Tailored solution for an exceptional sawmill

With log lengths of 1.1 m and over, the Lithuanian Juodeliai Group recently commissioned a high-performance sawmill for producing raw material for pallets. Machine suppliers were also faced with major challenges, given the short logs involved and a planned output of 250,000 m³ of sawn timber per annum. Extensive experience and the level of commitment on the part of suppliers such as Kallfass ensured the success of the project.

The latest and, simultaneously, largest sawmill in the Juodeliai Group is currently operating in Marijampole/LT. The largest sawmill group in the country encompasses four locations and is responsible for cutting over 1.3 million solid cubic metres of logs per annum. Juodeliai aims to produce around 650,000 m³ of pallet timber in 2022, generating over € 200 million in turnover as a result. With customers in over 40 countries, the company is highly export oriented, although, according to CEO Andrius Zimnickas, no business relations are cultivated with Russia or Belarus, despite their geographic proximity. The company mainly obtains its spruce and pine logs and, also, hardwoods from Lithuania, a fact that also makes Juodeliai the largest consumer of timber in the country.

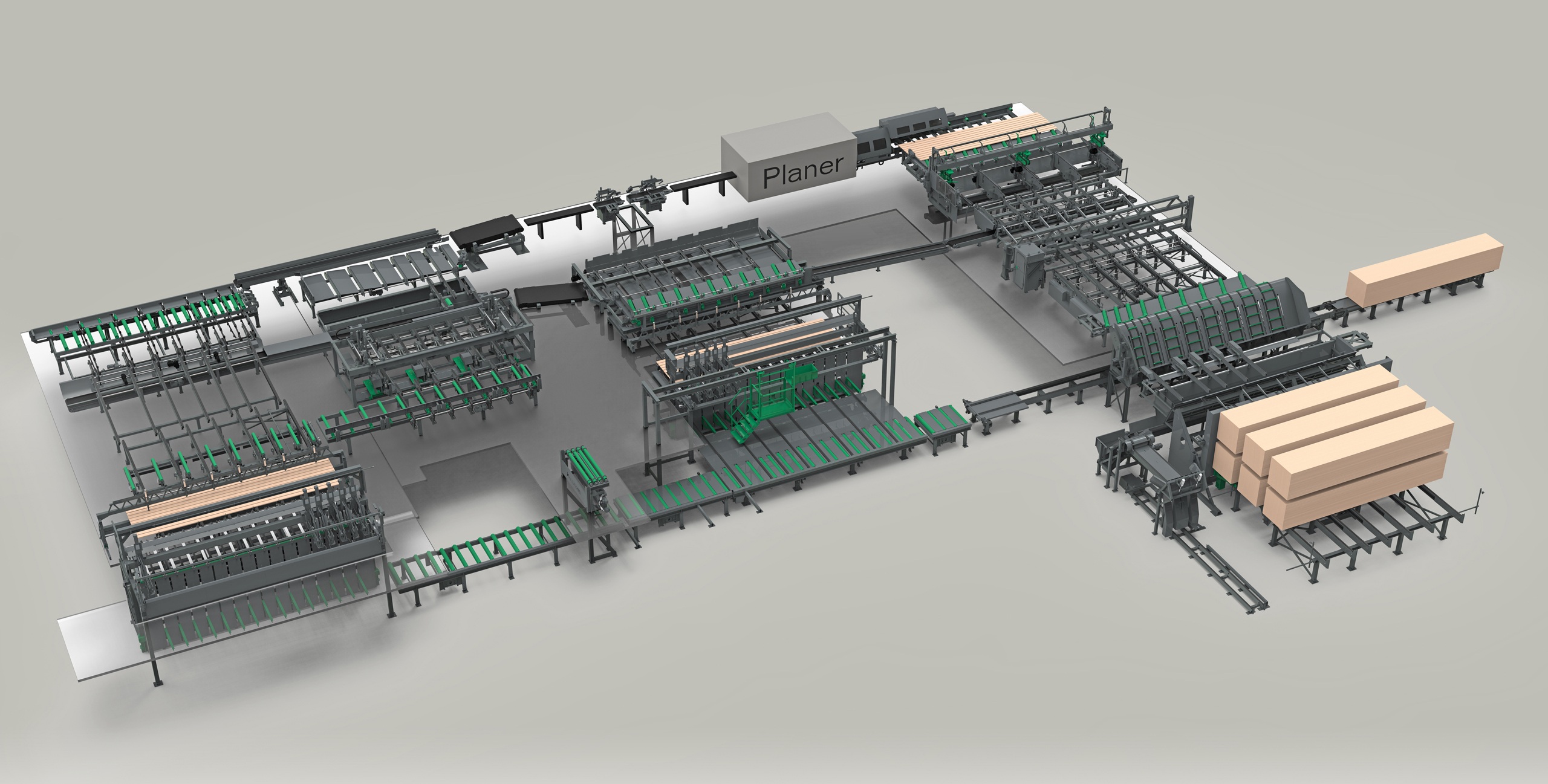

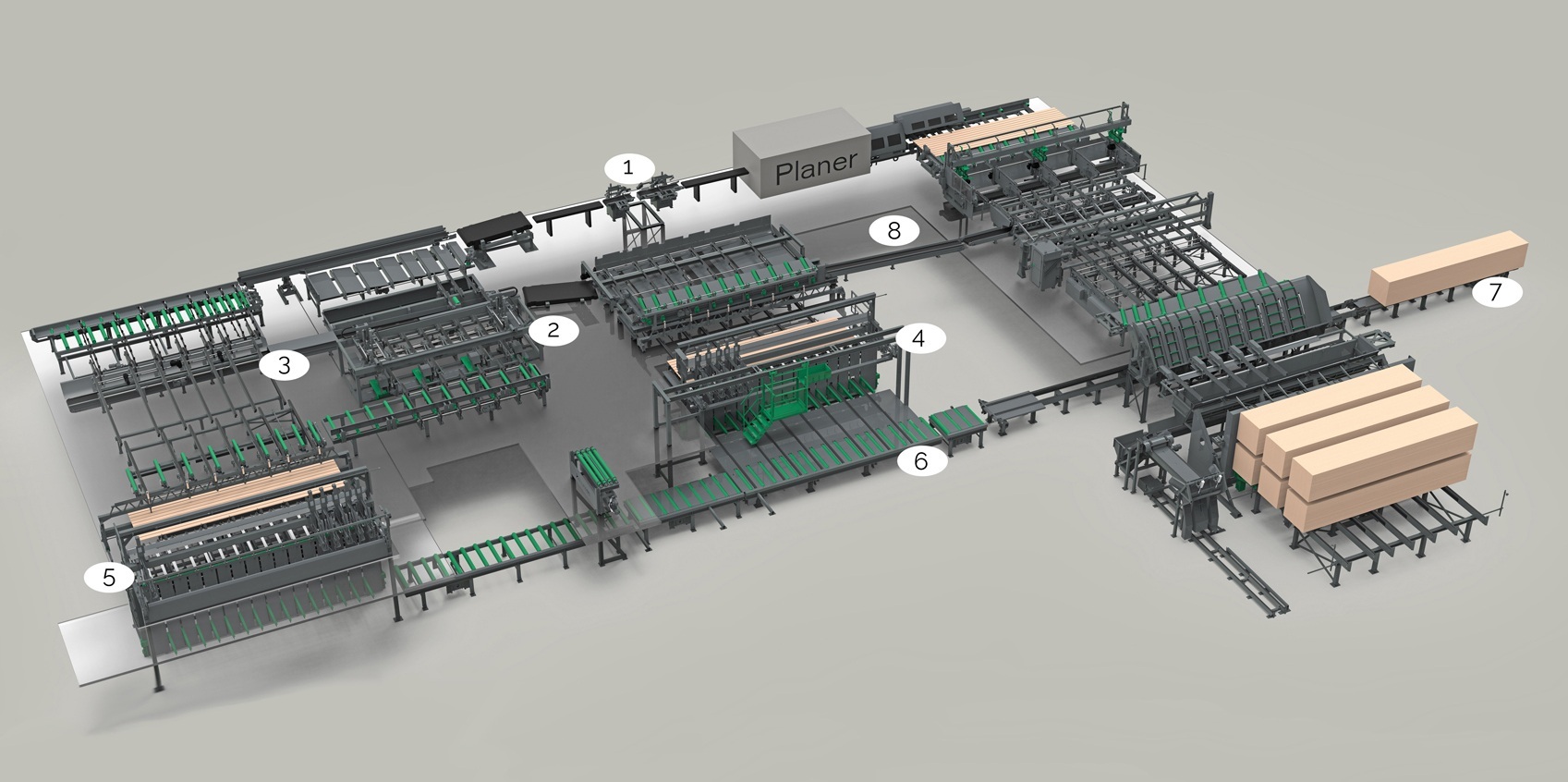

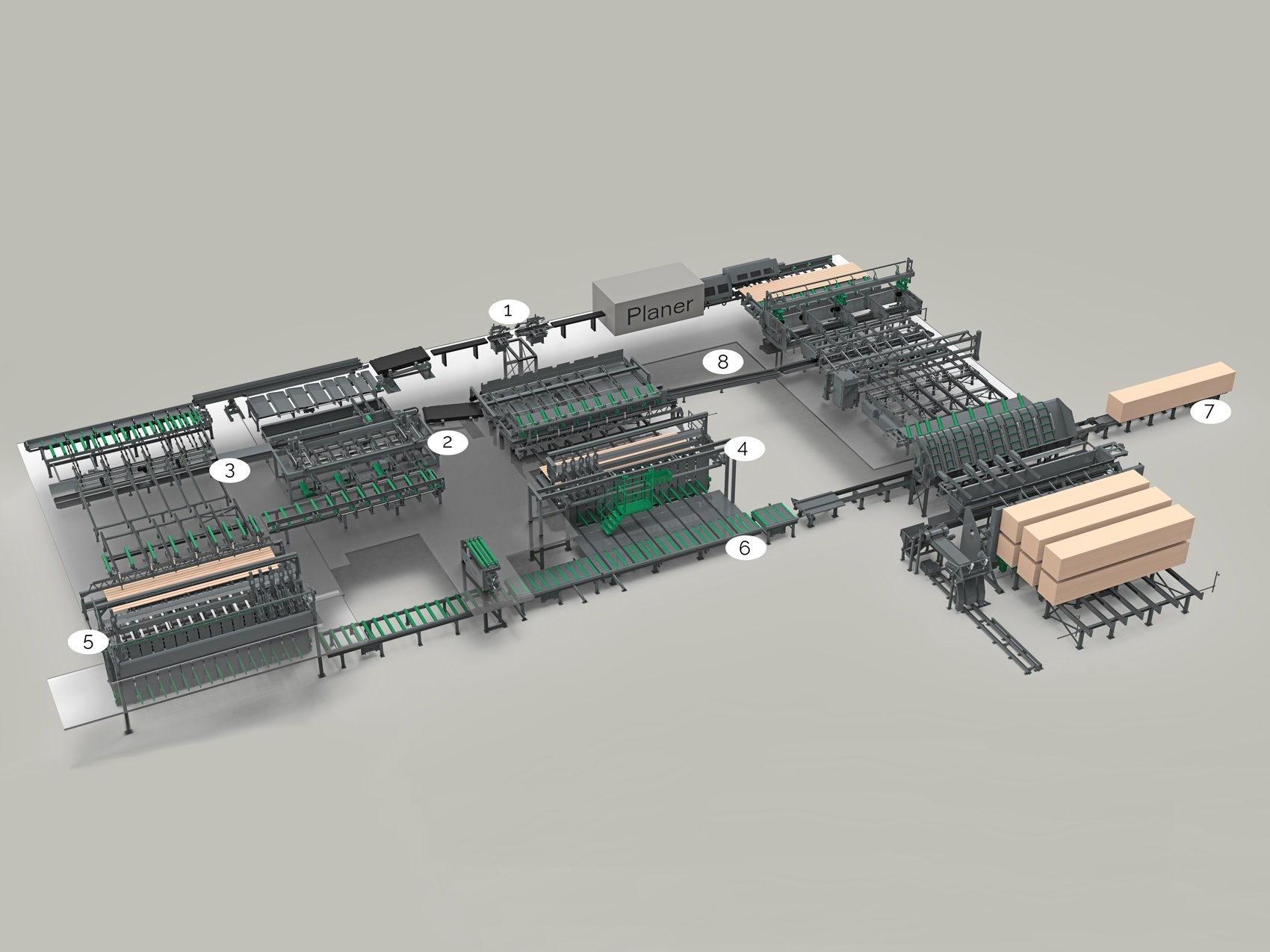

The company commissioned a fourth sawmill in 2020 in Marijampole, about a two-hour drive west of the capital Vilnius. Designed for an annual capacity of 250,000 m³, Juodeliai also produces pallet timber there for the global market. When it came to machine suppliers, the company opted for proven plant solutions from companies such as Linck, Holtec, Microtec and Kallfass. The latter is responsible for the mechanisation, sorting and stacking of main products and side boards.

