Alternatives to scanning: Manual quality assessment of timber with the KALLFASS assessment chain conveyor.

Holzkurier 13/2021

Holzkurier 13/2021

Kickoff in Wunsiedel was December 2019, with the first trunk being fed through the new line exactly one year later. Construction of the GELO Timber sawmill continued during the most difficult times imaginable. Despite all the adversities the Corona pandemic presented, it proved possible to adhere to an already tight schedule.

The main product, predominantly lamellas for glulam timer, is intended for the supply of glulam plants. Side boards which cannot be processed are supplied to packaging customers. “In future, the sawmill will reduce purchasing considerably for both companies in Wunsiedel and Weißenstadt. However, 100 % self-sufficiency is not possible”, explains Küspert. Wunsiedel primarily proved attractive as a location because GELO Timber had in WUN Bioenergie a pellet producer and cogeneration plant operator as a neighbour. But WUN Bioenergie is not just any neighbour: Küspert is co-initiator of the energy park and, additionally, a shareholder and Managing Director. This creates attractive synergies with, in essence, sawmill waste being exchanged for electricity and heat. Küspert calls the sawmill the “Smart solution 4.0”.

An enormous feat

Construction commenced in Wunsiedel in December 2019. An already tight schedule was adhered to, despite the Corona pandemic, and the first trunk was fed through the saw line a year later in December 2020. “It was an enormous challenge for everyone involved, but we were able to commission the plant within the given time”, says the Managing Director, and he is proud of how successful this cooperation has been. A second shift was already launched a few weeks ago. The sawmill has been designed for an annual output of 350,000 solid cubic metres in two shifts. “That may not seem a lot at first glance, but more than 18 million linear metres of logs need to pass through the plant every year to achieve this output. Our sawmill in Weißenstadt, where we process larger diameters, is only handling 4 million linear metres for an output of 250,000 m³/per annum”, relates Küspert. The Wunsiedel sawmill is intended for thin-end diameters of 8 to 25 cm and a timber length of 2.5 to 5.3 m.

Clean sorting

Main and side boards are conveyed via a tilt destacker onto two separate decks towards the sorting and stacking system from Kallfass in Klosterreichenbach/DE. The mechanisation specialist also installed an automated stick feeder. The main and side boards are fed through an unscrambler onto a curved conveyor. The worker assesses the timbers on the downstream conveyor. If a face section is necessary, he pulls the board up to 0.5 m from the conveyor. During the visit, Kallfass Project Manager Matthias Link pointed out the rollers that make handling of even heavy boards extremely easy.

