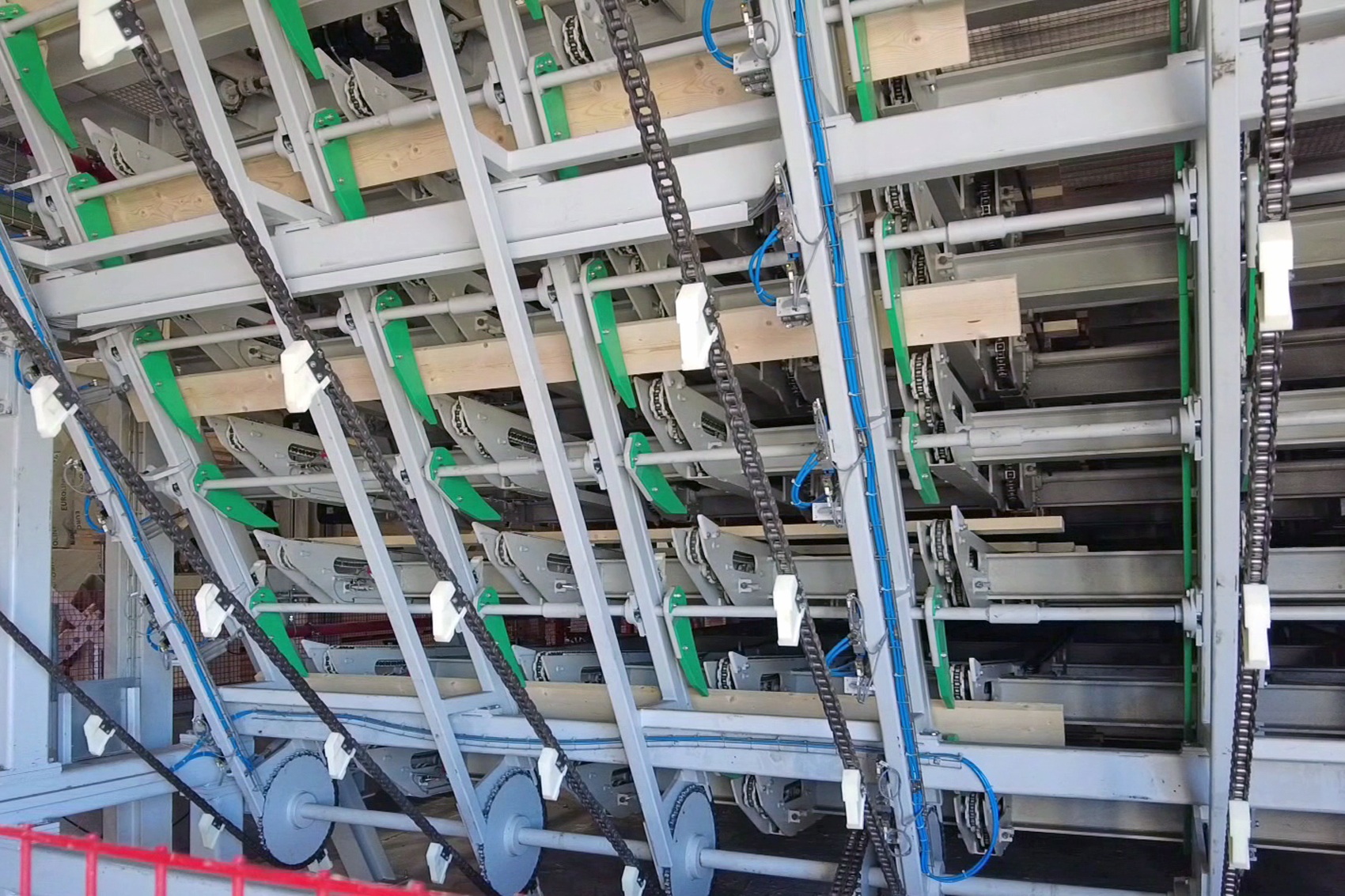

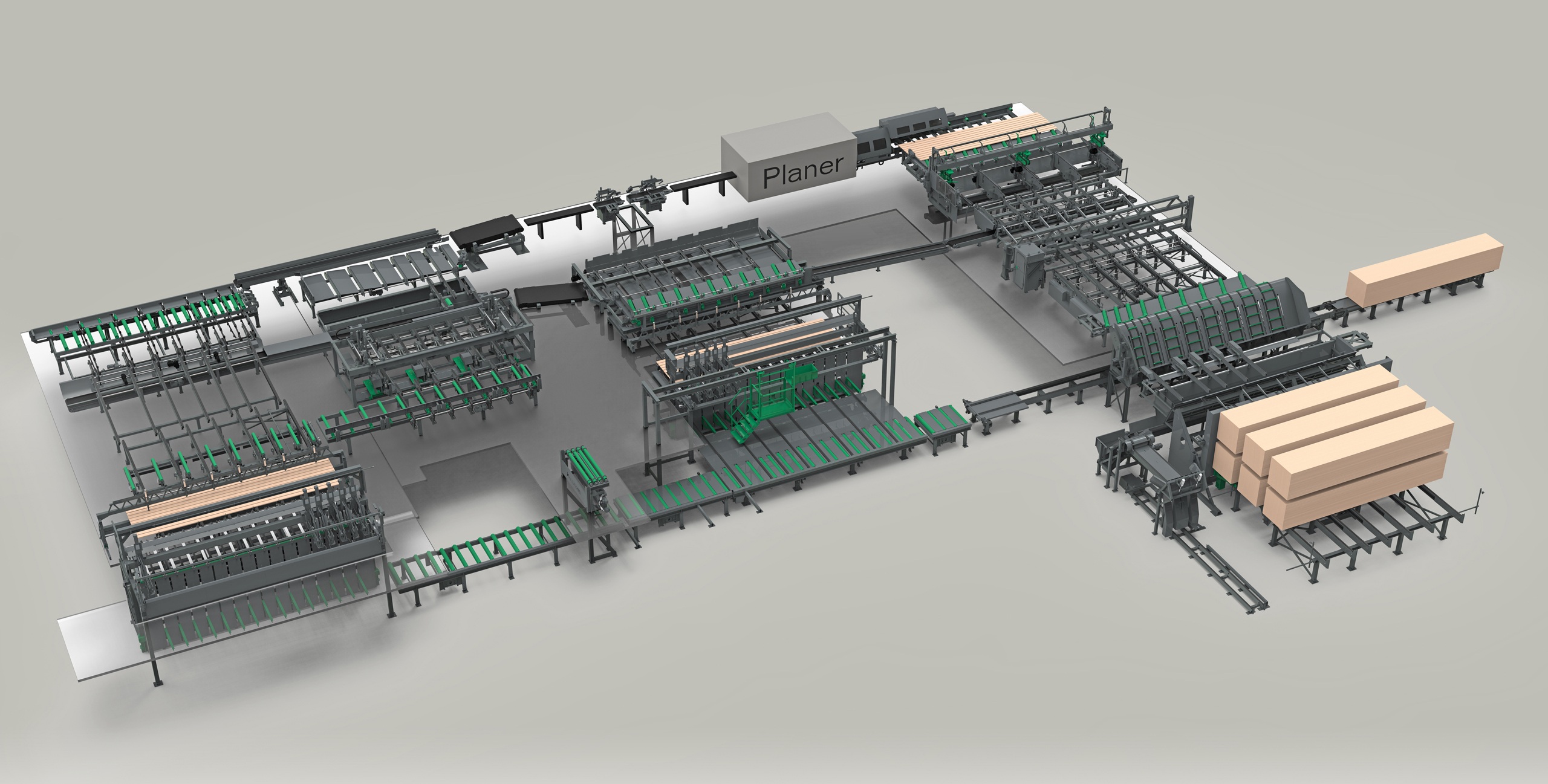

Upstream of the post-pointing plant, is Kallfass’s new sorting system, which has been in operation since October 2022. This system is specially designed for thicker cross-sections, measuring up to 200 by 200 mm and lengths of 1.8 to 4.8 m for gate posts or wooden sleepers. “Until now, we have been implementing the stacking of these systems by hand, requiring an enormous effort. When the new Kallfass tray sorter line is installed, we have taken another important step towards increasing productivity”, says Leitch.

The saw line made by EWD GmbH separates the squared timber and transfers the parts to the Kallfass roller conveyor at a speed of 120 m/min. Workpieces longer than 5 m or unsuitable can be discharged into a green chain. Subsequently, a curved conveyor transports the good parts to the new sorting system. After aligning the timber, an employee assesses the quality of the workpieces and rejects those pieces displaying unsuitable qualities. The measurement is carried out in a crosswise pass. Based on the measurement data, pivoting conveyors are used to place the timber on one of the four levels.

Immediately after emptying of the workpieces, the Kallfass automated system creates the layers. These layers enter the multiple cross-cut saw, equipped with zero-cut and two variable saws. The subsequent stacking uses five magazines where the sticks are placed automatically. Next, the system forms bundles with a cross-section measuring up to 1.2 by 1.2 m. The bundles then leave the hoisting unit, and a roller conveyor transports the bundles to the strapping unit. Here, a stacker picks them up and moves them to the post-pointing unit.