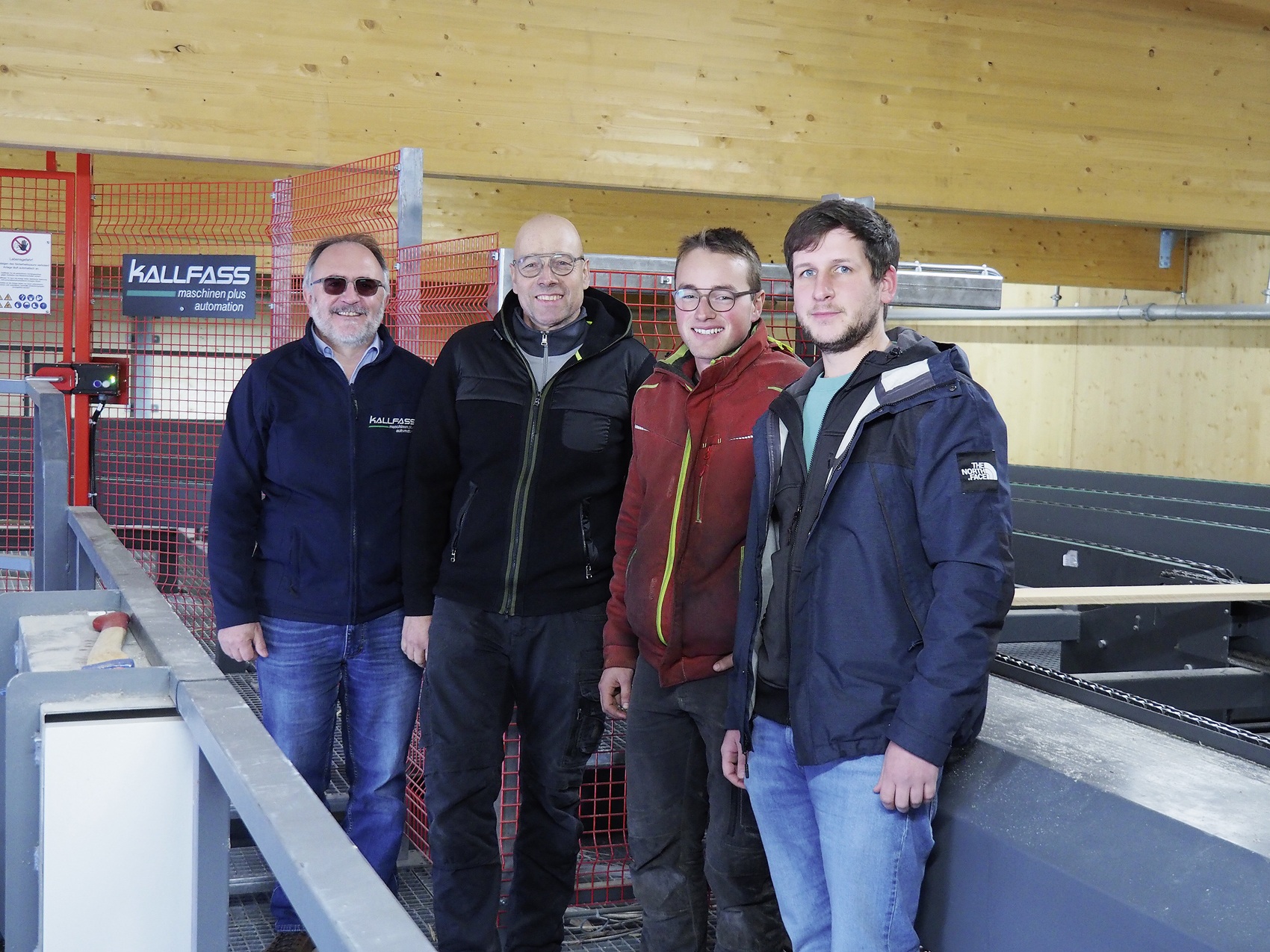

„A practical, solution-oriented approach is the main reason we are cooperating again with Kallfass.“