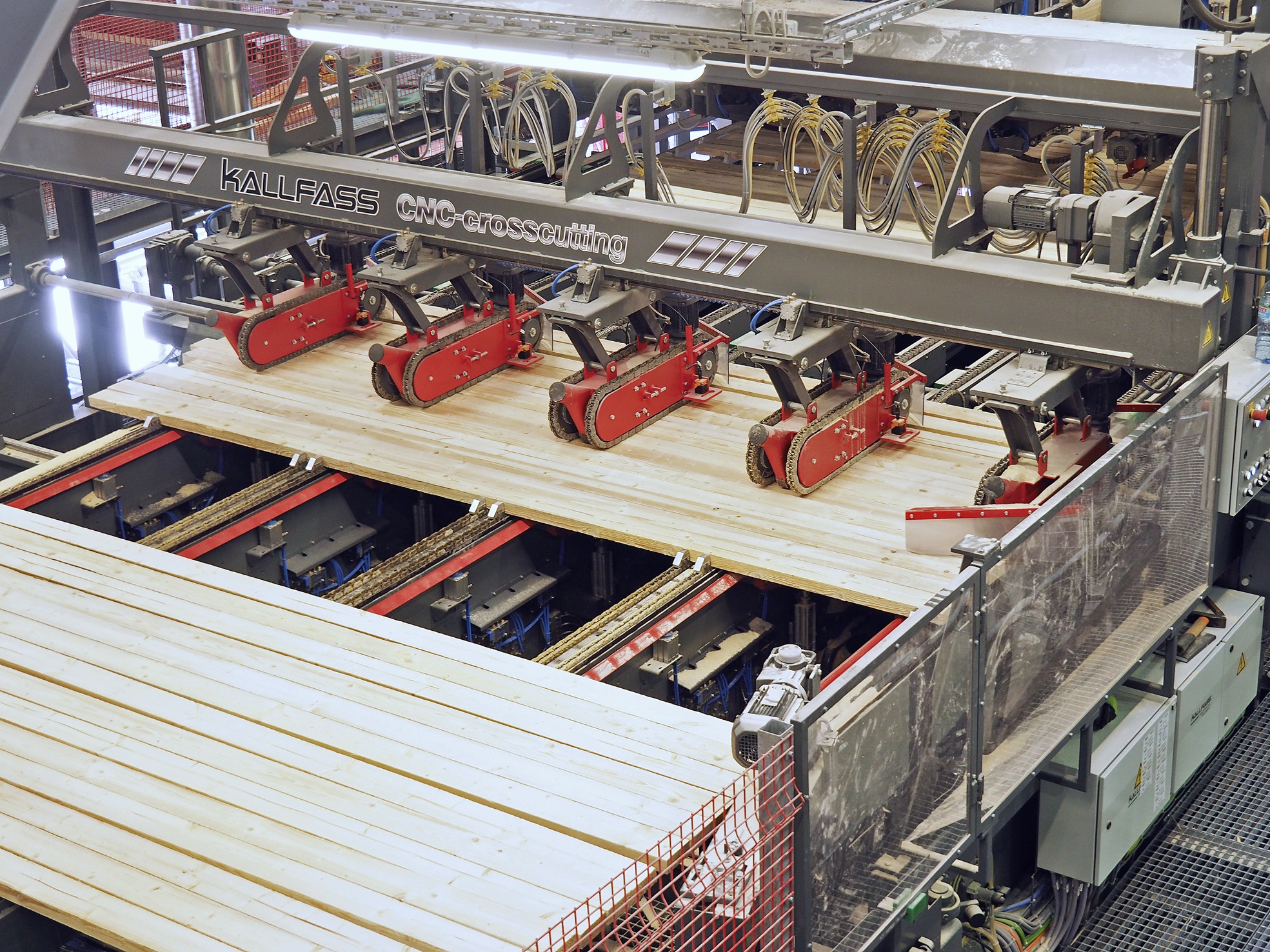

Single feeding with a TongLoader towards the wane scanner and trimmer occurs in the transverse run-through. The TongLoader grips each piece in a manner similar to a hand, separates the board film, singulating and feeding it into the next conveyor. The significant advantage of the TongLoader is that it can also handle different timber dimensions, piece by piece. Link indicates that the Kallfass sorting system output is up to 120 cycles per minute.

A Microtec scanner determines the dimension and detects the wane. The Variosort sorting control system assigns each board an appropriate box number and information for the downstream Kallfass trimmer. The latter has seven saw blades and can also be used for destructive cuts. “The operator can also indicate additional characteristics for boards through colour marking, indicating conditions such as beetle damage, blue stain or rot”, explains Link.