Significantly reduced manual handling

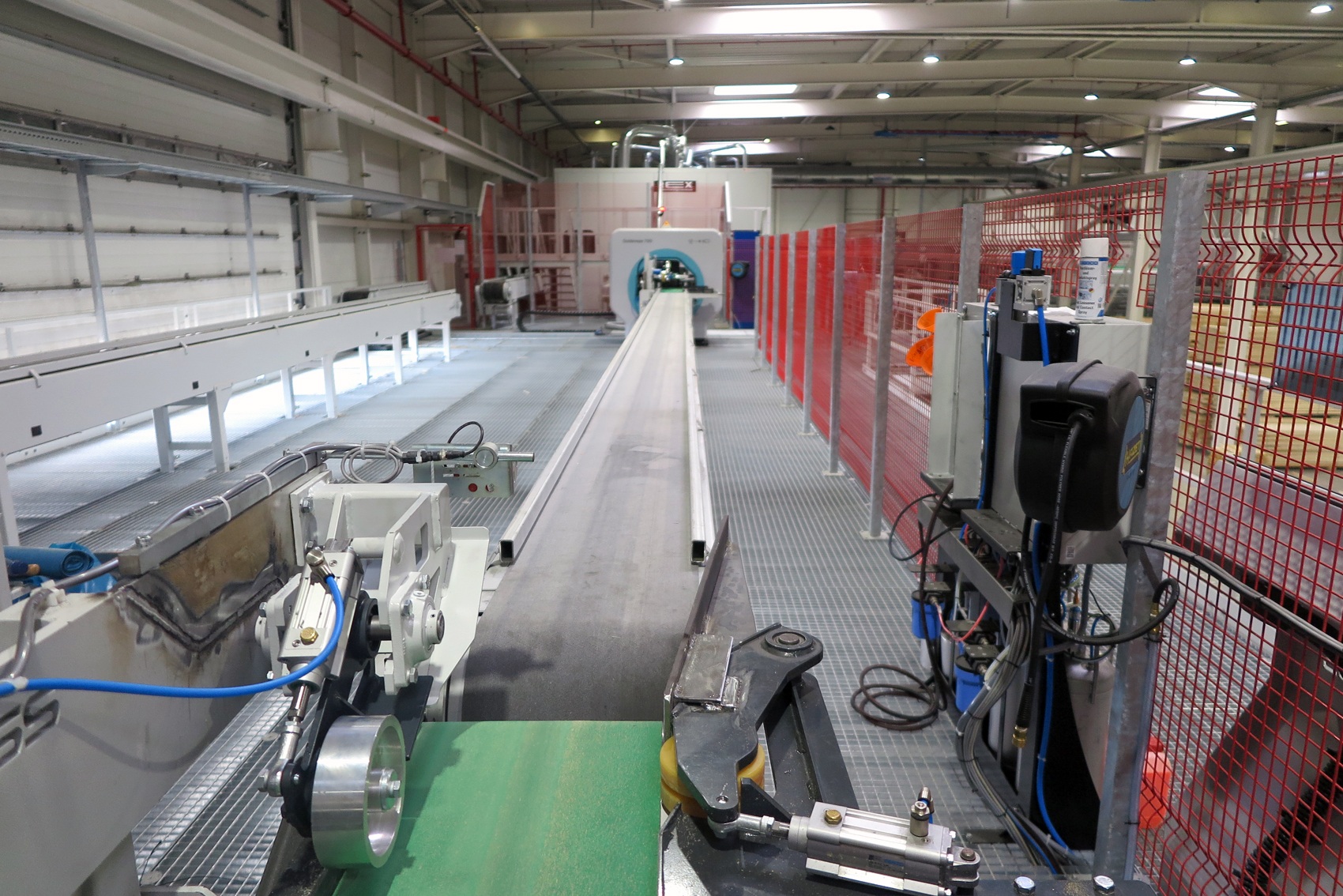

Previously, several employees were required to do the work; now, the post-pointing line takes over this process. “Today, however, only one operator is needed to complete the task“, explains Alex Cooper, the responsible engineer at Ransford. The post-pointing line processes wood cross-sections of up to 200 by 200 mm and post lengths ranging from 1.5 to 3 m.

Inside the new system, the packages are first destacked in layers, and the sticks are automatically stripped. Next, the operator assesses the lumber’s quality and uses a piece of chalk to mark any piece of timber that does not meet the required qualities. The identified parts can be automatically ejected later in the process. In the longitudinal pass, the squared timber enters the incisor (a device for scoring the wood, ensuring better penetration of the impregnating agent). Subsequently, automatic zero-point alignment takes place upstream of the post-pointing station. Finally, in the cross-cutting station, circular saws with a maximum cutting depth of 200 mm point the posts on all four sides while the timber rotates 90° automatically between saws.

Alternatively, the squared timber can also be processed using a radius milling cutting station instead of the circular saws. The squared timber is aligned beforehand and fixed in place using clamps. Two profiling units mill the rounding in synchronous and counter-rotation and thus ensure uniform processing without fraying of the posts. “The milling station has a capacity of up to six pieces per minute”, Link explains. The downstream Kallfass stacking system stacks sawn posts in single or multiple lengths, and places the sticks automatically. According to Link, the system has an output of up to five layers per minute. For Ransford, the clean packages, in particular, are also a definite benefit compared to the past: “The beautiful appearance of the uniform stacks makes a much better impression on the customer”, confirms Leitch.

Last year, Kallfass delivered two systems to Charles Ransford & Son: at the end of October 2022, the sorting system with four levels went into operation; before that, the system specialist had already installed a post-pointing system.

In addition, Kallfass installed a milling station in the fence production system when a profiling unit was installed for circular milling of the squared timber.