Andrius Zimnickas, Juodeliai Group CEO

A challenging project

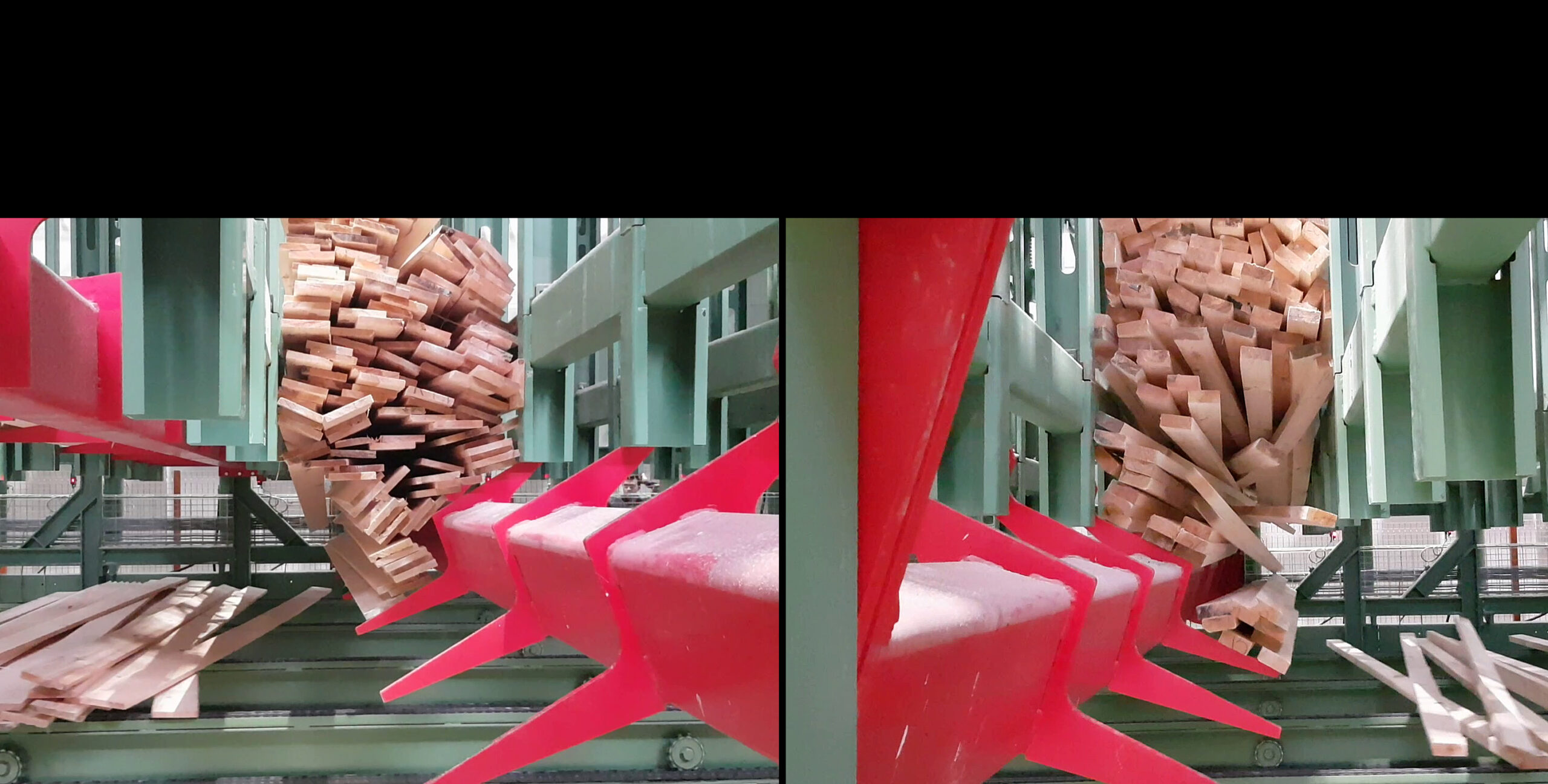

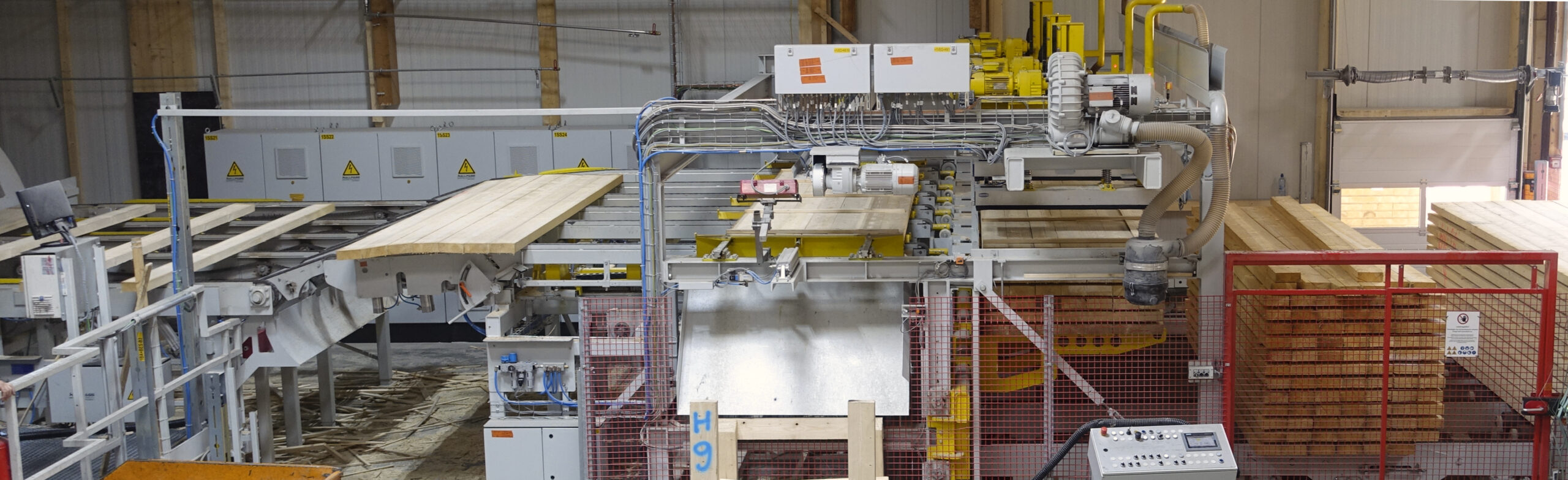

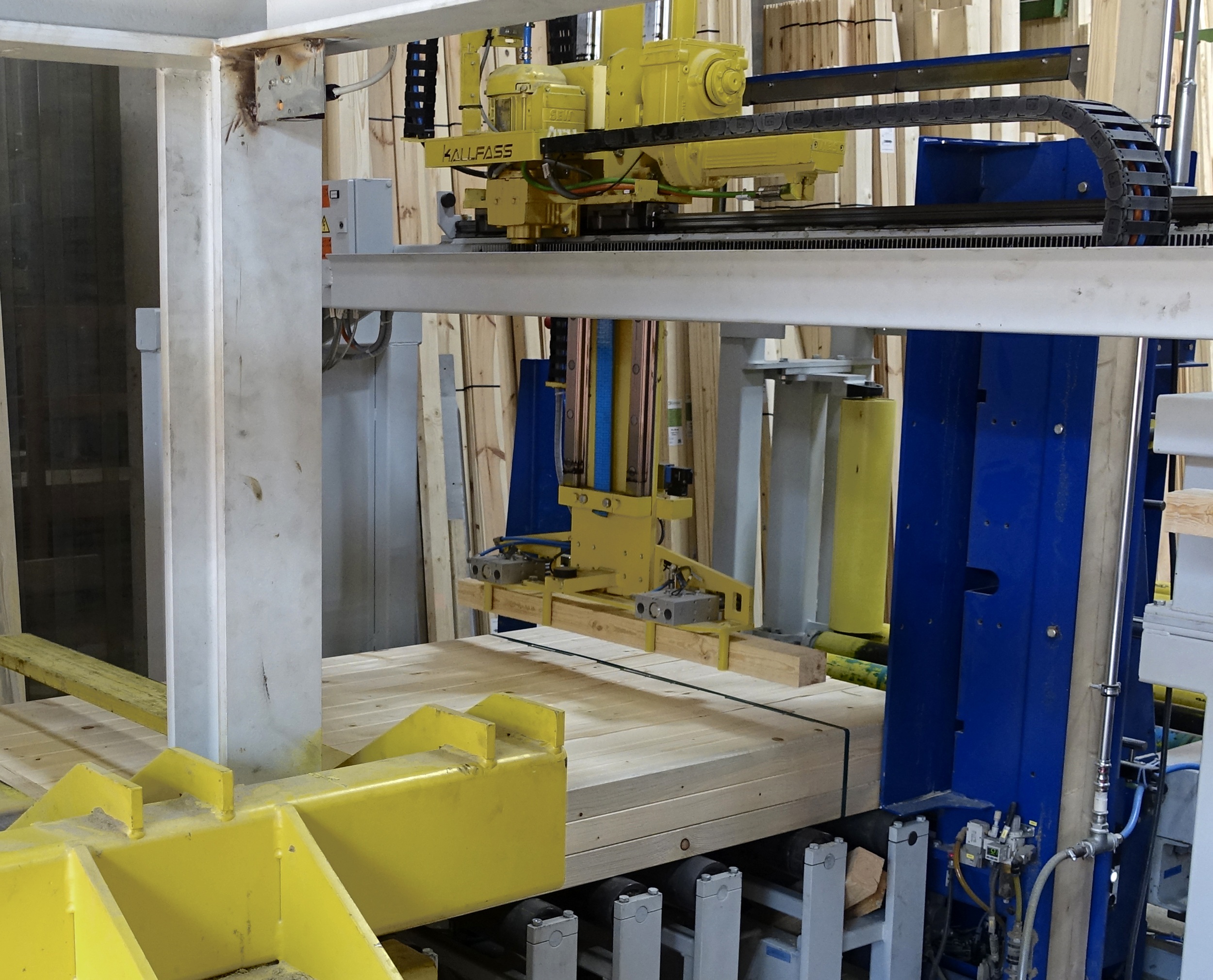

Kallfass takes charge of the main product upstream of the two multi-blade saws. A vertical system transports the separated logs as a whole to a peel-off system. Aided by gravity, these form a veritable carpet of boards. After passing a visual inspection station, layers are formed and the boards are cut at both ends before being fed layer by layer to a stacker.