Wolf-Christian Küspert, Managing Director GELO Timber

Boxes up to 30 % larger

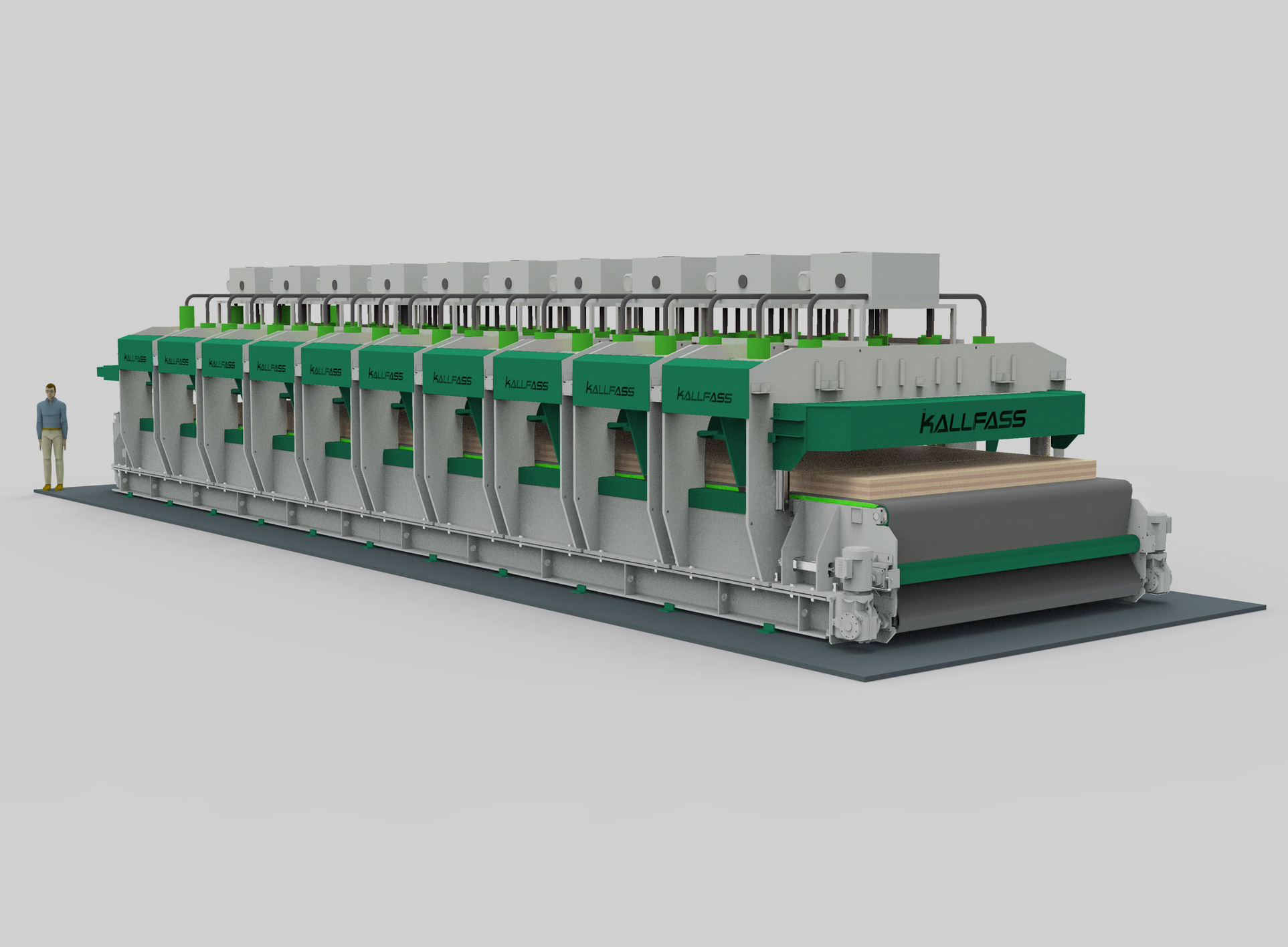

GELO Timber decided to pick 40 inclined boxes. In order to reduce stacking on the premises, the Kallfass system can stack packages with a width of up to 1.65 m and a height of 2 m. These dimensions also facilitate best possible exploitation of the Valutec continuous kiln. Kallfass created larger inclined boxes than usual for this reason. “The boxes are around 30 % larger”, says the Kallfass Project Manager.

Full boxes are emptied downwards onto a cross conveyor and separated by a step separator. Kallfass also installed the re-sorting system for kiln packages above the cross conveyor, with one kiln package making up to two or three shipping packages. These are separated in layers through tilt destacking. The stacking sticks fall automatically onto a conveyor belt and are collected separately.

A worker can even assess the quality of both damp and kiln timber again if necessary, or reject undesired pieces. Subsequent to this, the Kallfass mechanisation system creates the layers according to the package specification, and these are conveyed through the Kallfass multiple cross-cut saw. This is equipped with a zero line and four variable saw aggregates. Placement forks then transfer the completed layers to the stacking system. Stacking output is up to twelve layers per minute.

The Kallfass stacking system is equipped with eight double magazines for kiln and dispatch sticks. Kiln sticks are 1.6 m long, while dispatch sticks have a length of 1.2 m. Strip laying is automatic. Finished packages are lowered using a paternoster lift. Damp material is conveyed from there to the Valutec continuous kiln opposite. Shipping packages are conveyed to a Fromm strapping station which Kallfass has retrofitted with an automated feeding system for squared timbers.

As initially mentioned, Kallfass also provided the automated stick feeder for kiln and dispatch sticks. The feeder was automated to cope with the volume of kiln sticks required. Stick bundles are transferred to a cross conveyor and separated. A scanner checks the dimensions and detects damage to sticks such as knotholes and splitting. Unsuitable sticks can be ejected downwards through a flap. Following scanning, the sticks are collected and bundled with ten sticks per bundle. Dispatch sticks are provided using a manually charged belt conveyor. A robot grips the stick packages, filling the stacker magazines with them. The major advantage of this solution is the option to position the magazines variably and still fill them automatically.