Separated logs are transported to the Kallfass peel-off system to create layers of boards.

Adequate capacity

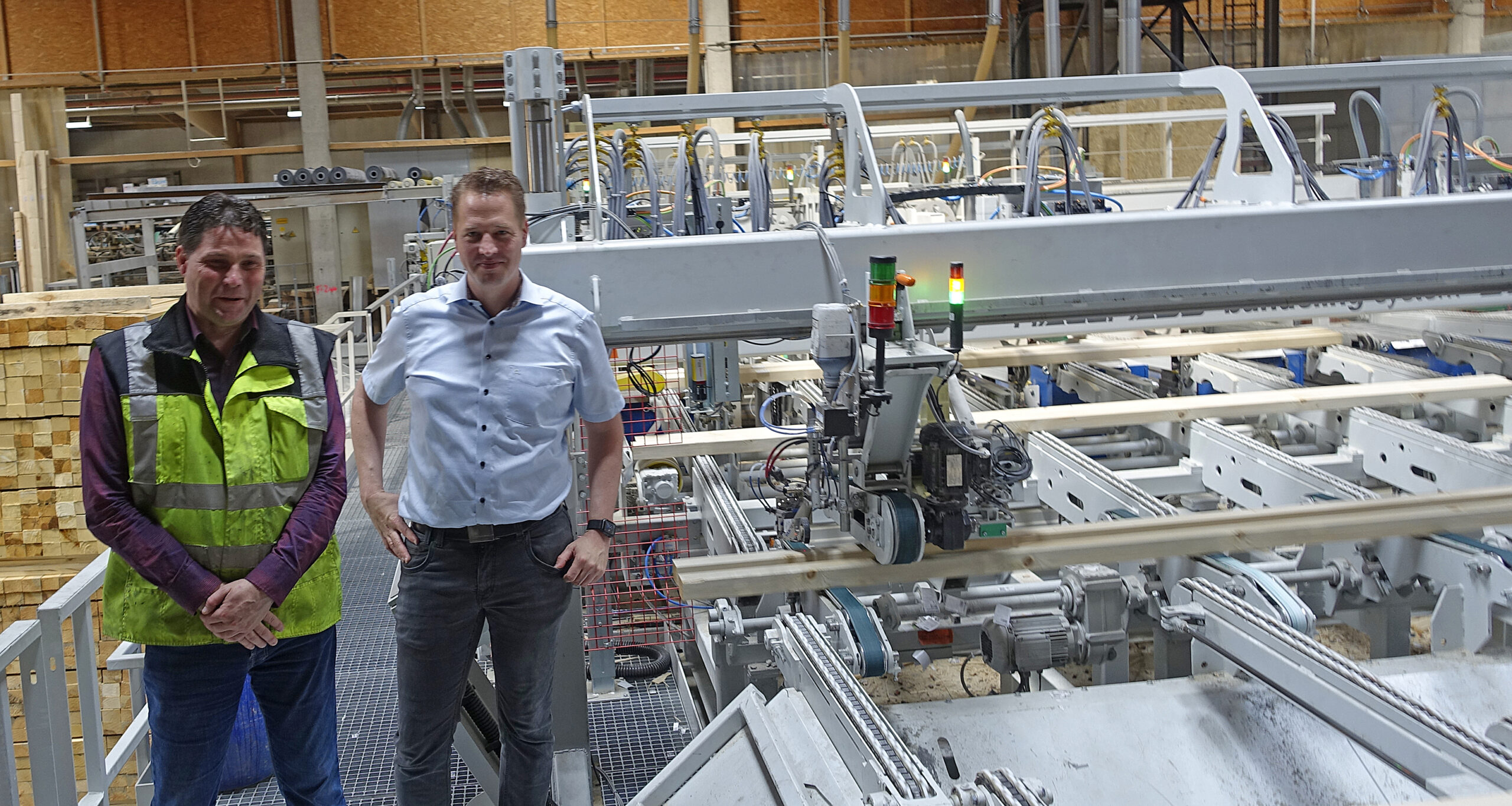

Kallfass collects the side boards in buffer levels. “As we had little experience with these short dimensions, the design was partially based on assumptions that, ultimately, worked out very well indeed”, reported Kallfass Project Manager Matthias Link.