Successful project

Complete administration of the sawmill is handled by GELO in Weißenstadt. This enabled them to keep personnel figures low in Wunsiedel. “We currently have 32 personnel working in two shifts. The sawmill can be operated by a mere eleven people during each shift. We wanted to build an absolute jewel – and we’ve succeeded in this in every respect. All the solutions involved were implemented exactly as we imagined. The new sawmill means we are well equipped to face the future”, says Küspert. He is particularly proud of the overall concept involving the neighbouring pellet and cogeneration plant – “It’s a location advantage that nobody can take away from you”.

The complete investment involved EUR 38.5 million. The sawmill location covers an area of 11 ha, 7 of which are presently in use. Küspert also has a few pleasant ideas regarding the rest of the location. “But first, our main focus will be on the new sawmill”, concluded the Managing Director.

Handling of stacking sticks often appears to be something of a “side issue”. However, the Kallfass installation at the Sägewerk Egger sawmill in Brilon demonstrates the enormous workload reduction automatic feeding brings in packet assembly.

Several thousand stacking sticks need to be handled daily at the Sägewerk Egger sawmill in Brilon. “Previously, the continuous filling of stacking plant magazines during main and side board sorting was an enormously laborious task”, relates Jens-Michael von Werder who is responsible for production technology at the sawmill. Up to nine workers were involved in each shift, which meant a considerable number of personnel were working during three-shift operation. For this reason, it was decided to invest in an automated stick handling system with robot charging of magazines at Egger.

Flexible solution

“We found the standard variants available too rigid. We wanted a flexible solution which we could use to handle both drying chamber and stabilisation battens and squared timbers”, continues von Werder. Kallfass, Baiersbronn/DE, offered Egger the perfect solution. “We’d already gain a positive impression of Kallfass during a project in the planing mill. Aside from this, Kallfass has always proved to be a good partner when it came to tackling challenging tasks”, says von Werder. The mechanisation specialist presented those responsible at Egger with a flexible solution that appeared to offer them cutting-edge technology. “We had already installed other automated stick systems in the past, but the project at Egger in Brilon was the most comprehensive to date”, explains Kallfass Managing Director Hans Haist.