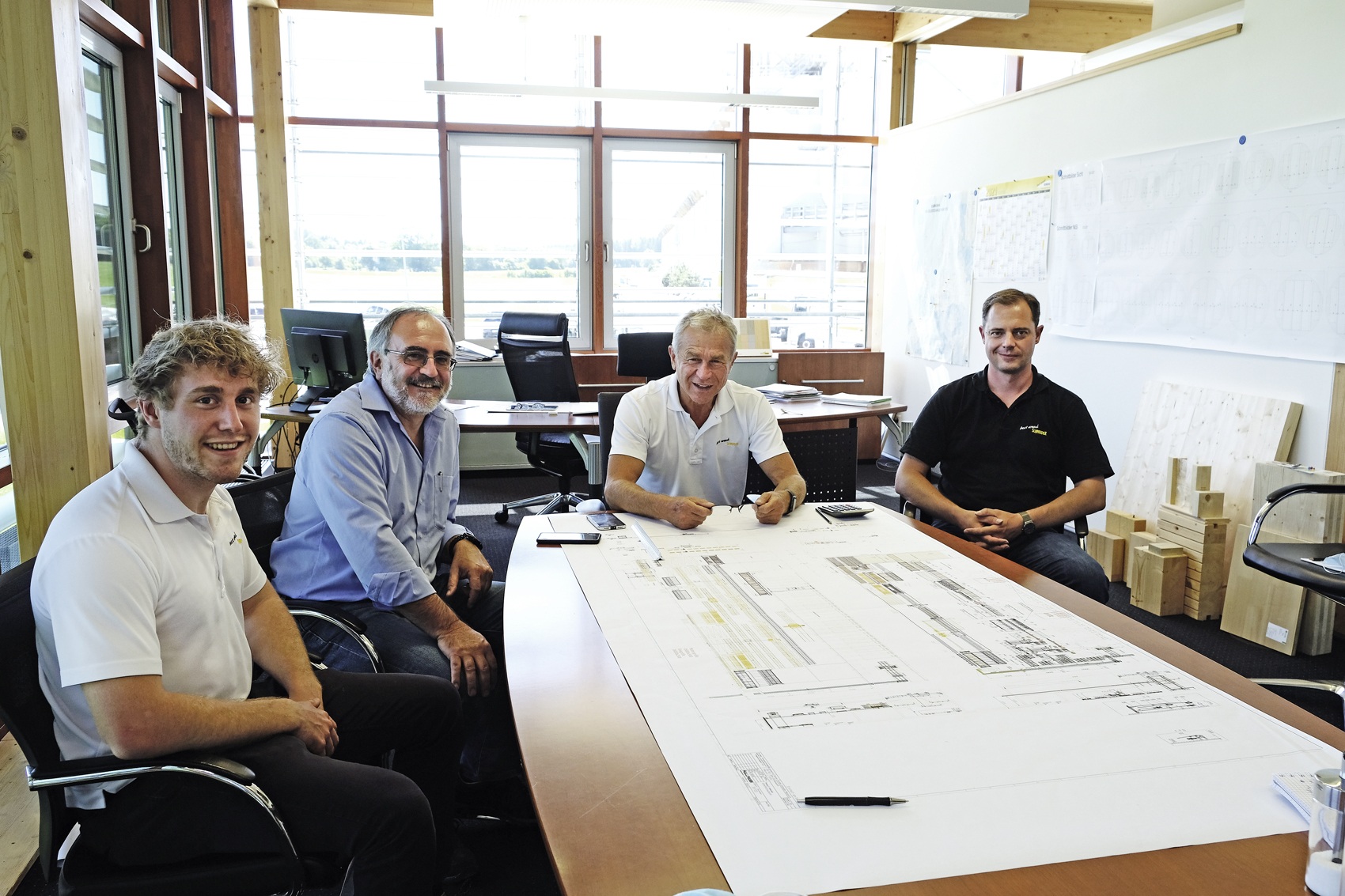

Solution-oriented approach

This was neither the first nor the last joint project for Kallfass and Juodeliai. The German plant engineers had already been involved in a greenfield project for the Lithuanian timber industry in 2014. “We’re delighted to have opted again for Kallfass. They never try to offer us prefabricated solutions, but rather concentrate on our ideas and implement these. This practical approach is the main reason we decided to work with Kallfass again”, emphasised Andrius Zimnickas, adding that the next project, a second main product stacking system for Marijampole, has already been commissioned. This will be commissioned in the 1st quarter of 2024 at the latest.

Application of an impregnation agent

Separated logs are transported to the Kallfass peel-off system to create layers of boards.

Kallfass sorting conveyor for ejecting unsuitable products.

Side view of the products buffered in 4 levels.