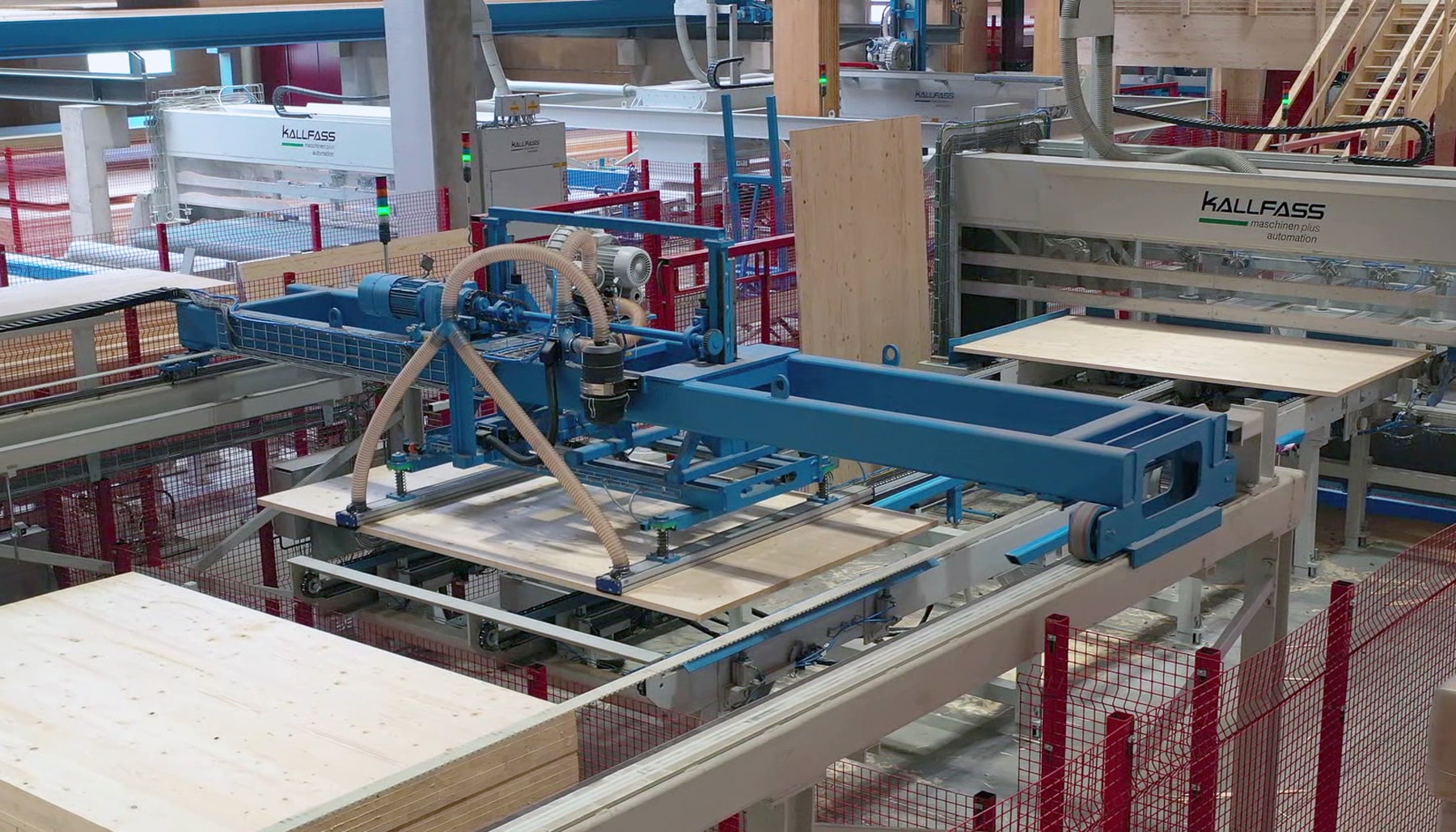

Two lines, three robots

The “open-heart surgery”, as von Werder describes it, was performed from April to September, with Kallfass realising the entire automated stick line installation while plant operation continued. The actual installation took two months. “The project went very well and, most importantly, free of accidents. We had practically no downtimes”, confirms von Werder. Egger in Brilon cuts around 1 million m² per annum. The timber is sorted in main and side board plants which are installed in parallel. The new Kallfass line charges both plants with drying chamber and stabilisation battens and squared timbers. Stacking sticks from the dry sorting station are fed together with the squared timbers in uprights to the new Kallfass line. The uprights are discharged onto a buffer conveyor. The system automatically separates the squared timbers from the sticks. The squared timbers are then fed to a stacking system via a separate chain buffer line. The Kallfass control system assigns the squared timbers to both stacking plants based on package data. The sticks take another route, with the Kallfass mechanism separating these and feeding them through a scanner. This determines the dimensions and curvature. Unsuitable sticks are discharged through a flap. The system handles eleven sticks together in each case on an inclined conveyor.

Jens-Michael von Werder, responsible for production technology

Andrea, Hubertus and Paul

Andrea, the first robot on the line, grabs these eleven stacking sticks and cycles them into the buffer conveyor. “This is designed for around 3000 sticks”, explains Haist. Hubertus and Paul, the two other robots with swivel arms, pick up the stacking sticks if necessary and deposit them in the new Kallfass packet assembly magazines. “The system is designed for an output of 100 sticks per minute”, estimates Haist. “We hold the property rights to this robot charger”, he adds. There is only one stick length for all package widths in the case of stabilisation battens. These are adapted to the package through positioning and shifting of stick placement. “This solution means we are considerably more flexible than with different lengths, but the cost of materials is higher”, says von Werder. Kallfass also upgraded the stacker and delivered the entire control system over the course of this investment. This means that it is now possible to control the placement of more sticks in the lower five to six layers to prevent timber breakage. From Egger’s point of view, operation of the new stick handling system has been both smooth and absolutely satisfactory. “The goal in the area of stick handling is to now manage with four employees per shift. This means the investment will pay off within a very short space of time”, concludes von Werder.

Photos and text: Martina Nöstler, Holzkurier 51-52/2020

Text Martina Nöstler, Pictures Kallfass, Holzkurier BSP-Special 2020

Holzkurier 34/2020

Training period 3.5 years

What you offer:

What we offer:

Location Klosterreichenbach

Kallfass GmbH

Maschinen plus Automation

Röter Straße 44

D-72270 Baiersbronn

Contact: Volker Kallfass

Phone: +49(0)7442-84460

E-Mail: karriere@kallfass-online.com